Indoor energy-saving LED display screen and use method thereof

An LED display screen, energy-saving technology, applied in the field of display screen, can solve the problems of cumbersome adjustment work, structure curing, etc., to achieve the effect of flexible space occupation position, avoid cumbersome process, avoid unnecessary loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

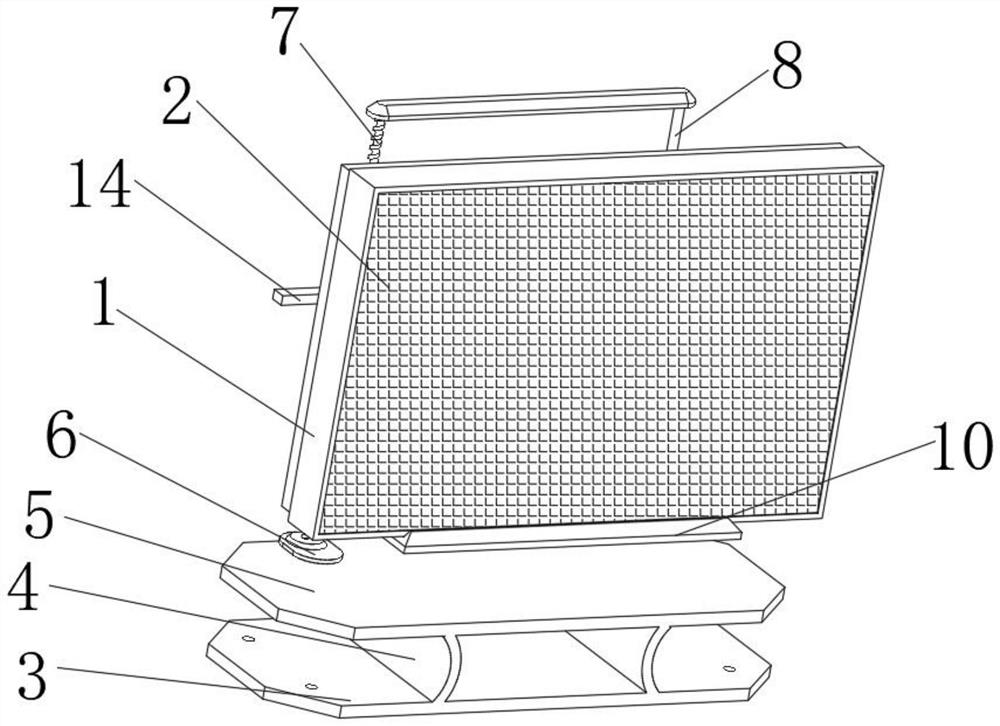

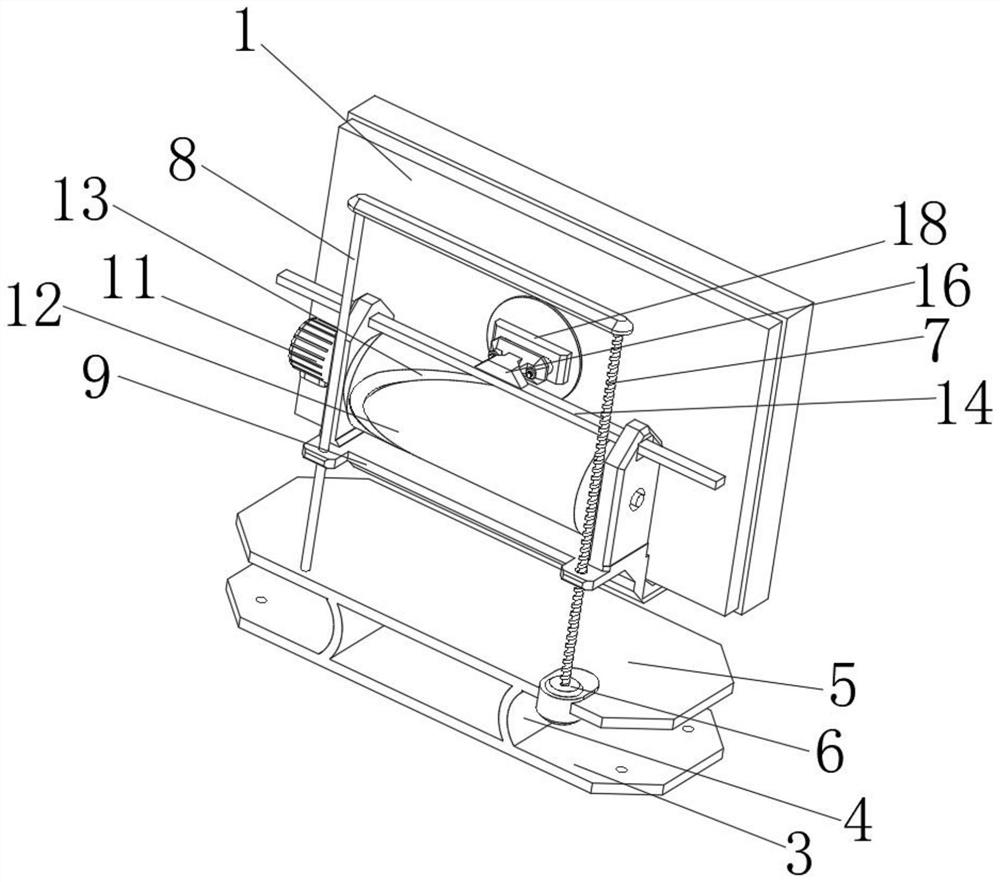

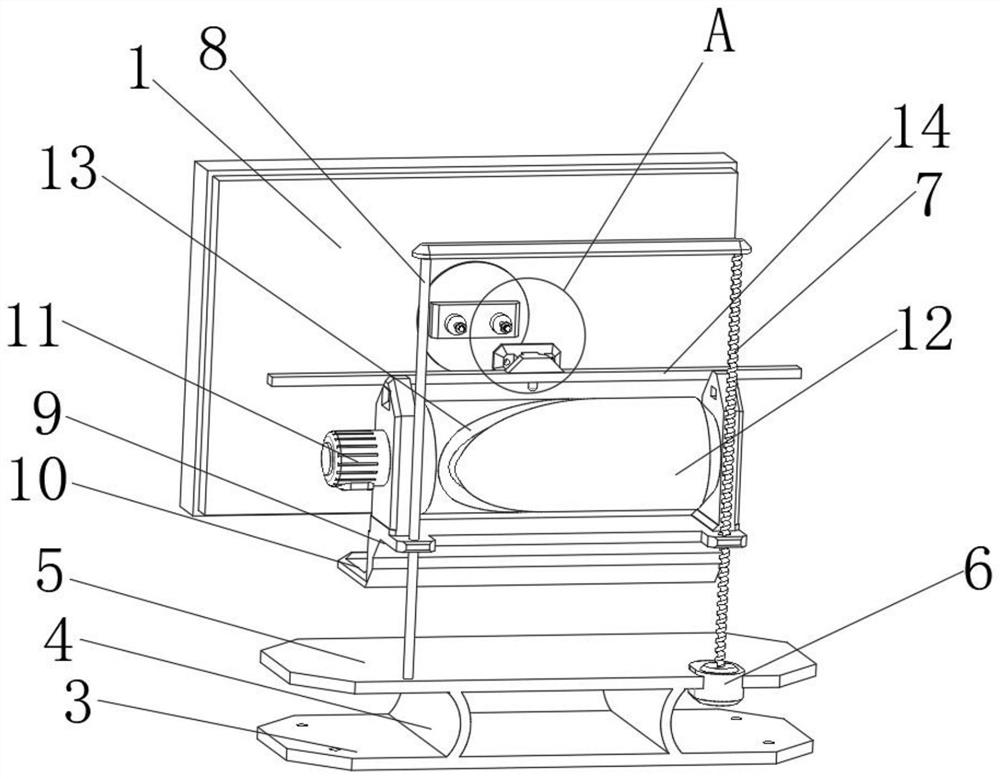

[0034] see Figure 1-4 , the present invention provides a technical solution: an indoor energy-saving LED display screen, comprising a casing 1, the inner front of the casing 1 is equipped with a screen 2, and the display function of the display screen can be realized through the screen 2, and the display function of the casing 1 can be realized. The bottom surface is provided with a bottom plate 3, the upper surface of the bottom plate 3 is provided with a support plate 4 on both sides, the upper surface of the support plate 4 is provided with a support plate 5, and the rear end of the support plate 5 is equipped with a No. Provide stable support for the operation of No. 1 motor 6. The shape of the support plate 4 is arc. The purpose of this design is to provide the support plate 5 with a space for force buffering through the arc shape of the support plate 4, so that the support plate The structure of 5 is more stable. The four corners of the upper surface of the base plate 3...

Embodiment 2

[0037] see Figure 3-4 , the connecting mechanism includes a connecting frame 16, a connecting plate 17 and a rear end frame 18, the connecting frame 16 is installed at the center position of the front end of the guide rod 14, the connecting plate 17 is fixedly connected with the connecting frame 16, and the rear end frame 18 is installed in the housing 1. The center position of the rear end. The purpose of this design is to realize the position fixing function of the rear end frame 18 and the connecting plate 17. Both sides of the rear end of the rear end frame 18 are equipped with pressure rods 19, and the rear end of the pressure rod 19 is equipped with a pressure rod 19. Insertion rod 20, both sides of the rear end of the connecting plate 17 are provided with jacks 21, the inserting rod 20 is inserted in the inner side of the jacking hole 21, the pressing rod 19 is fitted with the connecting plate 17, and the inserting rod 20 is inserted into the jacking hole 21 The inner ...

Embodiment 3

[0039] see Figure 5-6 , the inner side of the casing 1 is equipped with a circuit board 23, the circuit board 23 is electrically connected with the screen 2, and the display content of the screen 2 can be controlled through the circuit board 23, the inner and lower surface of the casing 1 is equipped with a water collecting tank 24, which collects The inner side of the water tank 24 is filled with the cooling liquid. The purpose of this design is to realize the filling function of the cooling liquid. The other end of 25 is equipped with a cooling pipe 27, and one end of the cooling pipe 27 is equipped with a return pipe 28. Both the suction pipe 26 and the return pipe 28 are inserted into the inner side of the water collecting tank 24. The purpose of this design is to construct the circulation of the cooling liquid. The self-circulation function of the cooling liquid is realized by the suction pump 25. The upper surface of the water collecting tank 24 is equipped with a place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com