Deformable variable-frequency sound absorption device

A technology of sound-absorbing devices and cavities, which is applied in sound-generating devices, additive processing, instruments, etc., can solve the problems of low service life of porous foam, difficulty in frequency conversion and noise reduction, and small range of frequency band changes, achieving excellent surface quality, Effect of reducing stress concentration and improving overall firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

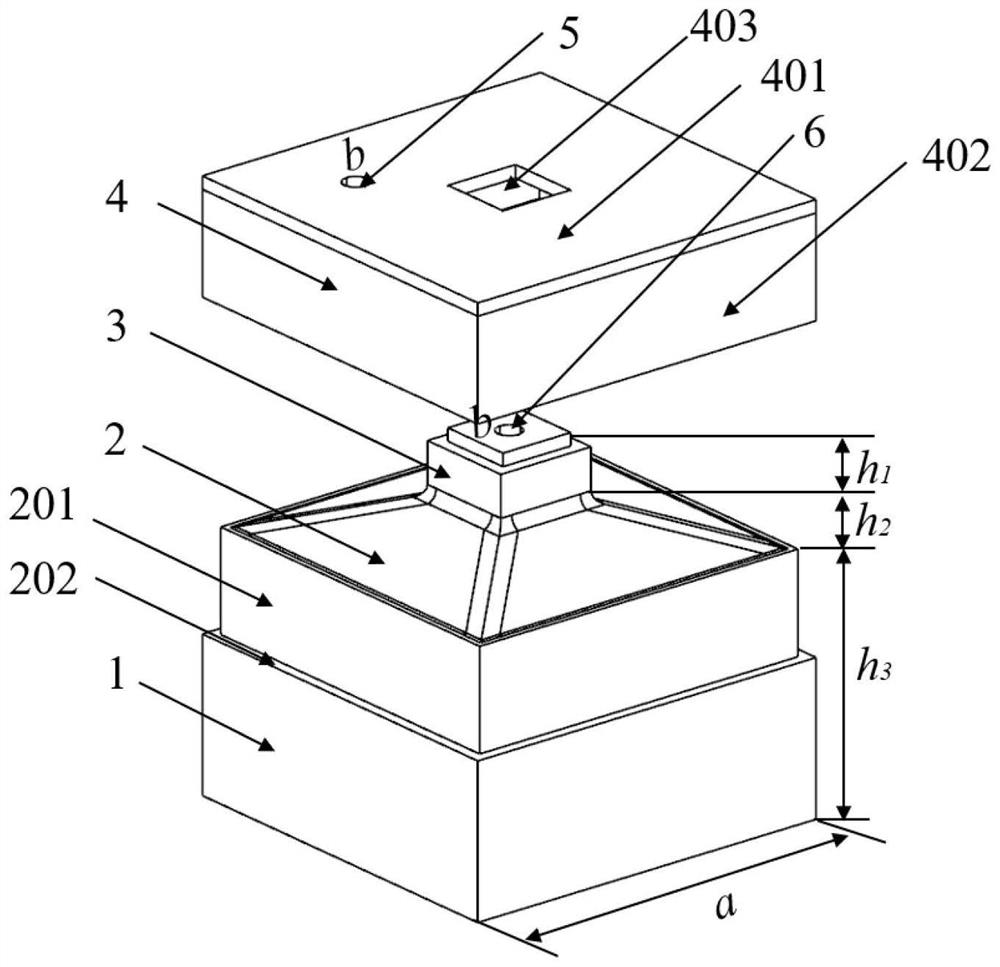

[0054] The deformable frequency conversion sound absorption structure is designed by CAD software. The bottom cavity structure and the support part are cubes, that is, the bottom surface of the bottom cavity structure and the support part are square, the length and width of the bottom cavity structure are 30mm, and the height of the support part is h 1 =4mm, the height of the camber bulge h 2 =3mm, bottom cavity height h 3 = 20mm, the length and width of the support are 8mm, the length and width of the boss of the support part are 7mm, and the height is 1mm.

[0055] The thickness of the bottom cavity structure is 1mm, the wall thickness of the convex arc surface is 0.5mm, the wall thickness of the support part is 1mm, the length and width of the inner wall of the side wall of the top cover are both 29mm, and the thickness is 0.5mm. The length and width of the bottom cavity boss are equal to the length and width of the inner wall of the side wall of the top cover, and the hei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com