LED packaging structure and preparation method of LED packaging structure

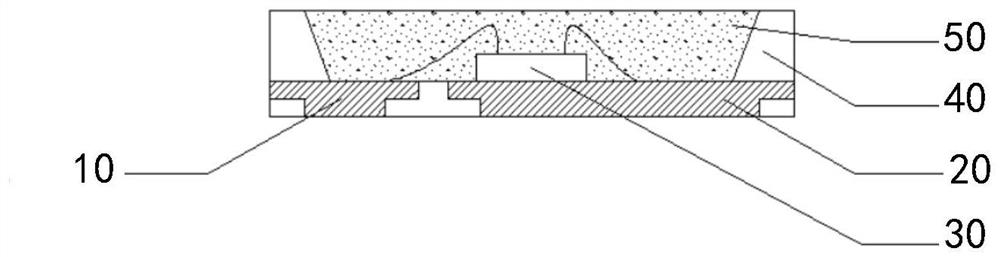

A technology of LED packaging and LED chips, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as the inability to achieve a 180° light-emitting angle and a small light-emitting angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] For LED devices, the light-emitting angle is a very important parameter. The larger the light-emitting angle, the wider the illumination area of an LED device and the more areas that can be illuminated. The current LED device has a light-emitting angle of an LED lamp. The maximum can only reach about 120°, and it is almost impossible to reach 180°. Therefore, in view of the above problems, the application provides an LED package structure, so that the light-emitting angle of an LED lamp can reach 180°, and it can also ensure that each The brightness of the angle is close.

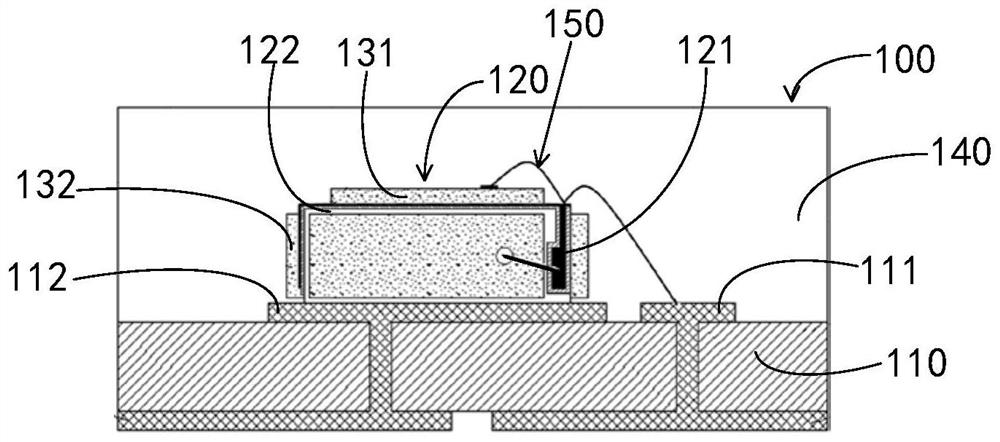

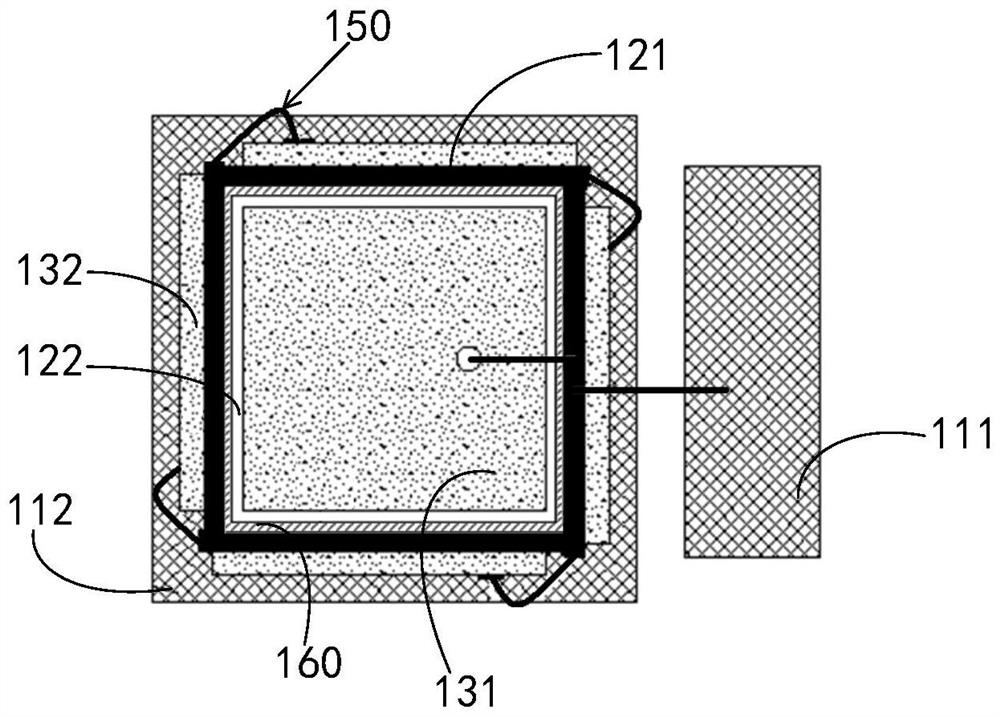

[0042] This embodiment provides an LED package structure, including: a substrate, on which a first pad and a second pad are arranged; a carrier, where the bottom surface of the carrier is fixed on the substrate, and the carrier is There are third pads and fourth pads, the third pads configured to partially cover the top surface of the carrier and extending to each side, the fourth pads configured t...

Embodiment 2

[0064] This embodiment also provides a preparation method of the LED packaging structure, and the preparation method of the LED packaging structure includes:

[0065] S01: A substrate and a carrier are provided, a first pad and a second pad are arranged on the substrate, a third pad and a fourth pad are arranged on the carrier, and the third pad is configured to partially cover the top surface of the carrier and extending to each side, the fourth pad being configured to partially or fully cover the top surface of the carrier and extending to each side and bottom;

[0066] S02: the carrier is fixed on the substrate, and the fourth pad on the bottom surface of the carrier is welded to the second pad of the substrate;

[0067] S03: Weld and fix the LED chip on each surface of the carrier except the bottom surface, the LED chip is a vertical structure chip, and the bottom electrode of the LED chip is bonded and welded on the fourth pad on the surface where it is located;

[0068]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| beam angle | aaaaa | aaaaa |

| beam angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com