Bean threshing device and threshing machine

A technology of threshing device and thresher, which is applied in the direction of threshing equipment, agricultural machinery and implements, agriculture, etc., can solve the problems of winding and clogging of threshing device, and achieve the effect of preventing winding and blocking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

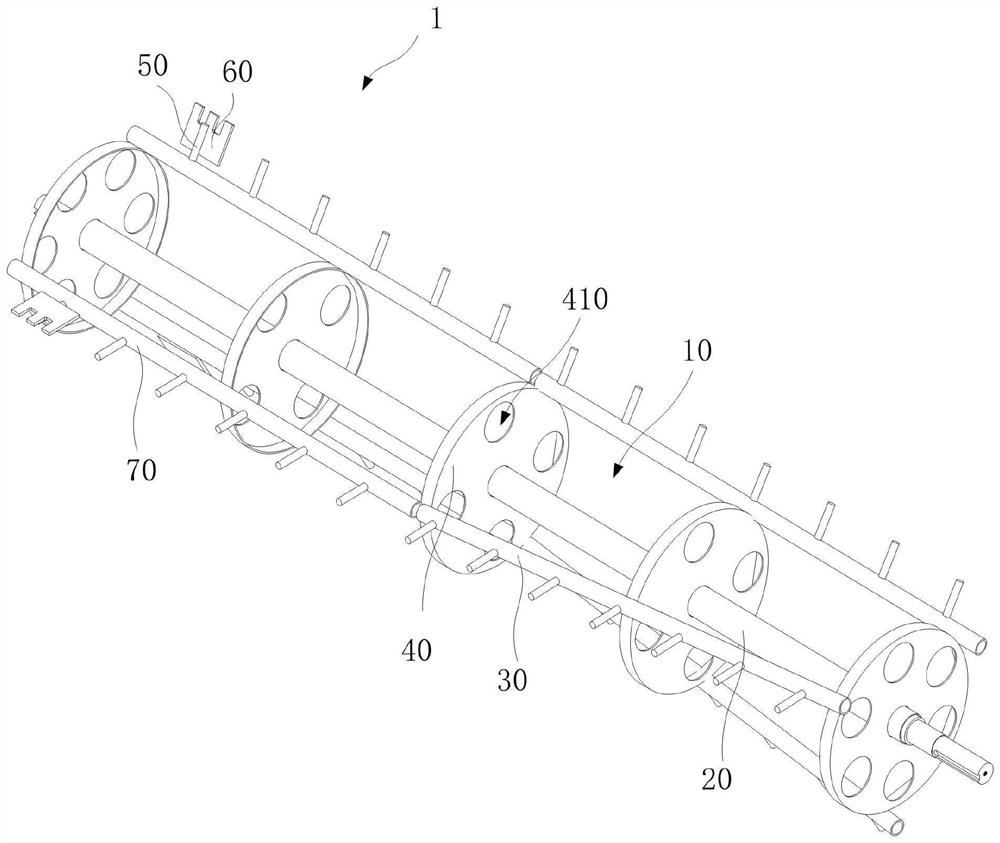

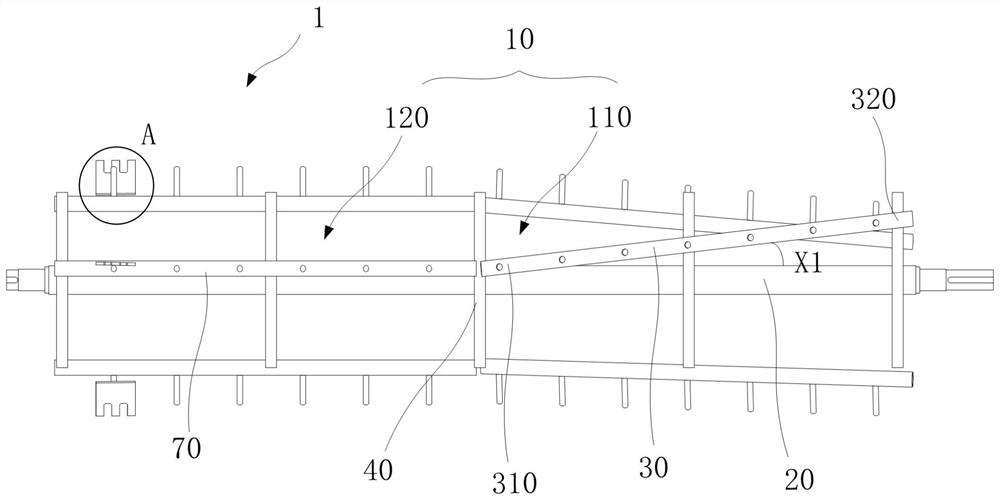

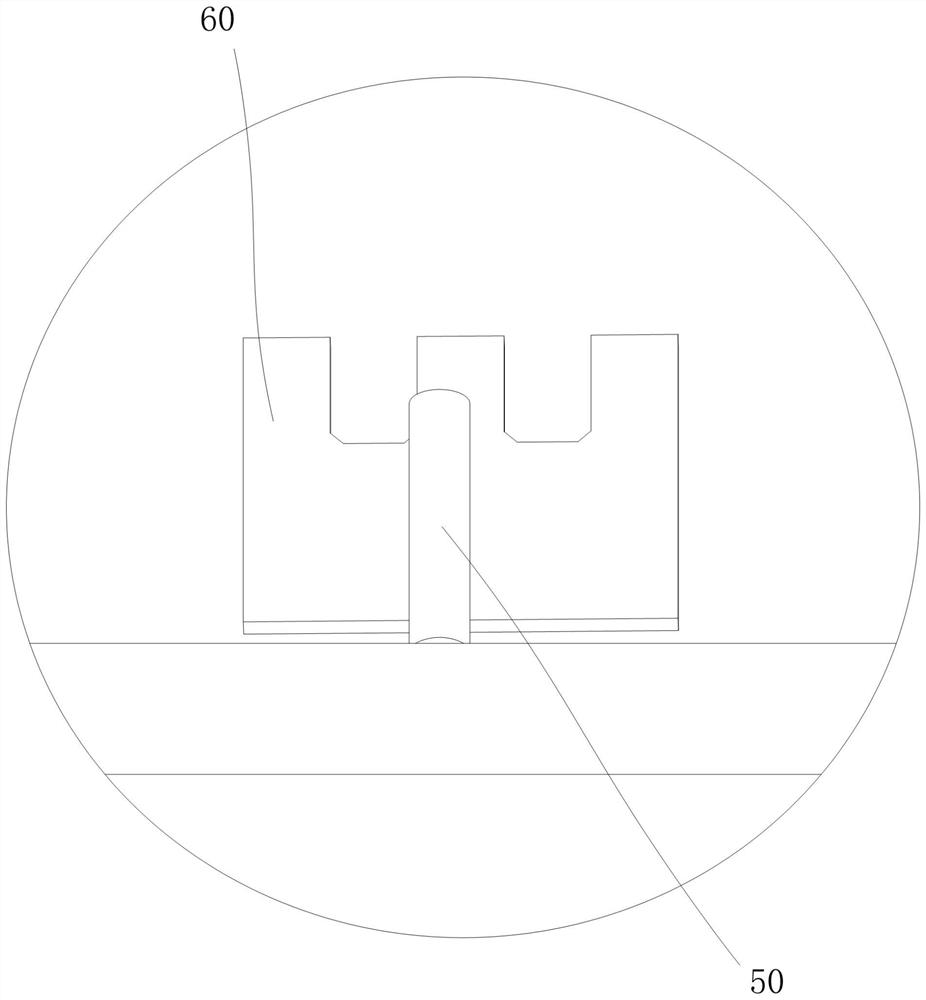

[0035] see figure 1 and figure 2 , This embodiment provides a bean threshing device 1, including: a storage cavity 10, the storage cavity 10 is used for placing straw for threshing; a rotating shaft 20, the rotating shaft 20 passes through the storage cavity 10, and the rotating shaft 20 is used to drive the threshing device 1 to rotate; The first threshing rod 30 is disposed on the outer periphery of the storage cavity 10 , and the first threshing rod 30 is inclined relative to the rotating shaft 20 .

[0036] In this embodiment, the threshing device 1 is used for the threshing of beans, specifically, it relates to the threshing of broad beans. The threshing device 1 is specifically a threshing drum, and the threshing device 1 is surrounded by a plurality of A space for temporarily placing straw for threshing, this space is the storage cavity 10 in this embodiment.

[0037] Wherein, the first threshing rod 30 in this embodiment is a part of a plurality of threshing rods. ...

Embodiment 2

[0040] see Figure 1 to Figure 2 In this embodiment, the storage cavity 10 includes: a first threshing area 110, the outer periphery of the first threshing area 110 is provided with a first threshing rod 30; a second threshing area 120, the outer periphery of the second threshing area 120 is provided with a Two threshing rods 70 ; wherein, the first threshing rod 30 drives the straw from the first threshing area 110 to the second threshing area 120 for threshing.

[0041] In this embodiment, the first threshing zone 110 is the first position where the straw is fed into the threshing device 1 . figure 2 As shown, the first threshing area 110 is located on the right side, the second threshing area 120 is located on the left side of the first threshing area 110, and the threshing bar set at the peripheral position of the first threshing area 110 is the first threshing bar 30, and the second threshing area The threshing rod set at the peripheral position of the zone 120 is the s...

Embodiment 3

[0044] see Figure 1 to Figure 2 , the threshing device 1 further includes: a web 40, the web 40 is provided with a first through hole 410, the web 40 is inserted into the storage cavity 10, the first threshing rod 30 and the second threshing rod 70 are connected with the web 40, And the web 40 separates the first threshing zone 110 from the second threshing zone 120 .

[0045] In this embodiment, the web 40 is a metal circular plate-like structure. Similarly, the first threshing rod 30 and the second threshing rod 70 are also made of a hard metal. The rotating shaft 20 passes through the web 40, that is, the web 40 is fixedly connected with the rotating shaft 20, the web 40 separates the first threshing area 110 from the second threshing area 120, and the first threshing rod 30 is the same as the second threshing rod 70 Connected with the web 40, the web 40 has the function of strengthening the first threshing rod 30 and the second threshing rod 70, which can make the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com