Digital detonator batch potting packaging structure and potting method

A technology of digital detonator and packaging structure, applied in the field of digital detonator, can solve problems such as low efficiency of potting process, and achieve the effects of solving low efficiency, improving reliability, and preventing moisture damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention is further described below. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and cannot be used to limit the protection scope of the present invention.

[0041] An embodiment of the present invention provides a method for batch potting of digital detonators, and the specific implementation process is as follows:

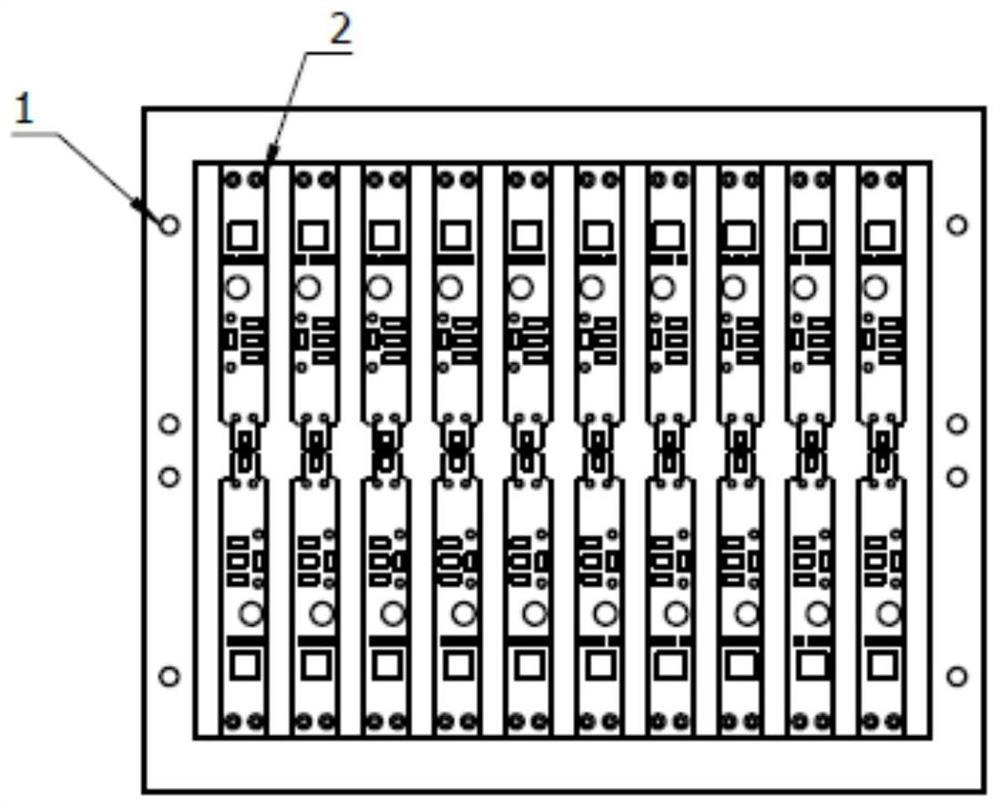

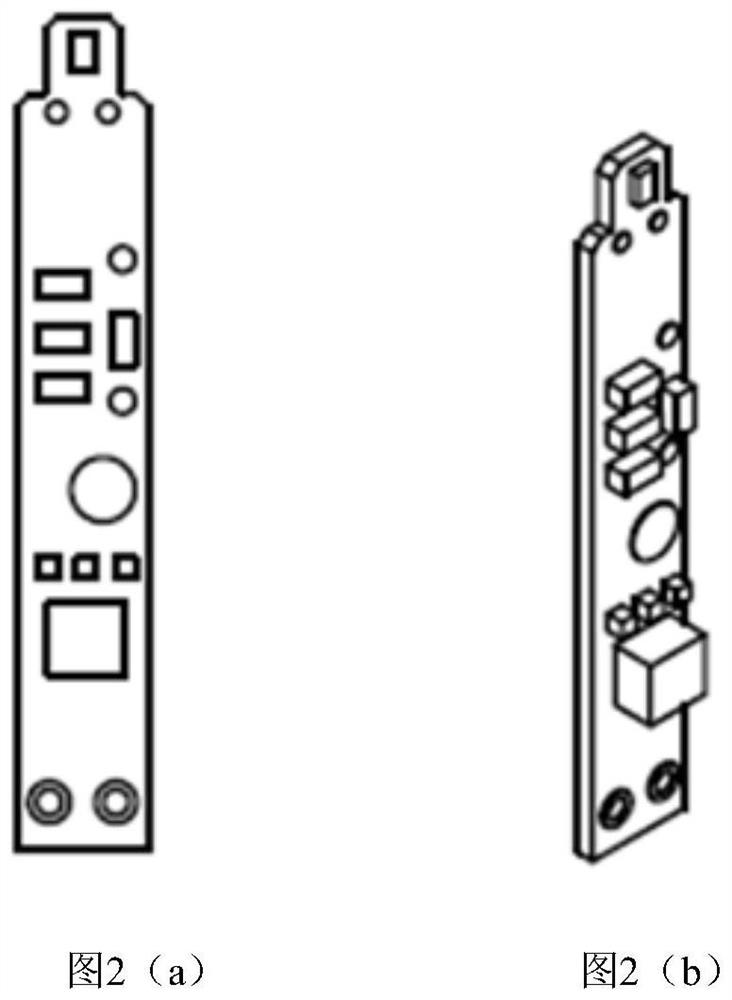

[0042] (1) Design and process multi-row and multi-shot digital detonators on PCB substrate 2, and directly perform patch processing on the PCB substrate to obtain as follows: figure 1 The unpotted digital detonator PCB board shown, the unpotted single shot digital detonator is as figure 2 (a) and figure 2 (b) shown.

[0043] It should be noted that each digital detonator and the substrate are pre-cut by wire cutting in advance, but not all of them are cut, so that the digital detonator can be easily removed from the substrate in the later stage.

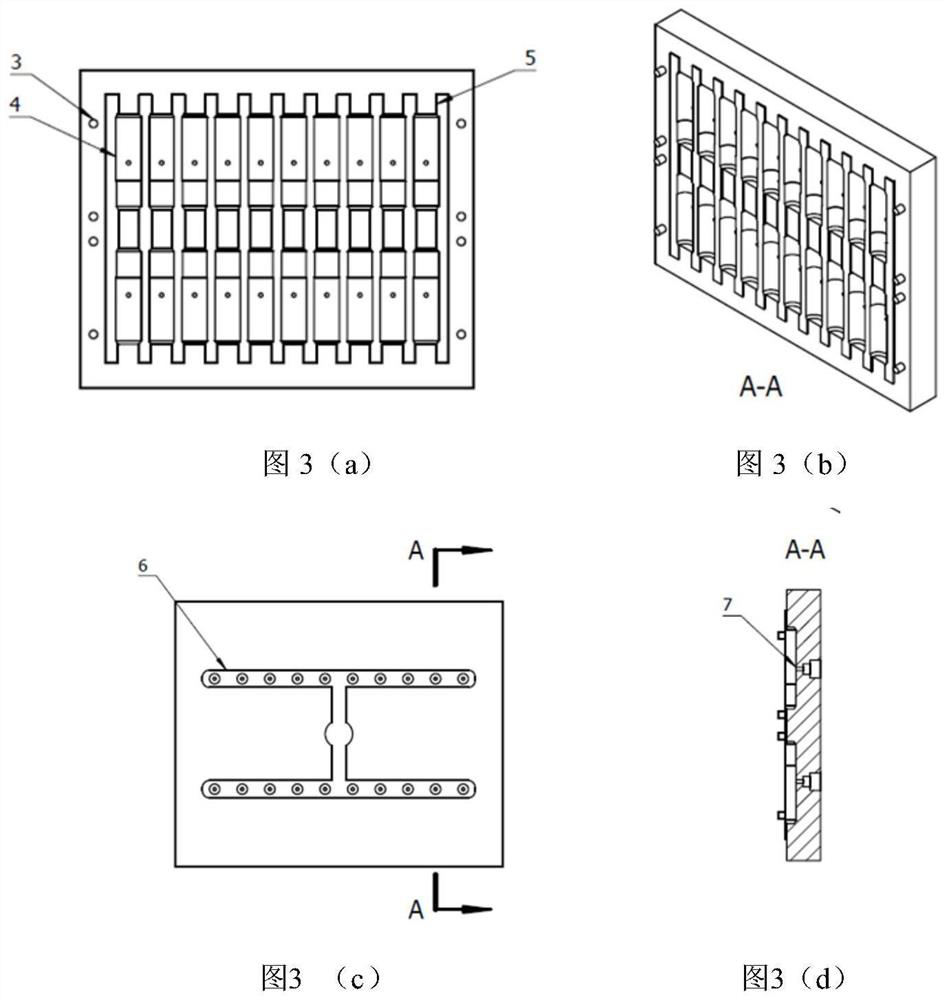

[0044] (2) Place the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap