Tension calibration calculation method and device

A calculation method and technology of a calculation device, which are applied in the directions of transportation and packaging, thin material processing, winding strips, etc., can solve problems such as errors, and achieve the effect of improving production quality and eliminating errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

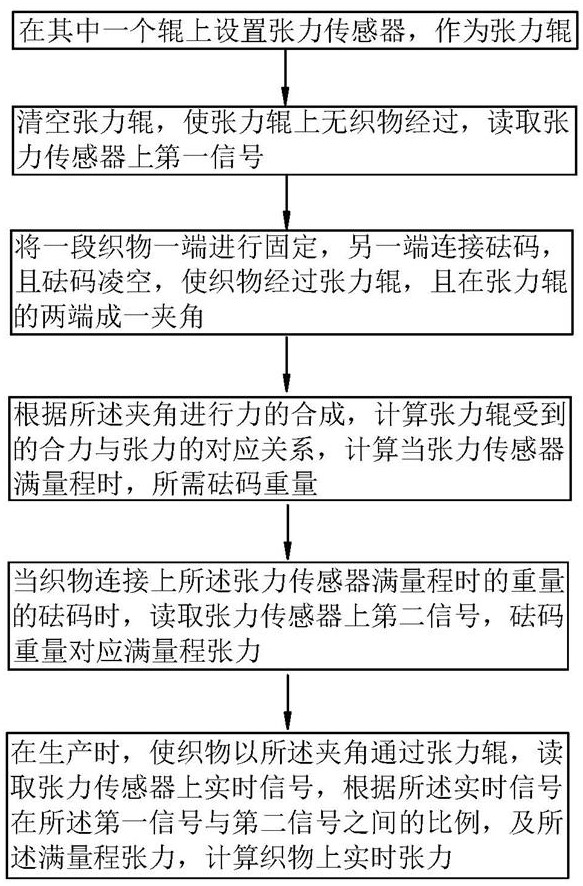

[0041] like figure 1 Shown: a tension calibration calculation method, including the following steps:

[0042] Set a tension sensor on one of the rollers as a tension roller;

[0043] Empty the tension roller so that no fabric passes on the tension roller, and read the first signal on the tension sensor;

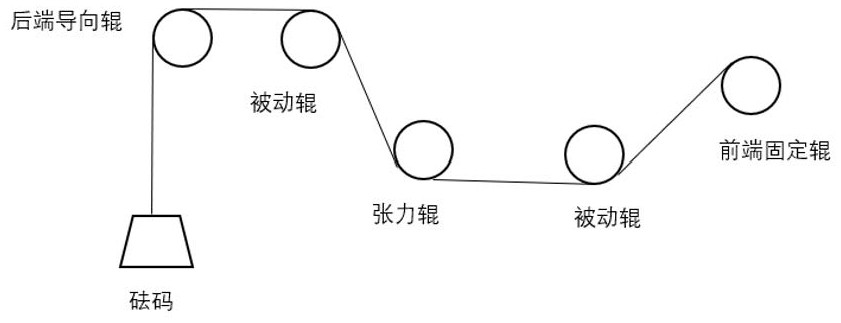

[0044] One end of a piece of fabric is fixed, and the other end is connected with a weight, and the weight is volleyed, so that the fabric passes through the tension roller and forms an angle at both ends of the tension roller;

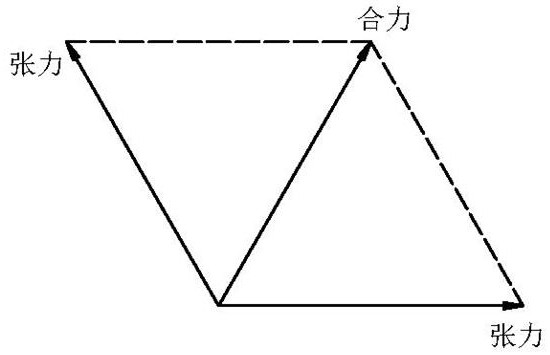

[0045] The force is synthesized according to the angle, and the corresponding relationship between the result...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com