Reverse process manufacturing method to ensure the coaxiality of the trunnion of the large-scale converter support ring

A technology of large-scale converters and manufacturing methods, applied in the direction of manufacturing tools, metal processing equipment, welding equipment, etc., can solve the problems affecting the swimming side, affecting the long trunnion, affecting steelmaking production, etc., to eliminate the benchmark welding deformation, reduce Accumulative superposition of deformation, beneficial to the effect of steelmaking production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

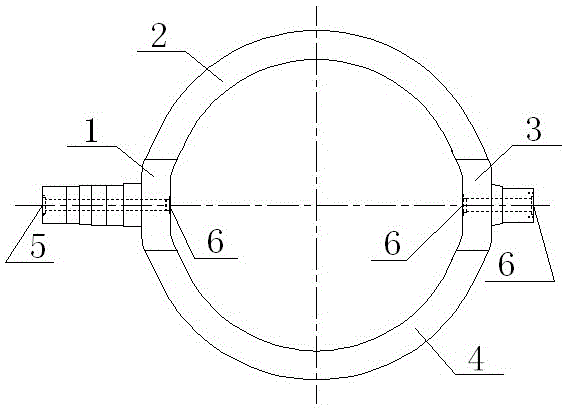

[0033] Depend on figure 1 It can be seen that the large-scale converter support ring is composed of a driving side trunnion block 1, a tapping side sector 2, a traveling side trunnion block 3 and a feeding side sector 4. Using the reverse process, the production method is carried out according to the following steps:

[0034] 1. Set up the assembly platform Use steel plates and H-shaped steel to build the assembly platform and level it at the construction site, and the flatness is not greater than 1.0mm.

[0035] 2. Draw a line on the platform to draw the center line of the cross based on the two trunnion blocks 1, 3 and the position lines of the trunnion blocks 1, 3 and the sectors 2, 4.

[0036] 3. Laser detection The two trunnion blocks 1 and 3 are placed on the assembly platform and aligned with the center line and position line; the laser device 5 is set at the left end of the driving side trunnion, the target target 6 is set at the right end, and the target target 6 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com