Steel strand tie bar cable system with layered and separated wire supporting structure and mounting method of steel strand tie bar cable system

A supporting structure and steel strand technology, which is applied in the erection/assembly of bridges, arch bridges, buildings, etc., can solve the problems of high labor intensity, large number of steel strands, labor and working hours, and save manpower and working hours , application advantages and obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

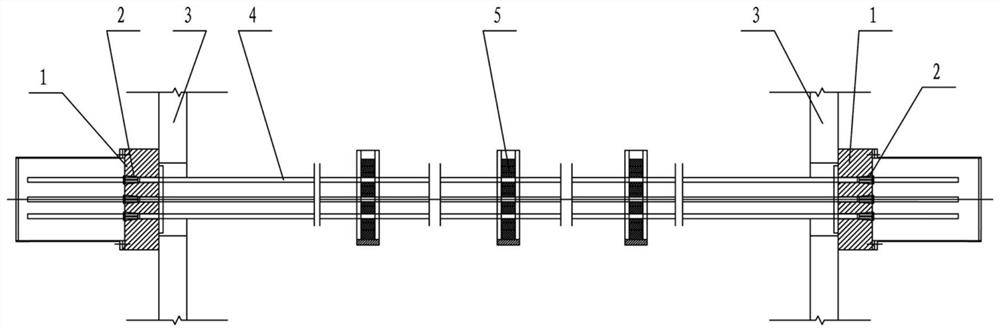

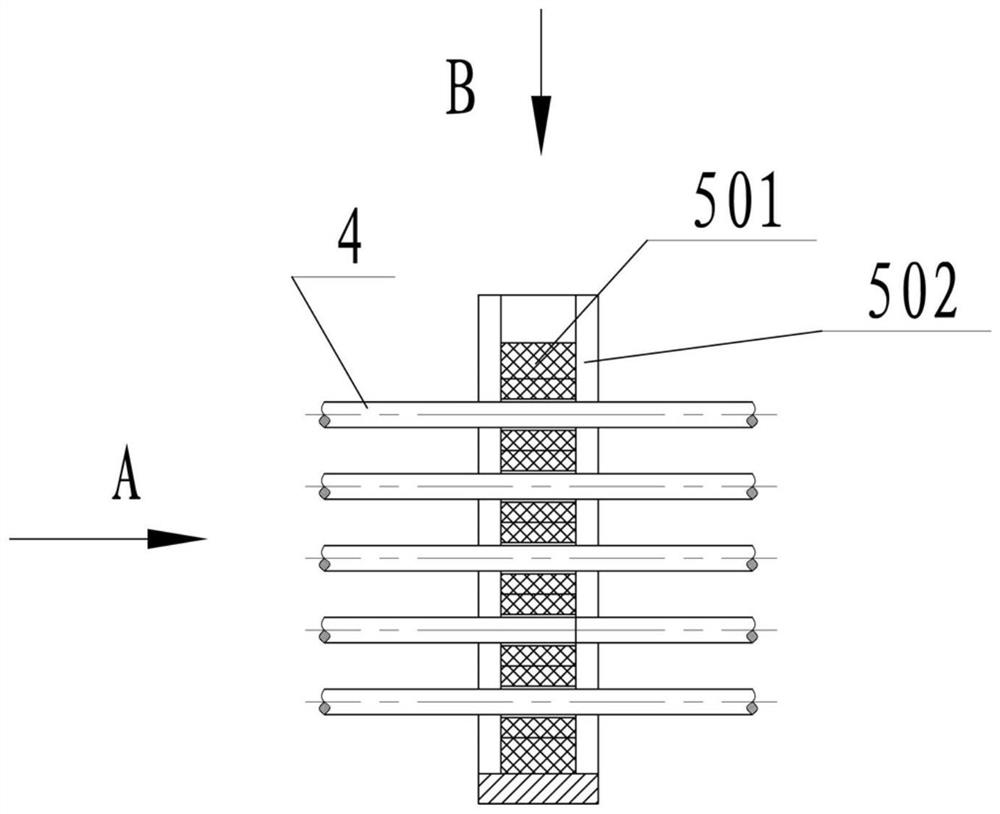

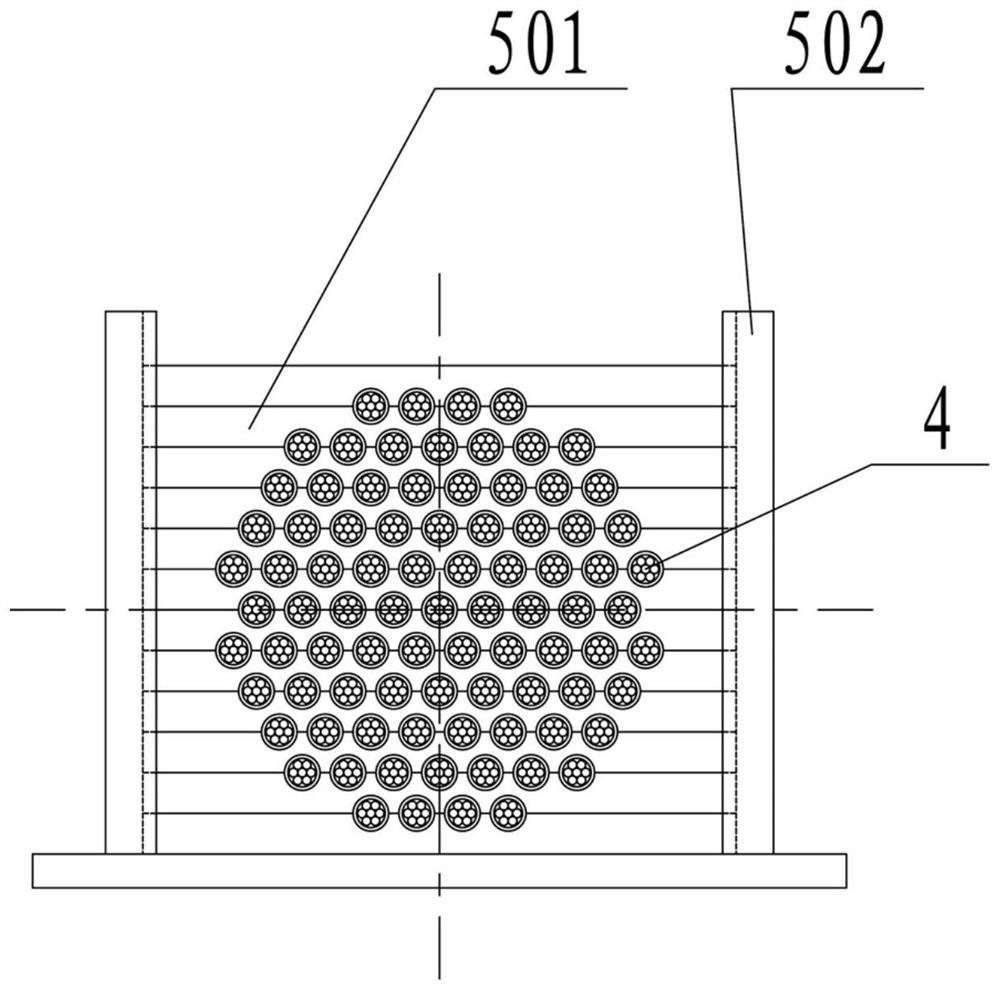

[0061] like Figure 1 to Figure 10As shown, a steel strand tie rod system with a layered split wire support structure in this embodiment includes two left and right anchor point engineering structures 3, and anchor points are provided on the anchor point engineering structures 3. Tool 1, a steel strand wire body is inserted between the left and right anchors 1, the anchor tool 1 includes a plurality of conical anchoring holes, the steel strand wire body includes a plurality of steel strands 4, a plurality of steel strands The wire 4 corresponds to a plurality of conical anchoring holes one-to-one. An anchoring clip 2 is embedded in the conical anchoring hole. The steel strand 4 is fixed to the anchor 1 through the anchoring clip 2. A plurality of supporting frames 5 are arranged at intervals on the left and right of the cable body, and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com