PCB (printed circuit board) tin spraying assembly line with water-saving equipment

An assembly line and equipment technology, applied in the cleaning/polishing of conductive graphics, separation methods, filtration and separation, etc., can solve the problems of high water cleanliness, unfavorable saving of water resources, and poor recycling, so as to save water resources , the effect of large coverage area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

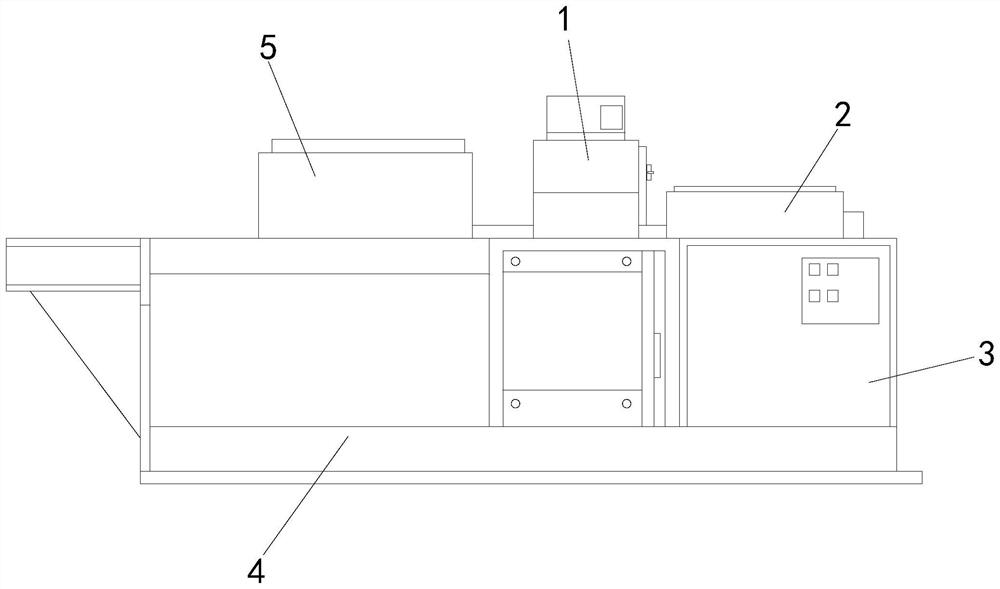

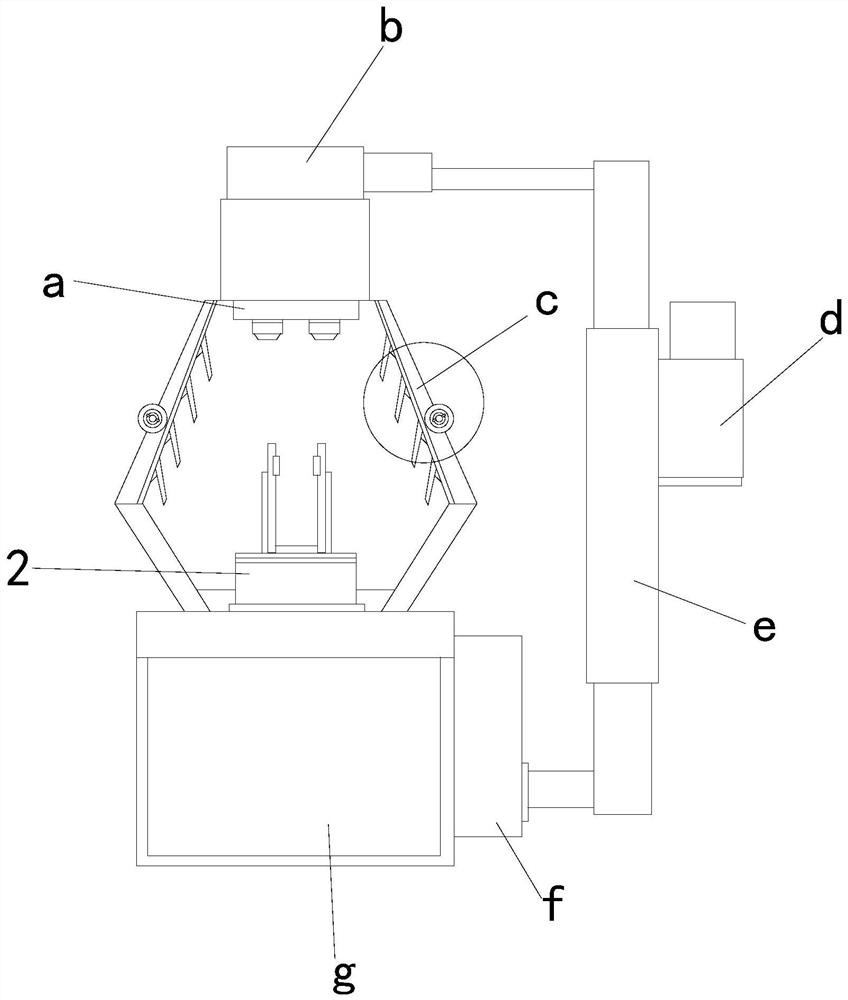

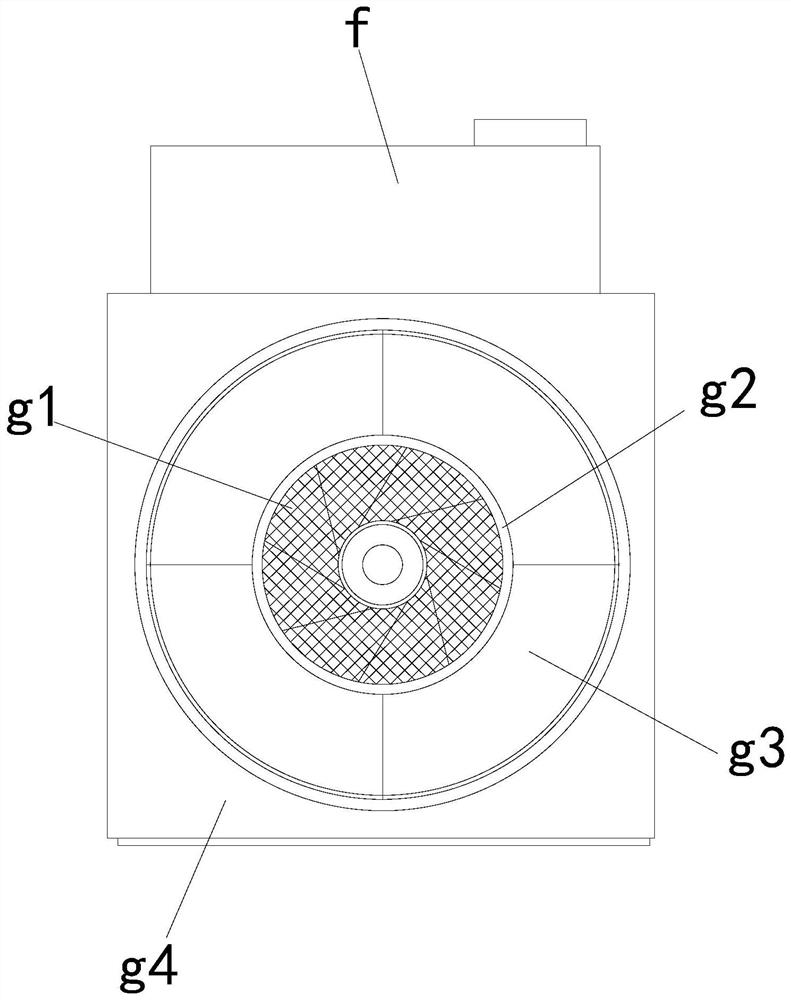

[0024] see Figure 1-Figure 3 , The present invention provides a technical solution for a pcb tin spraying line with water-saving equipment: its structure includes: a water washing bin device 1, a clamping and feeding table 2, a control mechanism 3, a bearing base 4, and an air-drying box device 5. The air-drying box The device 5 is installed on the left side of the water washing bin device 1 and is buckled with the water washing bin device 1. The right side of the water washing bin device 1 is provided with a clamping and feeding table 2, and the clamping and feeding table 2 is slidingly matched with the water washing bin device 1. A control mechanism 3 is arranged under the clamping and feeding table 2, a bearing base 4 is arranged under the control mechanism 3, and the bearing base 4 is locked with the control mechanism 3. The water washing bin device 1 includes a nozzle device a, a plus Pressure outer cylinder b, baffle device c, water pump device d, transfer pipe e, purif...

no. 2 example

[0028] see Figure 4-Figure 5 , The present invention provides a technical solution for a pcb tin spraying line with water-saving equipment: its structure includes: the baffle device c includes an assembly outer frame c1, a guide shaft c2, a knob block c3, a movable baffle device c4, a front Mounting plate c5, the knob block c3 is arranged on the front side of the guide shaft c2 and is buckled with the guide shaft c2, the inner side of the guide shaft c2 is provided with a movable blocking device c4, and the movable blocking device c4 is set in the The inner side of the outer frame c1 is assembled, and the front side of the outer frame c1 is provided with a front mounting plate c5.

[0029] The movable blocking device c4 includes an upper push rod c41, a linkage ring c42, a lower push rod c43, a support block c44, and an inner guide plate c45. The upper push rod c41 is installed above the support block c44 and welded with the support block c44, A linkage ring c42 runs through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com