Aerator with filter screen

An aerator and belt filter technology, applied in the field of aerators, can solve the problems of inconvenient cleaning, blockage of the aerator, affecting work efficiency, etc., and achieve the effect of facilitating later use and reducing the frequency of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

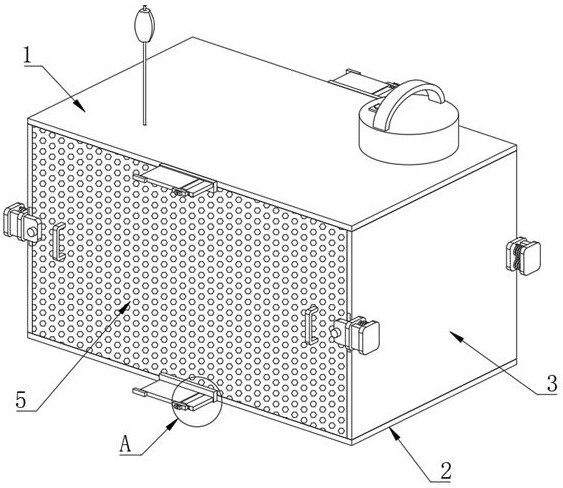

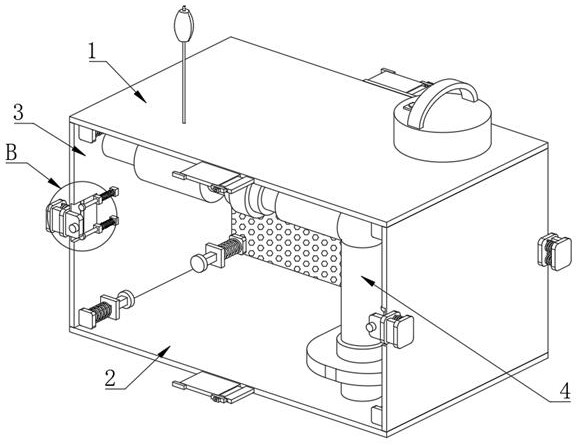

[0034] Example one, by Figure 1 to Figure 9 Given, the present invention comprises a top plate 1, a bottom plate 2 and an aerator body 4, the aerator body 4 is located between the top plate 1 and the bottom plate 2, the top plate 1 and the bottom plate 2 are connected by two side plates 3, and the aerator body 4 Both sides are provided with a filter screen 5, and the adjacent side of the two side plates 3 are provided with two chute 6, one side of the inner wall of the chute 6 is communicated with one side of the side plate 3, the filter screen 5 is Both sides are fixedly connected with a sliding plate 8, and two first baffles 7 are provided on one side of the two filter screens 5 away from each other. There is an elastic pressing component matched with the filter screen 5, and the top plate 1 and the bottom plate 2 are provided with an anti-fall component matched with the filter screen 5;

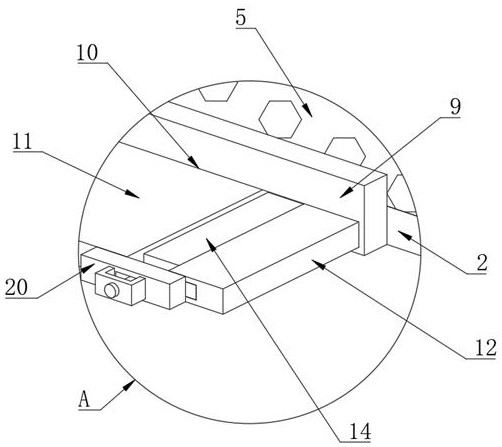

[0035]The anti-fall assembly includes two first fixing plates 9 arranged on the filt...

Embodiment 2

[0036] Embodiment 2, on the basis of Embodiment 1, by figure 1 , image 3 , Figure 5 , Image 6 , Figure 7 and Figure 9 Given, one side of the movable plate 12 is provided with a second groove 17, a limit plate 18 is arranged in the second groove 17, and one side of the limit plate 18 and the inner wall of one side of the second groove 17 pass through two second grooves 17. Two compression springs 19 are connected, a second fixing plate 20 is fixedly connected to one side of the supporting plate 11, a limiting hole 21 is defined on one side of the second fixing plate 20, and a supporting frame 22 is fixedly connected to the second fixing plate 20. The supporting frame 22 is a U-shaped structure, one side of the support frame 22 is provided with a connecting rod 23, the connecting rod 23 penetrates the support frame 22, and one end of the connecting rod 23 is located in the limit hole 21, and both ends of the connecting rod 23 are fixedly connected to the limit plate 24...

Embodiment 3

[0038] Embodiment 3, on the basis of Embodiment 1, by figure 1 , figure 2 , Figure 4 and Figure 8 Given, the elastic pressing assembly includes a push plate 25 and a third fixing plate 26, the third fixing plate 26 is fixedly connected with the side plate 3, a prism 27 is fixedly connected to one side of the pushing plate 25, and the prism 27 penetrates the third fixing plate 26, A third compression spring 28 is sleeved on the outside of the prism 27, two ends of the third compression spring 28 are fixedly connected with the push plate 25 and the third fixing plate 26 respectively, and one end of the prism 27 away from the push plate 25 is fixedly connected with a first anti-fall. The plate 29, one side of the push plate 25 is in contact with one side of the filter screen 5, the reset unit includes a fourth fixing plate 30 arranged on one side of the first baffle 7, and the fourth fixing plate 30 is fixedly connected with the side plate 3, The first baffle plate 7 penetr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com