Secondary refining process for silver

An oxidative refining and secondary oxidation technology is applied in the field of precious metal smelting, which can solve the problems of low silver content in crude silver and low first-grade product rate of silver ingots, and achieve the effect of saving, reducing sodium hydroxide consumption and reducing requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be described in detail below with specific embodiments in conjunction with the accompanying drawings.

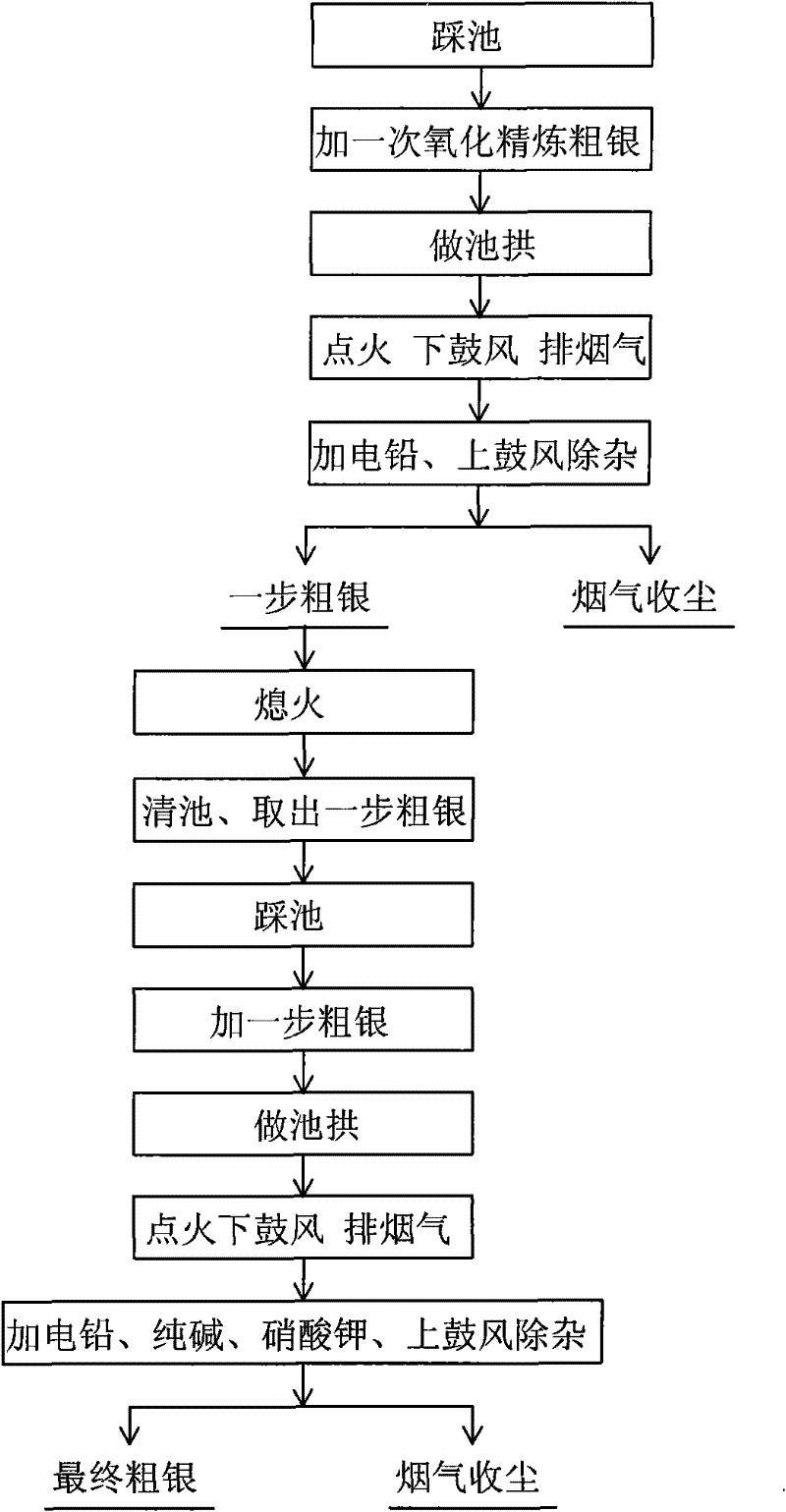

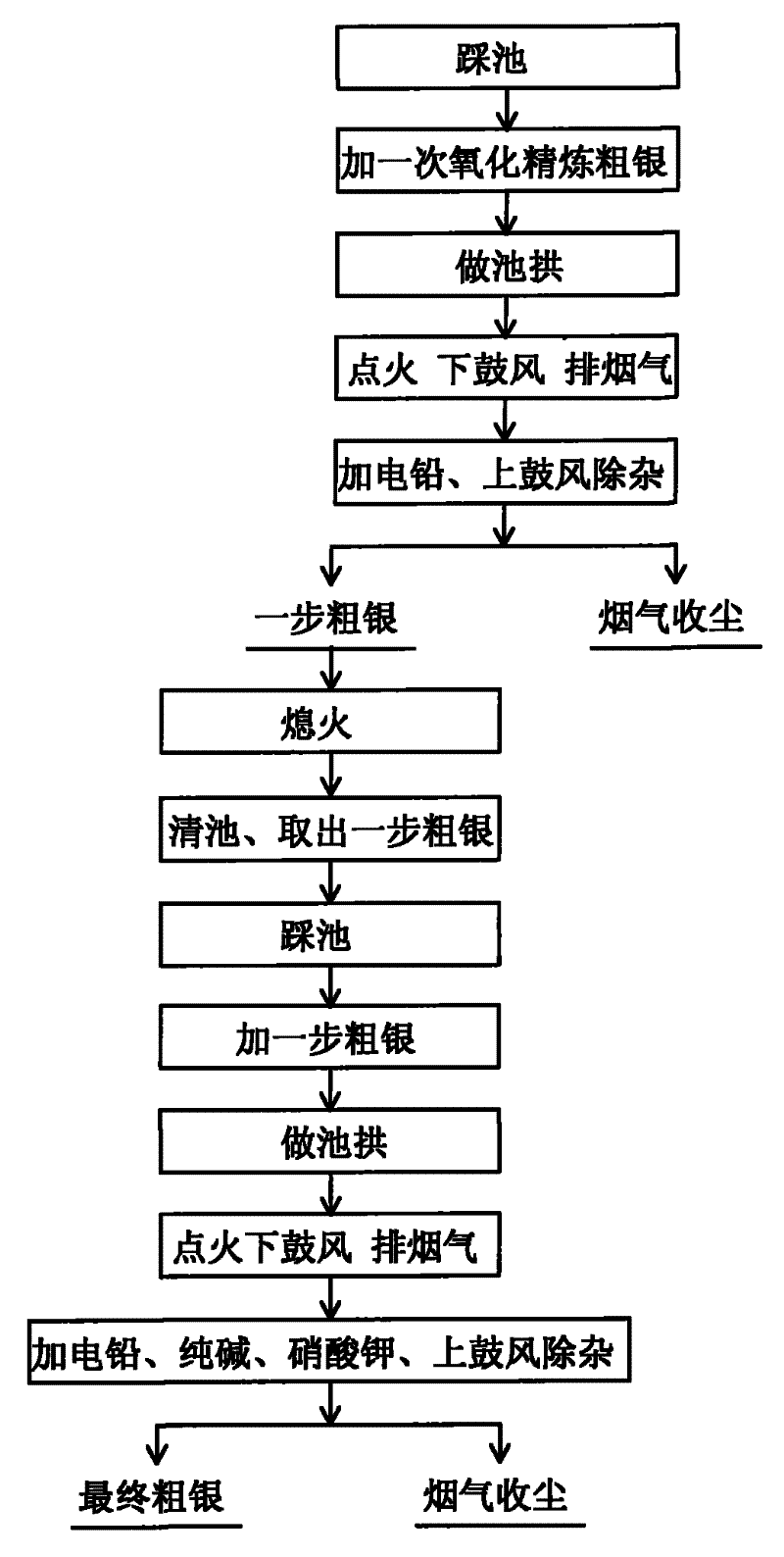

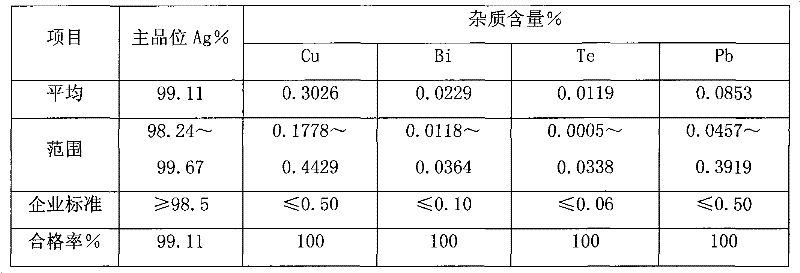

[0053] attached figure 1 It shows a secondary oxidation refining process diagram of silver, which is to add a blast after the small converter oxidation refining process of precious lead, and add lead oxidation refining process; this process is realized in a gray blown silver refining furnace, and its production capacity It is 150kg of crude silver per pool; the specific process is as follows:

[0054] ①Primary oxidation refining crude silver impurity removal process

[0055] 1a Stepping on the pool: Spread a layer of dry cement evenly on the bottom of the curved surface refining pool, and the amount of cement is one bag per pool;

[0056] 1b Add primary oxidized and refined crude silver: uniformly add primary oxidized and refined crude silver into the refining pool of the ashblowing silver refining furnace, the grade of primary oxidized an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com