Adjustable vacuum circuit breaker energy storage spring assembling and disassembling tool

A technology of vacuum circuit breaker and energy storage spring, applied in the field of adjustable vacuum circuit breaker energy storage spring loading and unloading tools, can solve the problems of easy deformation of the energy storage spring, difficult control of the energy storage spring, bullet damage to staff and equipment, etc. The effect of preventing popping or falling off, improving reliability, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

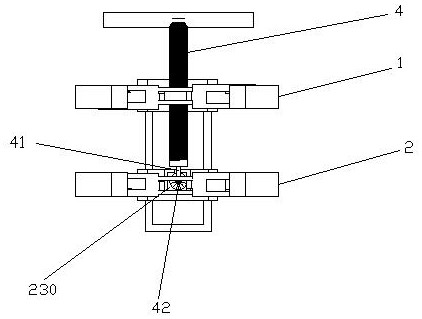

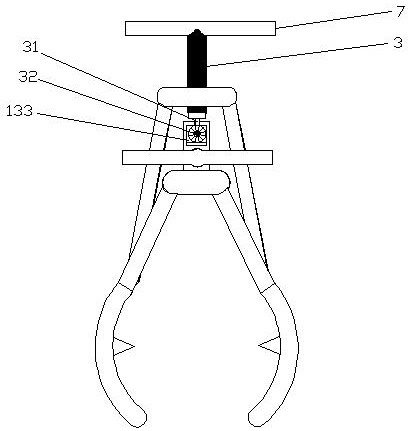

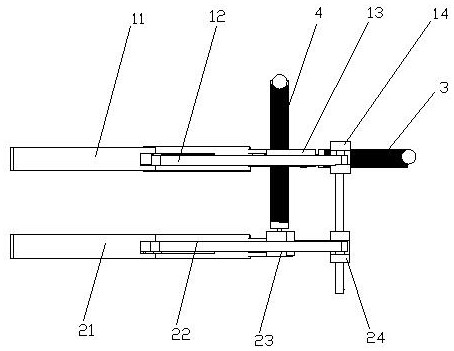

[0047] The present invention is as Figure 1-9 As shown, it includes an upper clamping arm assembly 1, a lower clamping arm assembly 2, a clamping screw 3 and a lifting screw 4,

[0048] The upper clamping arm assembly 1 includes a pair of upper clamping arms 11 , a pair of upper connecting rods 12 , an upper connecting plate 13 and an upper fixed clamping plate 14 , a pair of upper clamping arms 11 are symmetrically arranged, and the upper connecting rods 12 and the upper clamp The arms 11 are in one-to-one correspondence and are located on the outer side of the upper clamping arm,

[0049] One end of a pair of upper connecting rods 12 is symmetrically connected to both ends of the upper fixed clamping plate 14, and the other end is hingedly connected to the middle of the upper clamping arm 11.

[0050] The upper connecting plate 13 is located between a pair of upper connecting rods. The upper connecting plate 13 is T-shaped and has a horizontal section 131 and a vertical se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com