Underwater vehicle bionic dynamic variable-structure skin with intelligent self-adaptive resistance reduction function

An underwater vehicle, self-adaptive technology, applied in chemical instruments and methods, hydrodynamic characteristics/hydrostatic characteristics, ship construction, etc., can solve the problems of low drag reduction rate and no drag reduction, and achieve drag reduction High efficiency, reduced resistance, and reduced differential pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

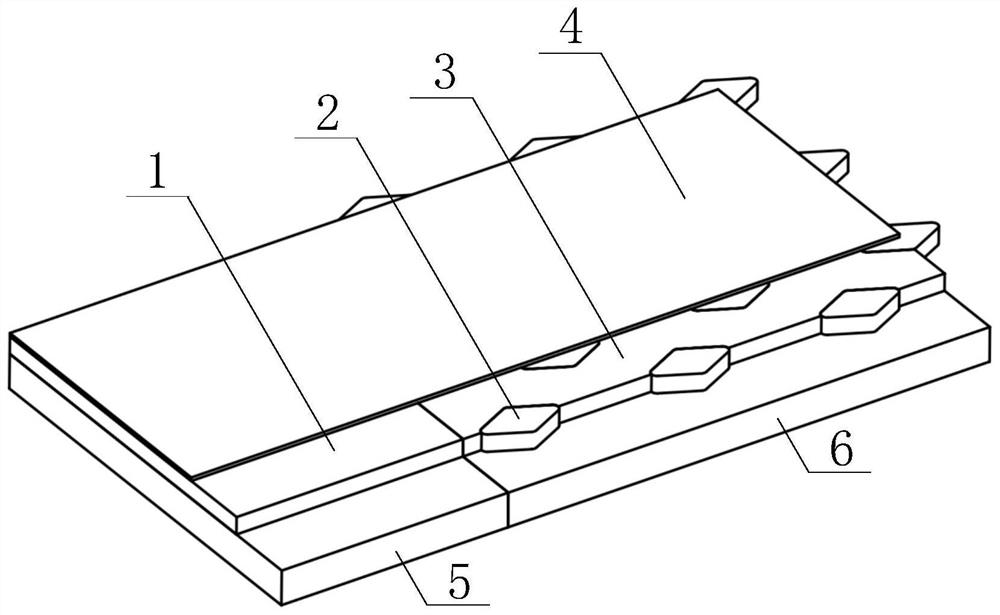

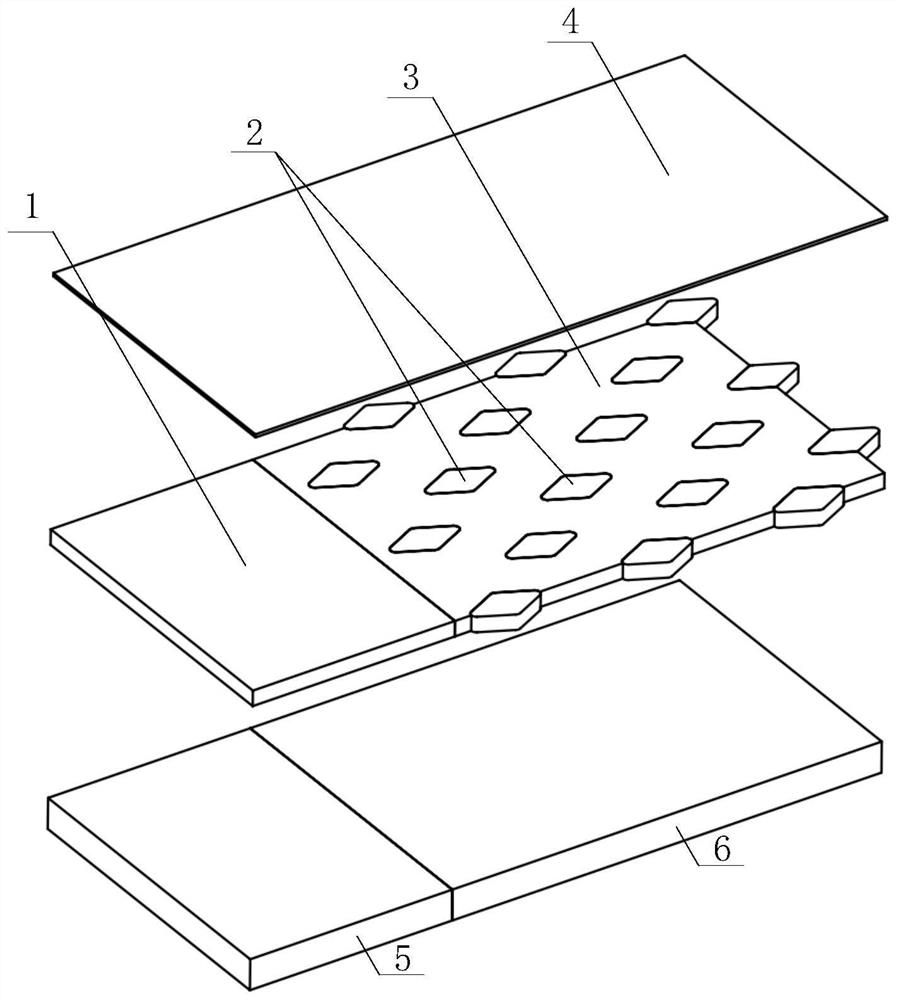

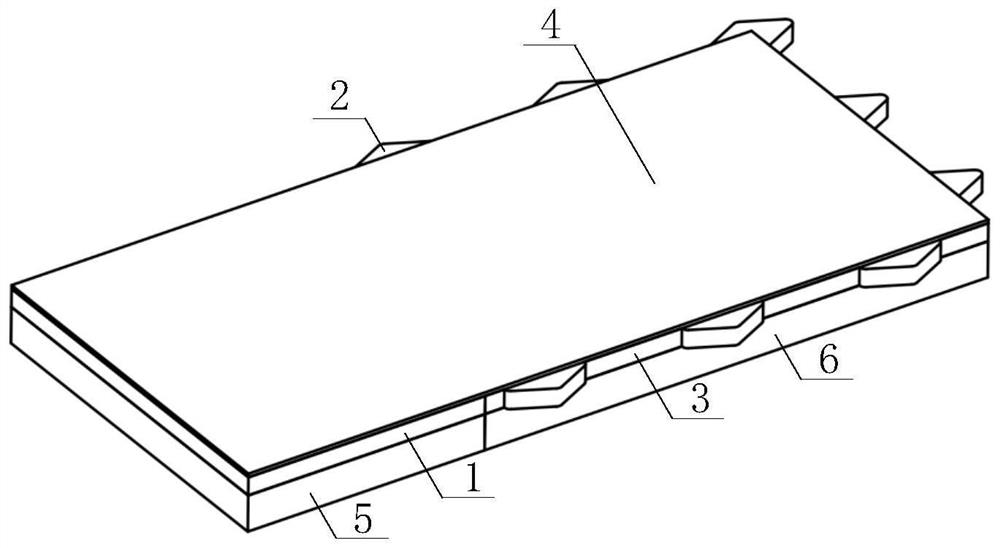

[0036] A biomimetic dynamic allosteric skin for underwater vehicle with intelligent adaptive drag reduction ( figure 1 , figure 2 ), including the front section and the rear section, the front section and the rear section are both composed of the top layer, the middle layer and the bottom layer, and the top layer of the front section and the rear section are both flexible organic polymer films, and the flexible organic polymer films are polymer films. Dimethylsiloxane film, the thickness of flexible organic polymer film is 0.3mm. The bottom layers of the front and rear sections are all ceramic heating pieces. The voltage of the ceramic heating piece is 5V and the power is 5W. The surface dry firing temperature of the ceramic heating piece is 90±5℃, and the thickness of the ceramic heating piece is 2mm. The middle layer of the front section is a temperature-controlled phase change material, the middle layer of the rear section is a metal (aluminum alloy) flat plate, the thick...

Embodiment 2

[0039] A biomimetic dynamic allosteric skin for underwater vehicle with intelligent adaptive drag reduction ( figure 1 , figure 2 ), including the front section and the rear section, the front section and the rear section are both composed of the top layer, the middle layer and the bottom layer, and the top layer of the front section and the rear section are both flexible organic polymer films, and the flexible organic polymer films are polymer films. Dimethylsiloxane film, the thickness of flexible organic polymer film is 0.5mm. The bottom layers of the front and rear sections are all ceramic heating pieces, the voltage of the ceramic heating piece is 5V and the power is 5W, the surface dry firing temperature of the ceramic heating piece is 90±5℃, and the thickness of the ceramic heating piece is 5mm. The middle layer of the front section is a temperature-controlled phase change material, the middle layer of the rear section is a metal (aluminum alloy) flat plate, the thick...

Embodiment 3

[0042] A biomimetic dynamic allosteric skin for underwater vehicle with intelligent adaptive drag reduction ( figure 1 , figure 2 ), including the front section and the rear section, the front section and the rear section are both composed of the top layer, the middle layer and the bottom layer, and the top layer of the front section and the rear section are both flexible organic polymer films, and the flexible organic polymer films are polymer films. Dimethylsiloxane film, the thickness of flexible organic polymer film is 0.4mm. The bottom layers of the front and rear sections are all ceramic heating pieces. The voltage of the ceramic heating piece is 5V and the power is 5W. The surface dry firing temperature of the ceramic heating piece is 90±5℃, and the thickness of the ceramic heating piece is 3mm. The middle layer of the front section is a temperature-controlled phase change material, the middle layer of the rear section is a metal (aluminum alloy) flat plate, the thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com