Dielectric barrier discharge plasma flat-plate turbulence flow drag reduction device

A dielectric barrier discharge and plasma technology, applied in the direction of plasma, electrical components, etc., can solve the problems of reducing the performance of aircraft, not applicable to aircraft engineering applications, and difficult to realize wall cooling method, and achieves novel structure, low manufacturing cost, and easy The effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the examples, the following examples are explanations of the present invention and the present invention is not limited to the following examples.

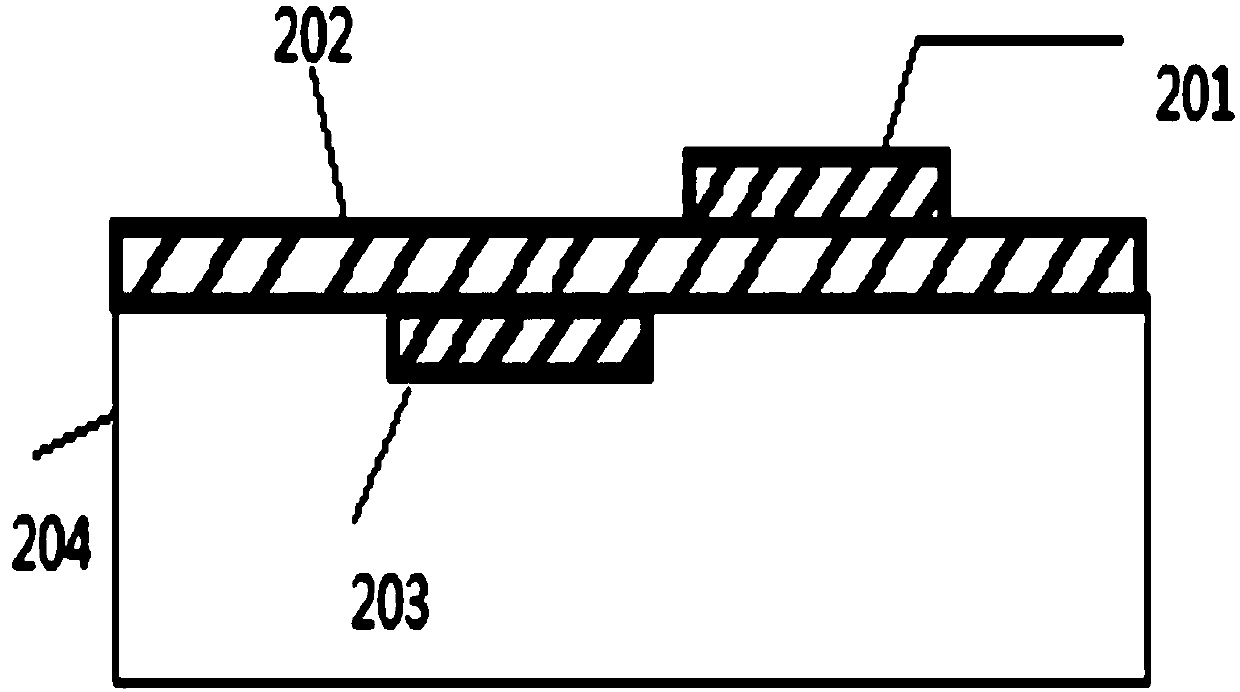

[0013] Such as figure 1 As shown, a dielectric barrier discharge plasma turbulent drag reduction device includes a bare electrode 201 , an insulating dielectric layer 202 , and a covering electrode 203 . In appearance, the exposed electrode 201 and the covered electrode 203 are rectangular in shape, and the insulating dielectric layer 202 is rectangular. The exposed electrode 201 and the covered electrode 203 are located on two surfaces of the insulating medium layer 202 respectively, and are staggered forward and backward.

[0014] In this example, the electrode flow lengths of the exposed electrode 201 and the covered electrode 203 are both 2.65 mm, and the size of the insulating medium layer is L×W×H=300×20×1.5 mm.

[0015] The device i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com