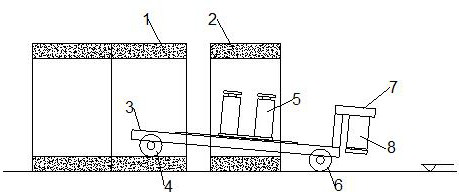

Single-bin prefabricated pipe gallery assembling vehicle and pipe gallery mounting method

A technology for assembling vehicles and pipe galleries, which can be applied to vehicle cleaning equipment, buildings, artificial islands, etc. It can solve the problems of long docking time and low installation and adjustment accuracy of single warehouse pipe galleries, so as to ensure balance, improve construction efficiency and construction quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

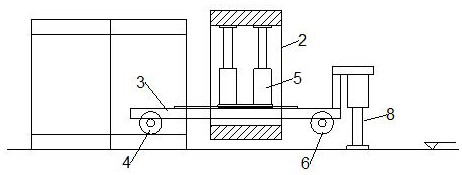

Examples

Embodiment 1

[0043] see Figure 4 , Image 6 , the mobile drive assembly includes a pulley 17 arranged on the lower surface of the sliding seat plate 13 , the pulley 17 is installed in the slide rail 14 , and the slide rail 14 is fixedly connected with the chassis 3 and arranged along the front and rear directions of the chassis 3 . In this embodiment, the mobile drive assembly also includes a traction motor 16 . The shaft end of the traction motor 16 is installed with a traction rope drum 19 , and the free end of the traction rope is connected to a traction hook 18 , which is fixed to the front end of the sliding seat plate 13 . The traction motor 16 is installed at the front end of the chassis 3 and may be located inside the second motor 10 . The sliding seat plate 13 can be a whole mounting plate, and the four jacking jacks 5 are all mounted on this whole mounting plate. One or two towing hooks 18 are arranged in front of the mounting plate. The sliding seat plate 13 can also be Fi...

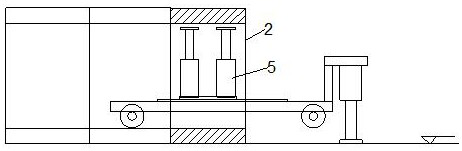

Embodiment 2

[0046] see Figure 7 to Figure 10 , another mobile drive assembly structure provided by the present invention, this embodiment is a combination of double push rods and sliding surfaces. The moving drive assembly includes a longitudinal push rod 21 mounted on the rear end of the chassis 3 and a transverse push rod 27 mounted on the right side of the chassis 3 . The longitudinal push rod 21 is parallel to the axis of the pipe gallery, and the transverse push rod 27 is perpendicular to the axis of the pipe gallery. The piston end of the longitudinal push rod 21 is connected with the rear side of the sliding seat plate 13, thereby pushing and pulling the sliding seat plate 13 to move it forward and backward; the piston end of the transverse push rod 27 is connected with the right side of the sliding seat plate 13, thereby pushing and pulling the sliding seat plate 13 to make it left and right move. The longitudinal push rod 21 and the transverse push rod 27 are respectively equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com