Light distribution type beam splitter, backlight module and method for improving light diffusion effect

A technology of backlight module and beam splitter, which is applied in the parts of lighting devices, identification devices, instruments, etc., can solve the problems of being difficult to meet the requirements of thinning and thinning, and the thickness of the backlight module is thick, so as to improve the divergence effect, uniform light, and extend the The effect of the illumination path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

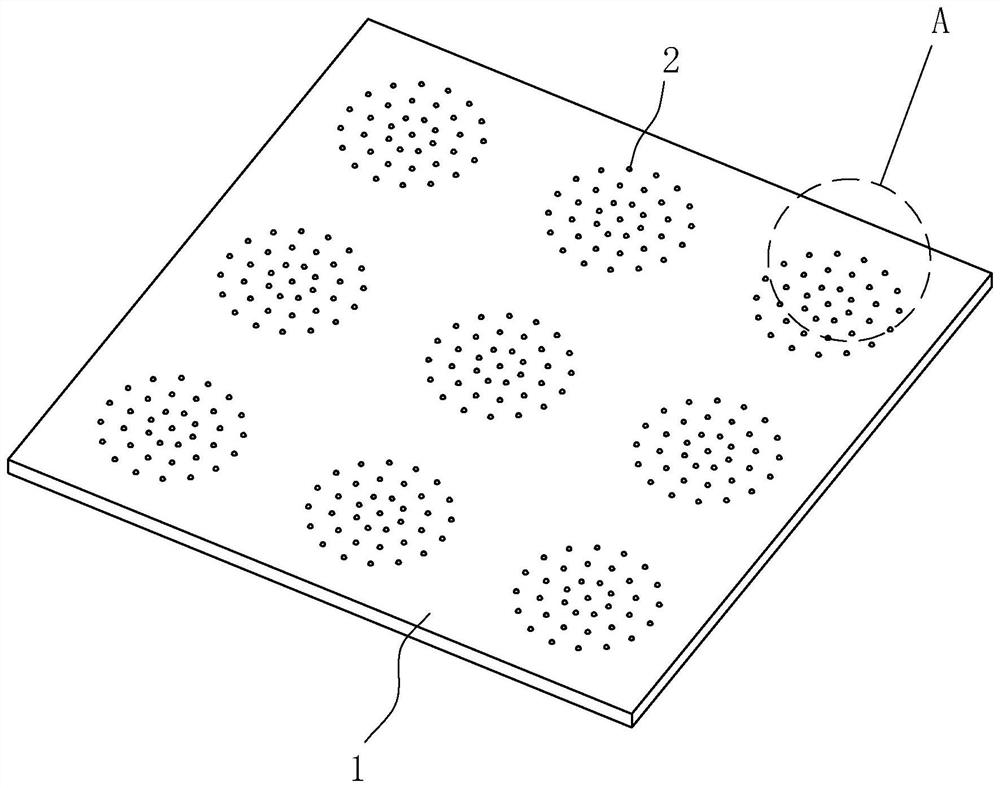

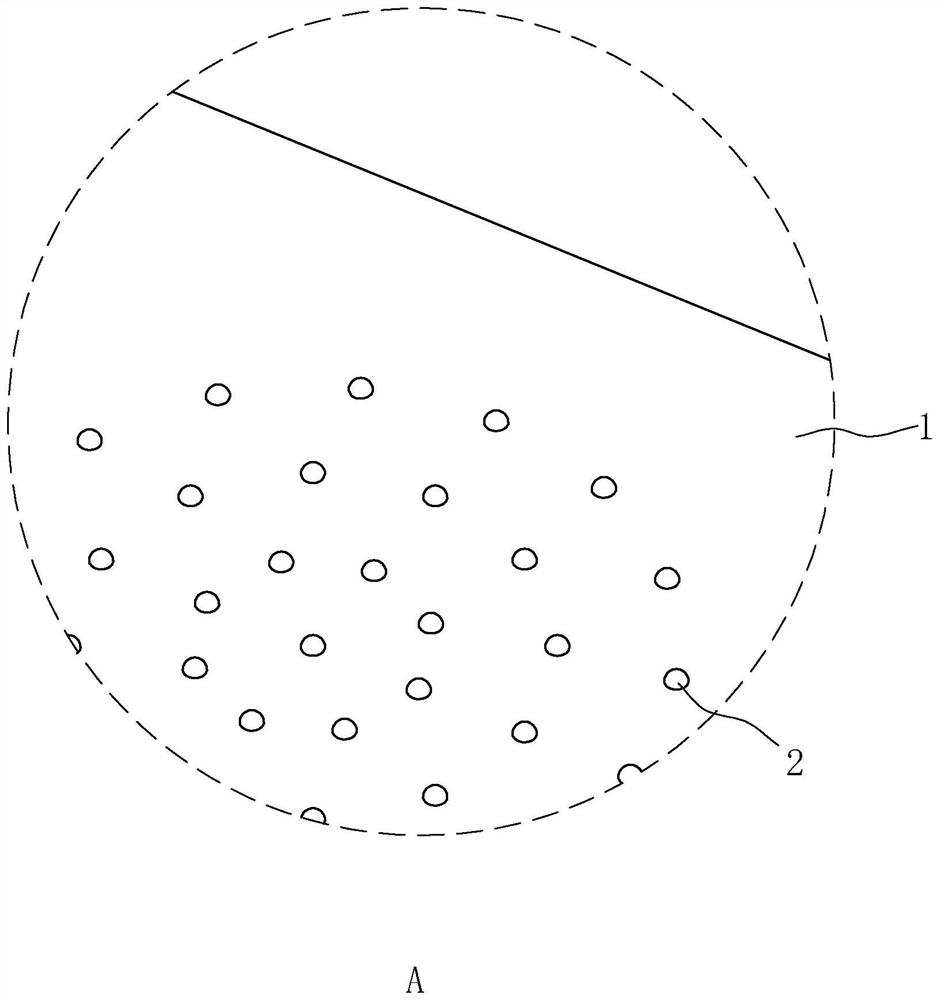

[0043] refer to figure 1 and figure 2 A light distribution type beam splitter plate comprises a plate body 1, a plurality of light reflection parts 2 are arranged on one side of the plate body 1, and the plurality of light reflection parts 2 are arranged at intervals. The light-reflecting portion 2 is formed by a plurality of bumps arranged at intervals, and the plurality of bumps are integrally formed on the surface of the plate body 1 . The reflective part 2 is formed with transparent reflective ink. After the light is irradiated on the beam splitter, the reflector 2 can reflect part of the light, and the other lights pass through the gap between the bumps and the gap between the reflectors 2, and form a surface light source under the atomization of the beam splitter. , and eliminates dark areas caused by bump reflections.

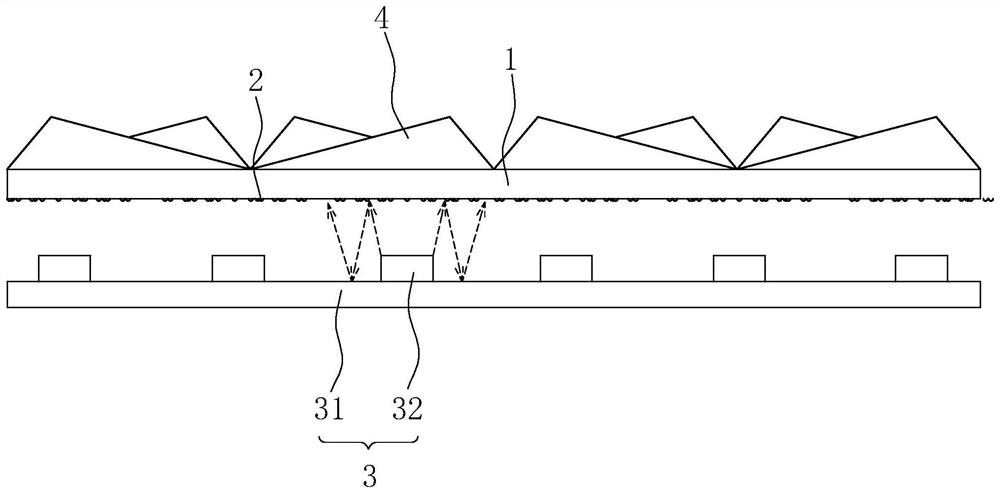

[0044] refer to figure 1 and image 3 , Embodiment 1 also discloses this kind of backlight module, including the above-mentioned light distributio...

Embodiment 2

[0056] refer to Figure 4 and Figure 5 The difference between Example 2 and Example 1 is that the reflective part 2 of the plate body 1 is formed by multiple depressions on the bottom surface of the plate body 1, and transparent reflective ink is sprayed in the depressions. By adopting the recessed structure, the light emitted by the lamp beads 32 is concentrated after the light is irradiated on the beam splitter, so that the light emitted by the lamp beads 32 has higher brightness and the backlight module emits higher brightness.

[0057] The reflective part 2 of the board body 1 can be formed by laser spotting, combined with reflective ink spraying.

Embodiment 3

[0059] refer to Image 6 The difference between Embodiment 3 and Embodiment 1 is that the light-reflecting portion 2 of the plate body 1 is formed by a plurality of light-reflecting points arranged at intervals. The reflective part 2 is formed by printing the transparent reflective ink on the surface of the plate body 1 . By printing the reflective ink on the surface of the board body 1 , the production and processing process is simpler, the setting efficiency of the reflective part 2 can be improved, and the production and processing efficiency of the board body 1 can be improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com