Rat and ant repelling cable and processing method thereof

A processing method and rodent repelling technology, applied in cables, power cables, communication cables, etc., can solve problems such as damage to the surface of optical cables, and achieve the effect of precise and efficient feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

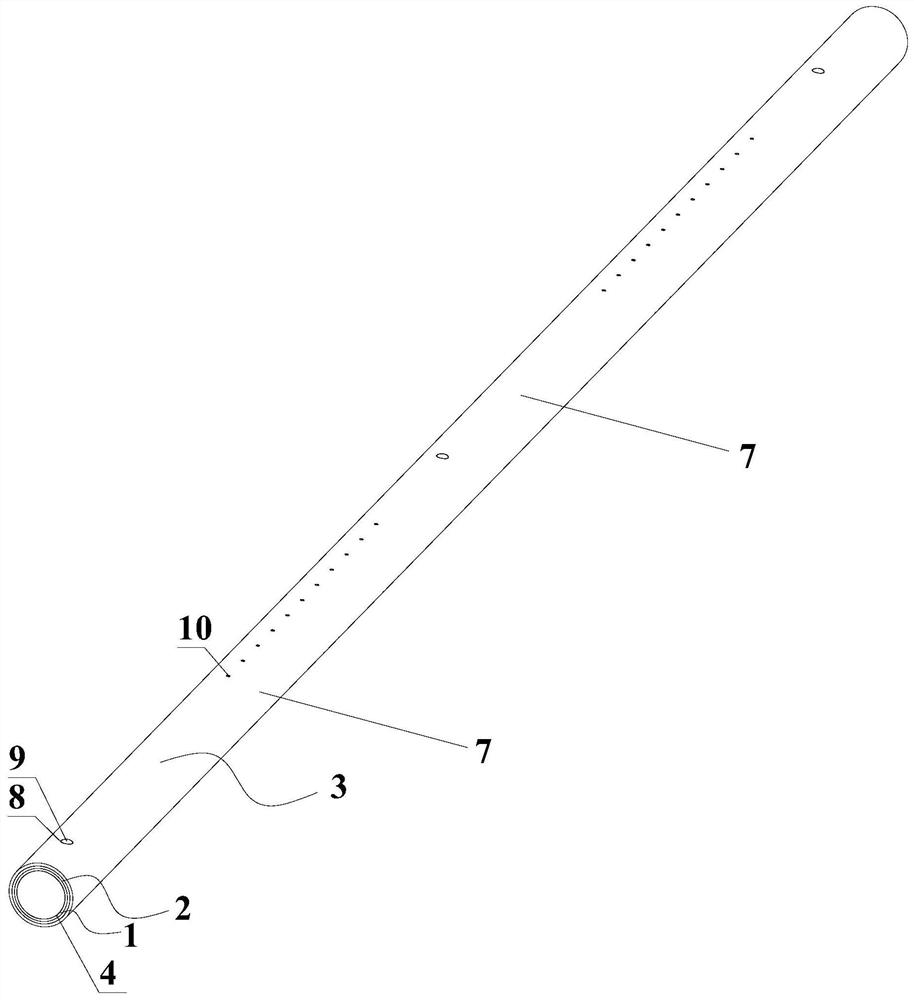

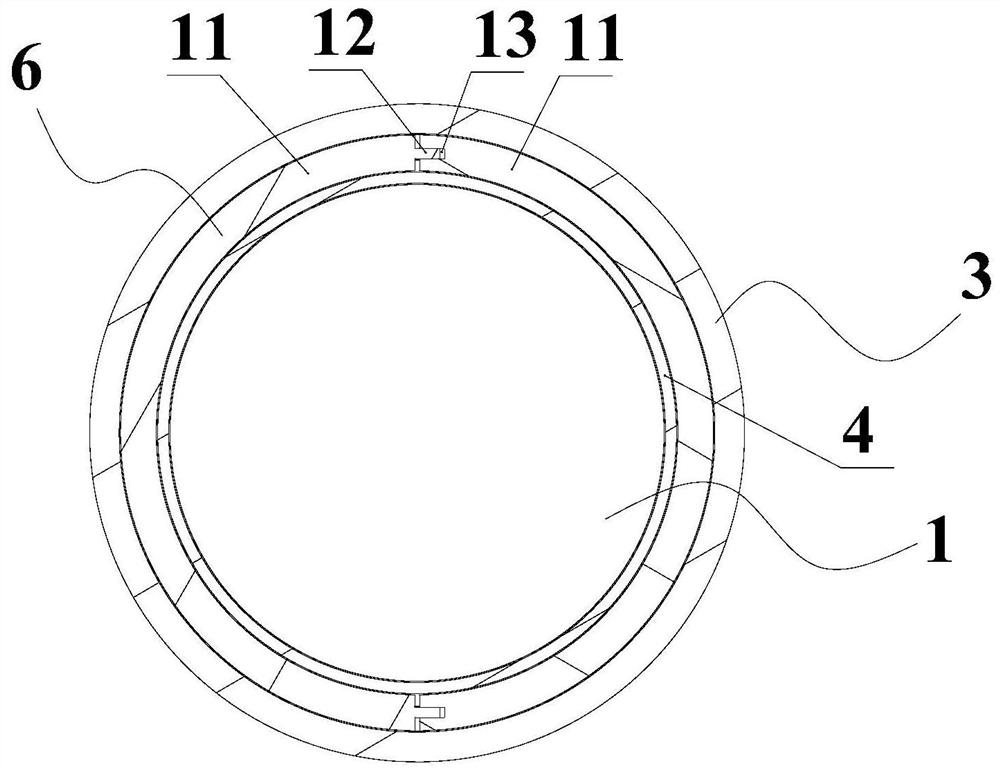

[0042] like Figures 1 to 7 As shown in the figure, a rodent repellent cable includes a cable body 1, a rodent repellent layer 2 and an outer sheath layer 3 sequentially arranged from the inside to the outside; the outer side of the cable body 1 has an inner sheath layer 4, The outer sidewall of the sleeve layer 4 has annular grooves 5 arranged at intervals; the rat repellent layer 2 includes a partition ring 6 installed on the annular clip groove 5, a foam material 16 located between two adjacent partition rings 6, and a The rodent and ant repellent agent in the foam material 16; the outer sheath layer 3 has a plurality of rodent and ant repellent sections 7, the rodent repellent section is located between the corresponding two partition rings 6, and the outer side wall of the rodent repellent section has feeding holes 8. Cover the plug 9 of the feeding hole 8 and the rat ant repelling groove 10 . The feeding hole 8 runs through the outer sheath layer 3 or is adjacent to the ...

Embodiment 2

[0057] like Figure 8 , 9 As shown in FIG. 10 , the difference between this embodiment and Embodiment 1 is that an elastic portion 14 is fixed on the outer side wall of the semi-circular ring 11 . The provision of the elastic portion 14 can prevent the foamed materials 16 at adjacent ends from communicating with each other as much as possible when the foamed material 16 is extruded. Specifically, when the foamed material 16 is extruded, the outer diameter of the foamed material 16 is smaller than that of the elastic portion. 14 outside diameter.

[0058] In this embodiment, the cross section of the elastic portion 14 is triangular.

[0059] In this embodiment, the outer edge of one end surface of the semi-circular ring 11 has a chamfer 15 . Setting the chamfer 15 facilitates the positioning of the extrusion tooling and the isolation ring, and enables the isolation ring to pass through the extrusion tooling better and more accurately.

[0060] This embodiment also discloses...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com