Auxiliary blanking mechanism of circular winding needle blanking clamping and pressing block

An auxiliary blanking and rolling needle technology, which is applied in the direction of electrical components, electrolyte battery manufacturing, electrochemical generators, etc., can solve problems such as rolling, unbalanced force on cells, and affecting cell processing, and achieve high-efficiency blanking , stable operation and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

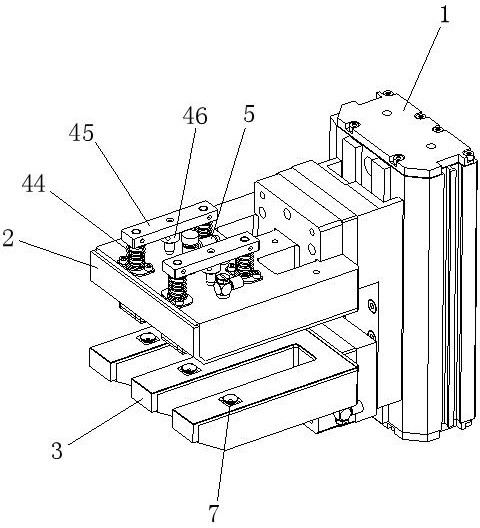

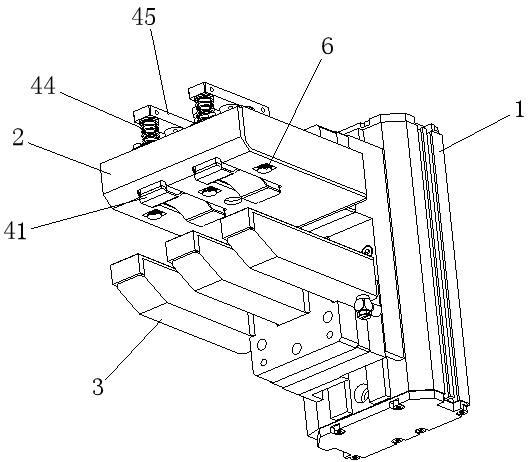

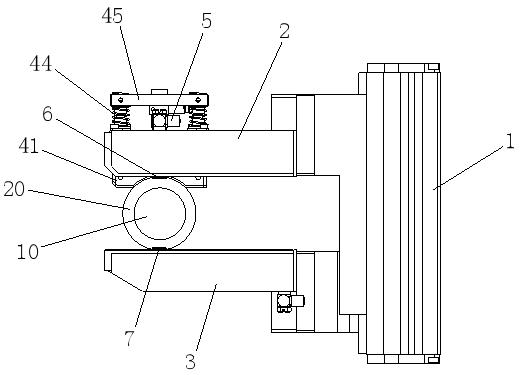

[0028] In order to solve the problem of blanking after the round needle is wound and to solve the problem of wrinkling and sagging of the inner ring of the elliptical needle, please refer to Figures 1~4 , this embodiment provides a circular rolling needle blanking clamp press block auxiliary blanking mechanism for circular rolling needle auxiliary blanking, which includes a clamping jaw drive device 1, an upper clamping jaw 2 and a lower clamping jaw 3. The clamping jaws One side of the driving device 1 is provided with a vertical guide rail, and the upper jaw 2 and the lower jaw 3 are arranged to move up and down on the vertical guide rail, and are driven to move up and down by the jaw driving device 1. The clamping device is driven by the clamping jaw driving device 1 and the lower clamping jaw 3 to clamp both sides of the battery cell 20, so that the round needle 10 can be pulled out from the battery core 20.

[0029] In this embodiment, the clamping jaw driving device 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com