Automatic conveying type paint spraying device for furniture processing

A technology for automatic conveying and furniture, applied in the direction of injection device, liquid injection device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

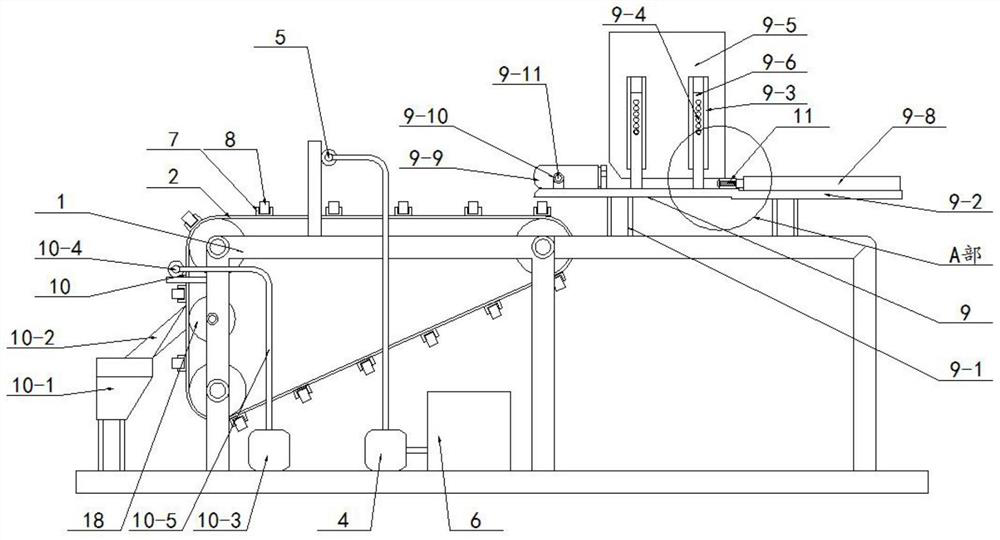

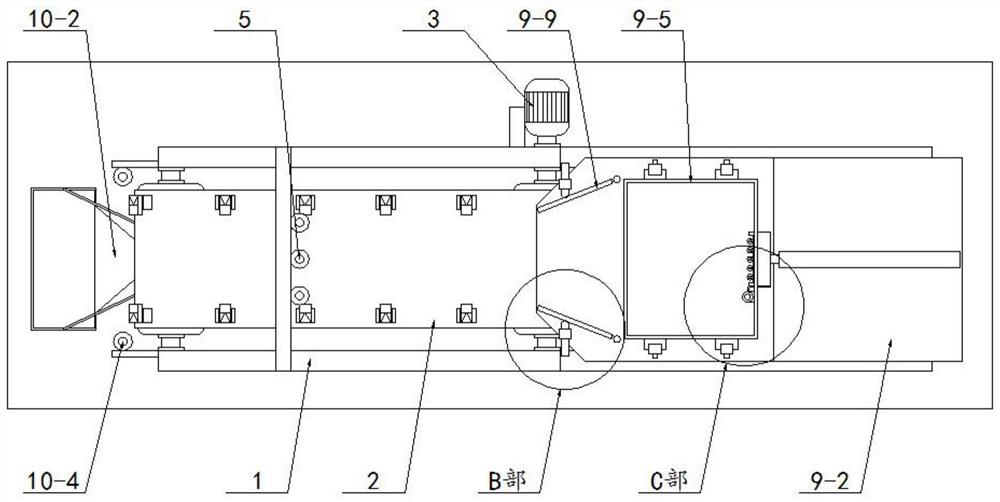

[0048] like figure 1 , 2As shown, this embodiment includes a frame 1, a conveyor belt 2, a drive motor 3, a water pump 4, a nozzle 5, and a storage tank 6, wherein the conveyor belt 2 is screwed on the frame 1 through bearings, and the drive motor 3 is fixed to the machine through screws. On the frame 1, and the drive motor 3 and the rear end of the right shaft of the conveyor belt 2 are driven and arranged, the nozzle 5, the water pump 4, and the storage tank 6 are all fixed on the frame 1 by screws, and the nozzle 5 is arranged above the conveyor belt 2, The nozzle 5 is connected with the discharge end of the water pump 4 through a pipeline, and the feed end of the water pump 4 and the discharge end of the storage tank 6 are connected through a pipeline. It also includes:

[0049] Slots 7, described slots 7 are several, and the front and rear equal numbers are divided into two groups to set, and the front and rear two groups of slots 7 are symmetrically fixed on the front a...

Embodiment 2

[0055] like figure 1 , 2 As shown, on the basis of the above-mentioned Embodiment 1, the loading positioning member 9 includes:

[0056] A support frame 9-1, the support frame 9-1 is fixed on the frame 1 by screws, and the support frame 9-1 is arranged on the right side of the conveyor belt 2;

[0057] The bottom plate 9-2, the bottom plate 9-2 is fixed on the support frame 9-1 by screws, and the bottom plate 9-2 is arranged above the conveyor belt 2;

[0058] There are several guide rails 9-3, and the front and rear are symmetrically fixed on the upper surface of the base plate 9-2 by screws. The guide rails 9-3 are equally spaced from top to bottom. 9-4 positioning holes;

[0059] The feeding box 9-5, the feeding box 9-5 is arranged between the guide rails 9-3 on the front and rear sides;

[0060] Guide groove 9-6, the guide groove 9-6 is fixed on the outer side wall of the feeding box 9-5 by screws, and the guide rail 9-3 is movably inserted in the guide groove 9-6;

...

Embodiment 3

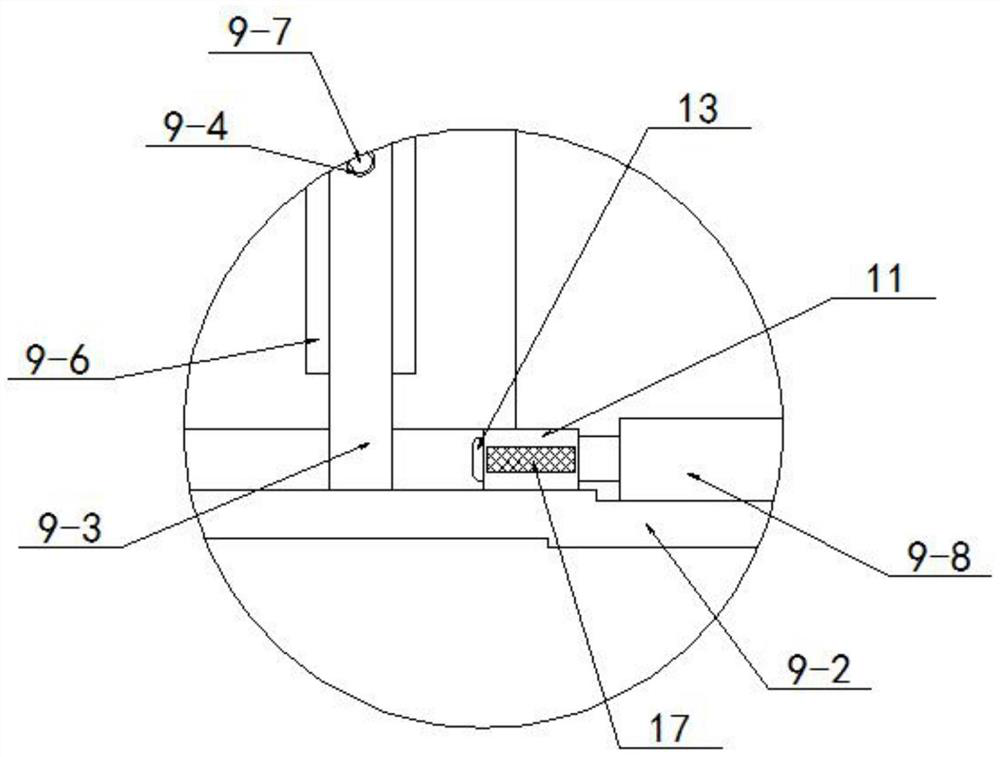

[0068] like figure 1 , 2 , 3 and 5, on the basis of the above-mentioned Embodiment 2, the output end of the feeding electric push rod 9-8 is fixed with a pushing plate 11 by screws, and the pushing plate 11 is arranged on the feeding box 9 Below -5, and the ejector plate 11 is movably abutted on the upper surface of the bottom plate 9-2, an installation cavity 12 is opened on the left side wall of the ejector plate 11, and a support wheel 13 is arranged in the installation cavity 12, and is arranged with the support wheel 13. The ejector plates 11 are rotated through the rotating shaft, and the left end of the support wheel 13 extends to the left side of the installation cavity 12;

[0069] With the above design scheme, the feeding electric push rod 9-8 pushes the pusher plate 11 against the right side of the raw material plate, and then the support wheel 13 pushes the plate against the plate, and then pushes the plate to the left, and the plate passes through the guide plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com