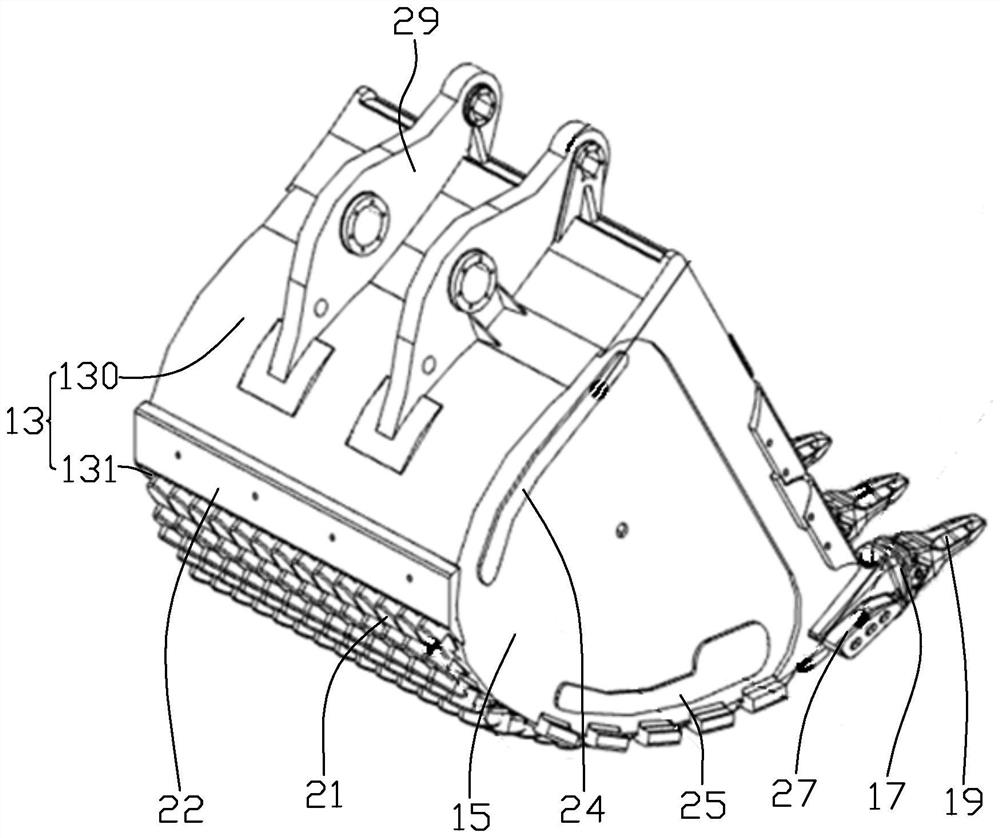

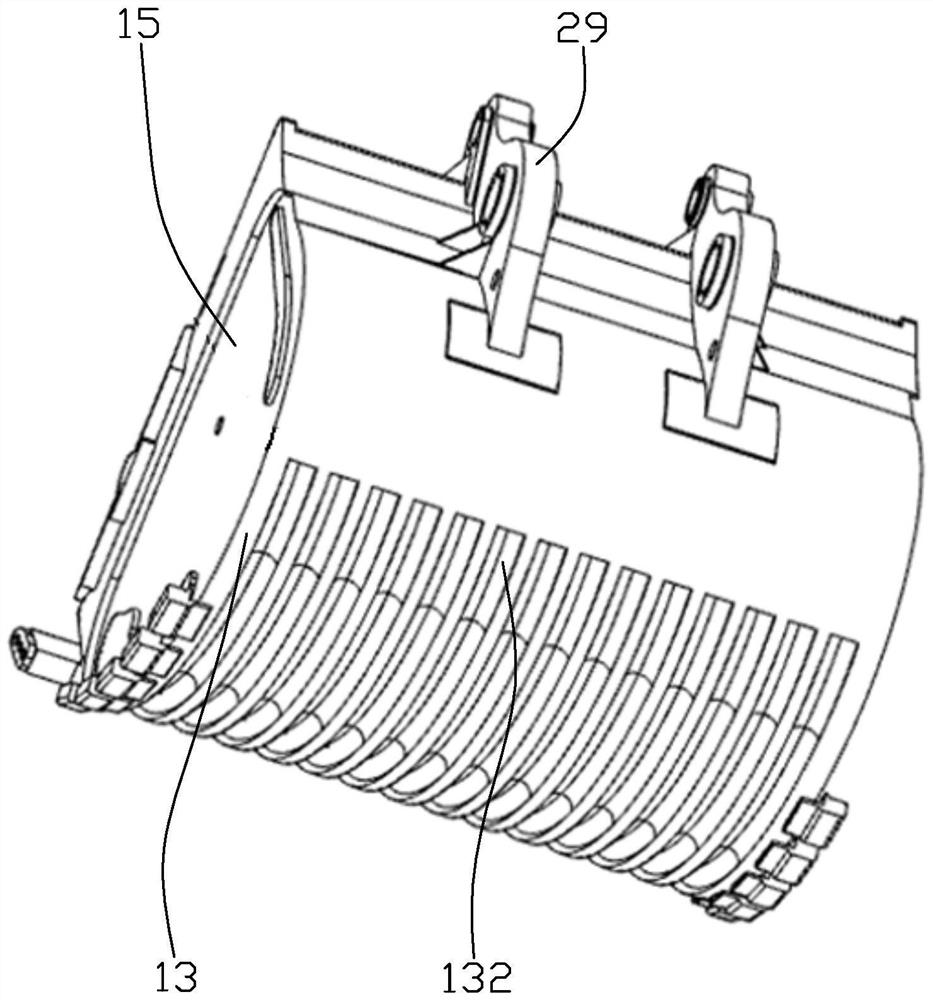

Bucket and excavator

A bucket and bucket tooth technology, applied in the field of basic construction equipment, can solve the problems that the anti-wear performance is difficult to be greatly improved, the number and thickness of wear-resistant plates are increased, and the service life is not significantly improved, so as to achieve a good effect of soil removal and resistance reduction , reduce friction, reduce the effect of soil contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

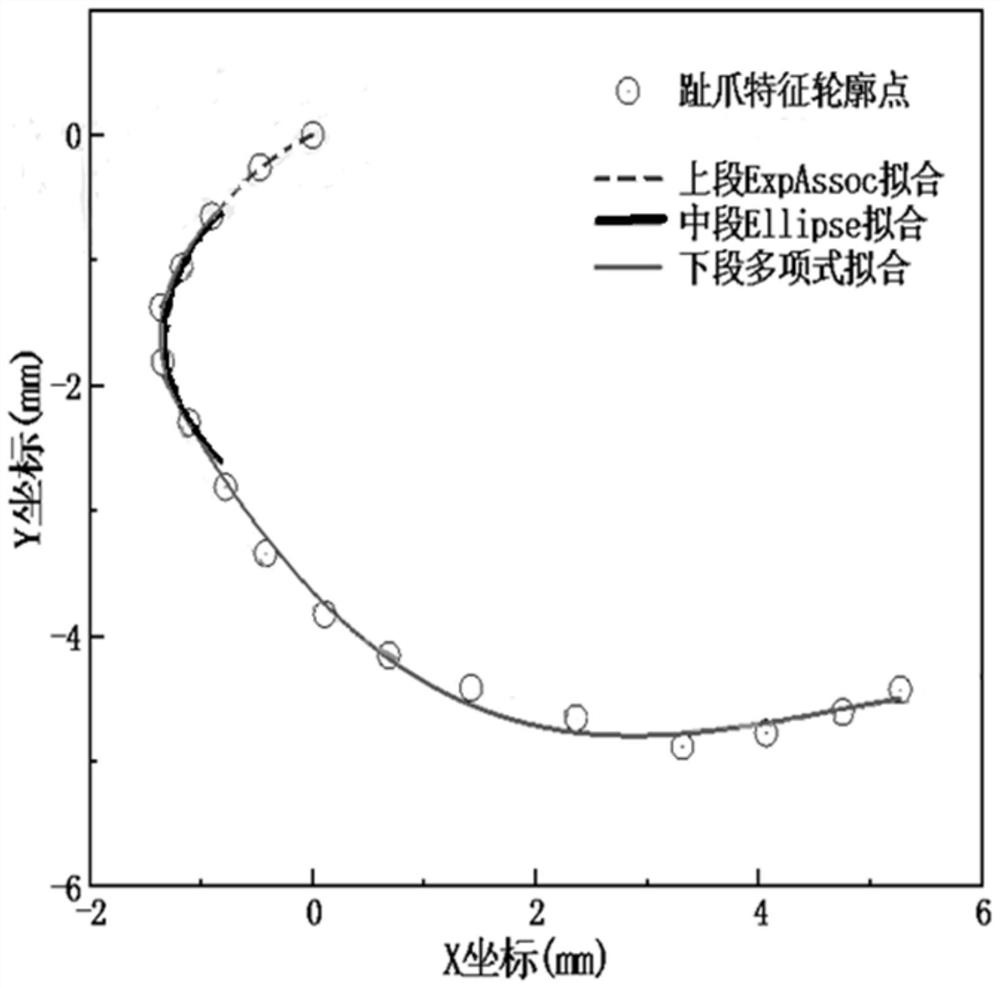

Embodiment Construction

[0033] The foregoing and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of the preferred embodiments with reference to the drawings. Through the description of the specific embodiments, it is possible to have a more in-depth and specific understanding of the technical means and effects adopted by the present invention to achieve the predetermined purpose. However, the accompanying drawings are only for reference and description, not for the present invention. limit.

[0034] As used herein, the terms "first", "second", "third", "fourth", "fifth", etc. (if present) are used to distinguish similar objects and are not necessarily used to describe a particular order or sequence.

[0035] In this document, references to "upper," "lower," "left," "right," "front," "rear," "top," "bottom," etc. (if any) are used in the accompanying drawings. The positions of the structures in the drawings and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com