Adjusting mechanism of drafting assembly of spinning frame

An adjustment mechanism and spinning frame technology, applied in spinning machines, drafting equipment, textiles and papermaking, etc., can solve the problems of time-consuming and laborious installation and operation, structure without adjustment, unfavorable use of spinning frames, etc., to achieve split The effect of simple structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

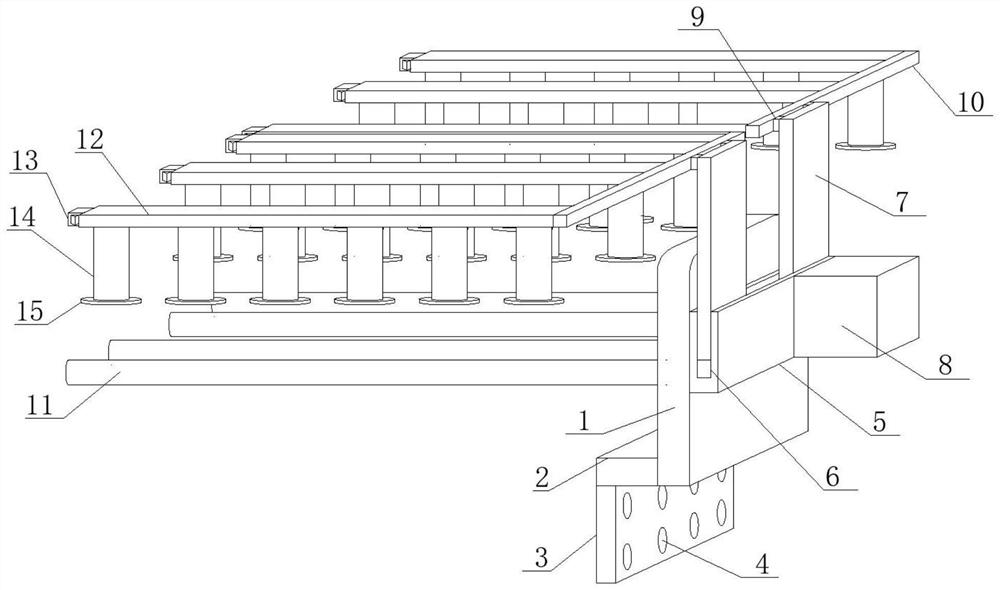

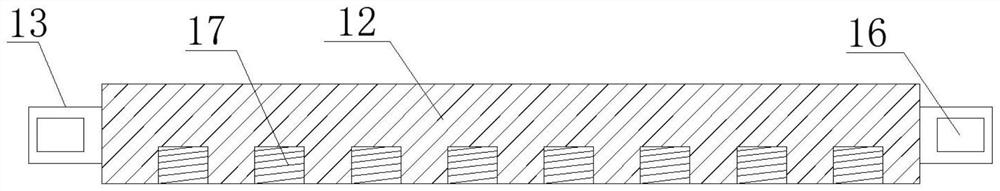

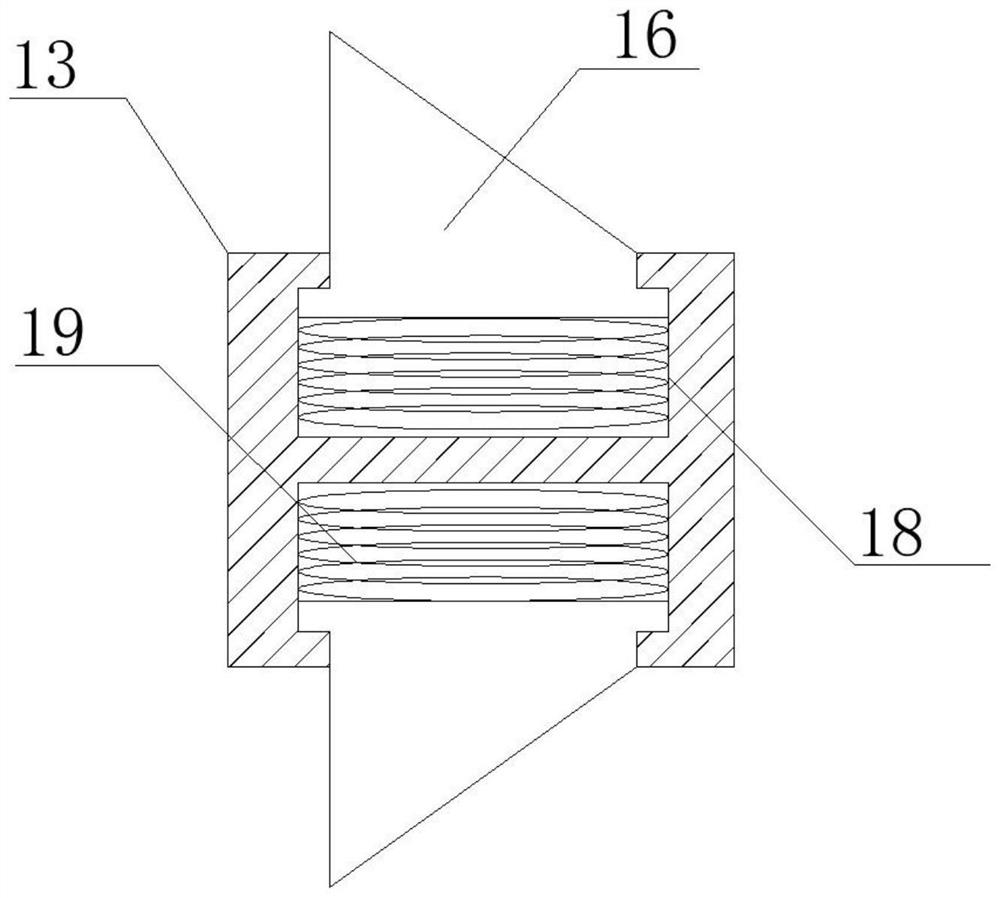

[0027] see Figure 1-2, In the embodiment of the present invention, an adjustment mechanism for a drafting assembly of a spinning frame includes a supporting side plate 1, the side of the supporting side plate 1 is vertically welded with a connecting cross plate 2, and the bottom surface of the connecting cross plate 2 is vertically downward welded with a Fixed connecting plate 3, fixed through holes 4 are evenly opened on the side of the fixed connecting plate 3, a side fixing block 5 is welded on one side of the supporting side plate 1, and one side of the connecting horizontal plate 2 is vertically fixed on the supporting side plate. The side of 1 is close to the bottom surface, the top of the fixed connecting plate 3 is vertically fixed at the position of the bottom surface of the connecting horizontal plate 2 away from the side of the supporting side plate 1, the number of fixed through holes 4 is multiple, and multiple fixed The through holes 4 are all open through the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com