Press-fit equipment with good press-fit product flatness

A technology of lamination equipment and flatness, which is applied in the direction of mechanical equipment, connecting components, manufacturing tools, etc., and can solve problems affecting the flatness of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to further understand the features, technical means, and specific goals and functions of the present invention, the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

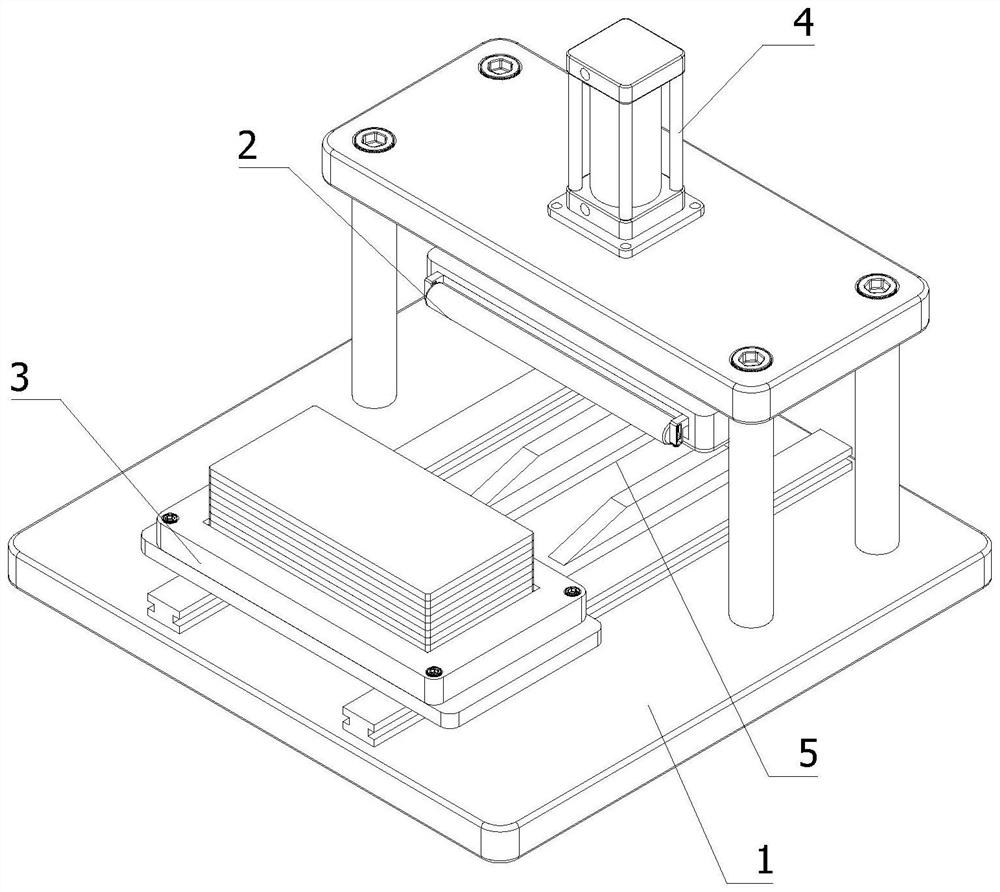

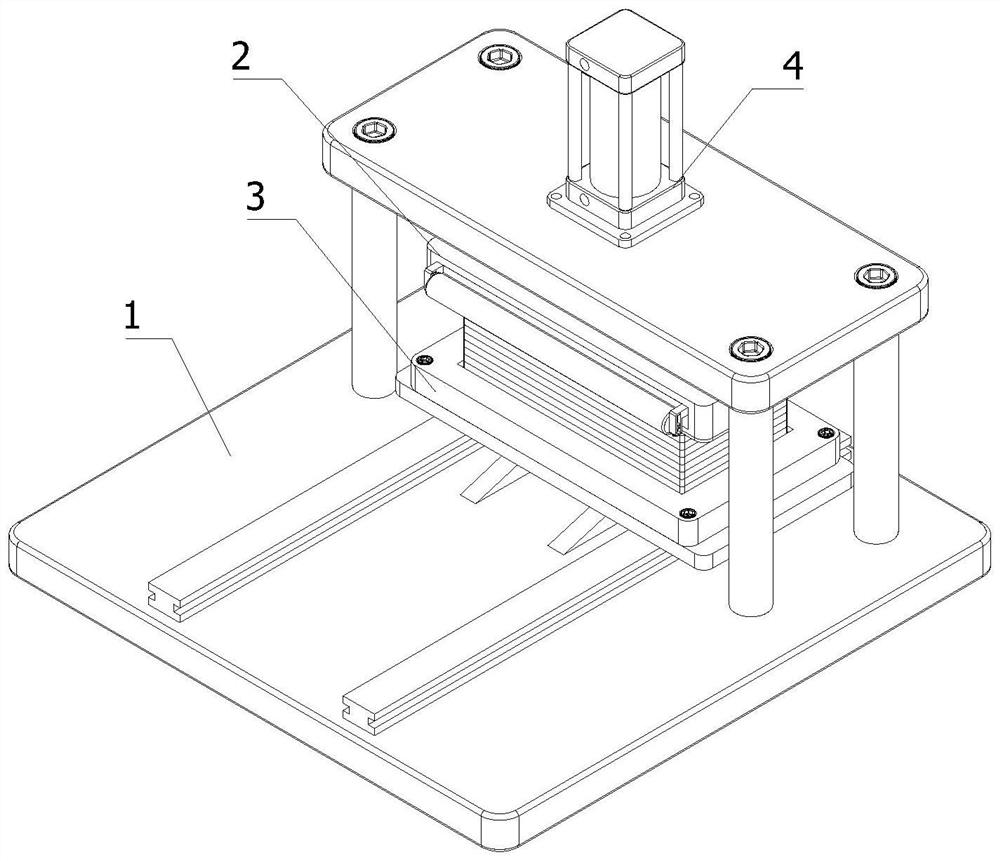

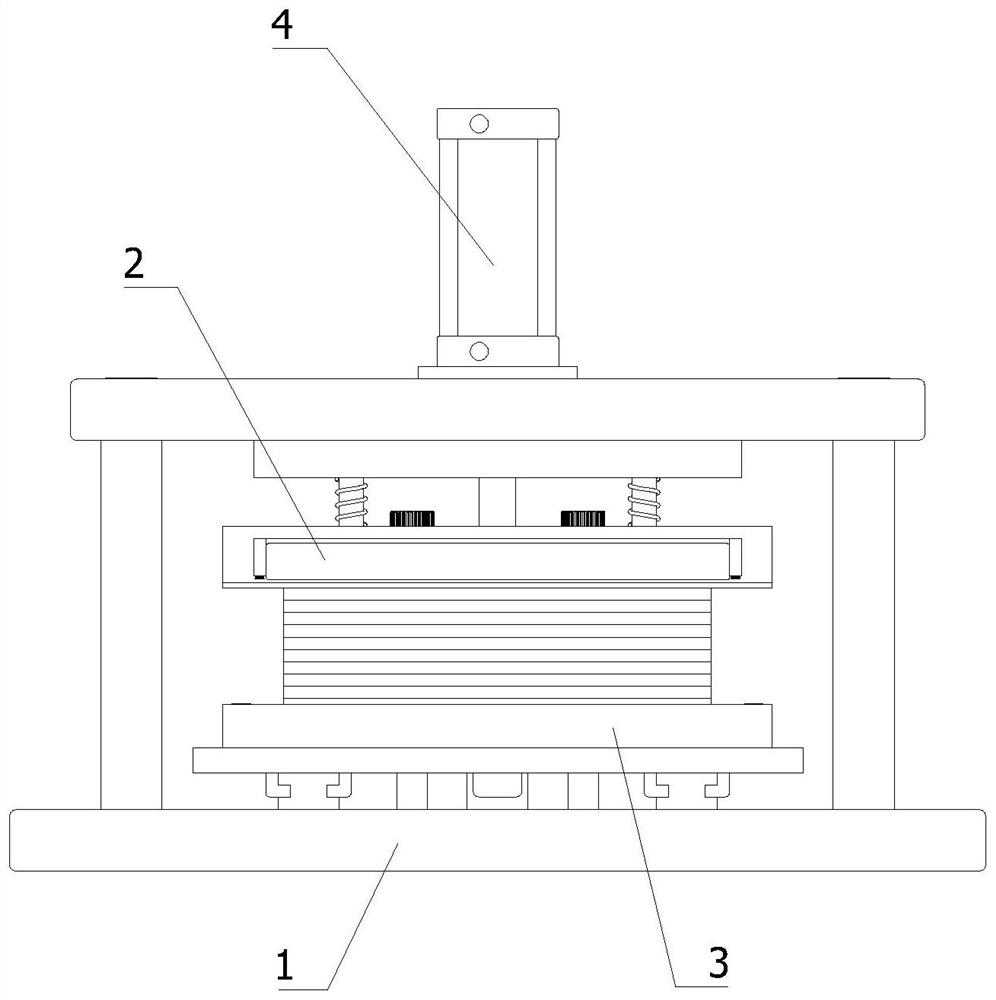

[0044] like Figure 1 to Figure 10 As shown, this application provides:

[0045]A lamination equipment with good flatness of lamination products, comprising a base 1, a first template 2, a second template 3, a first moving assembly 4 and a second moving assembly 5, the first template 2 includes a first flat plate 2a, a second template Two flat plates 2b, a first spring 2c, a second spring 2d and a roller 2e. A guide rod 2a1 is provided on the side of the first flat plate 2a close to the first moving assembly 4. The axis of the guide rod 2a1 is related to the moving direction of the first moving assembly 4. Keeping parallel, the first spring 2c is sleeved on the guide rod 2a1, and the side wall of the first plate 2a i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com