Device and method for testing service life of knuckle bearing by using air pressure loading

A technology of life test device and joint bearing, which is applied in the direction of mechanical bearing testing, measuring device, testing of mechanical parts, etc., can solve the problems of complex structure, large force value fluctuation, unfavorable low air pressure environment, etc., and achieve a small range of pressure changes , Loading force fluctuation is small, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

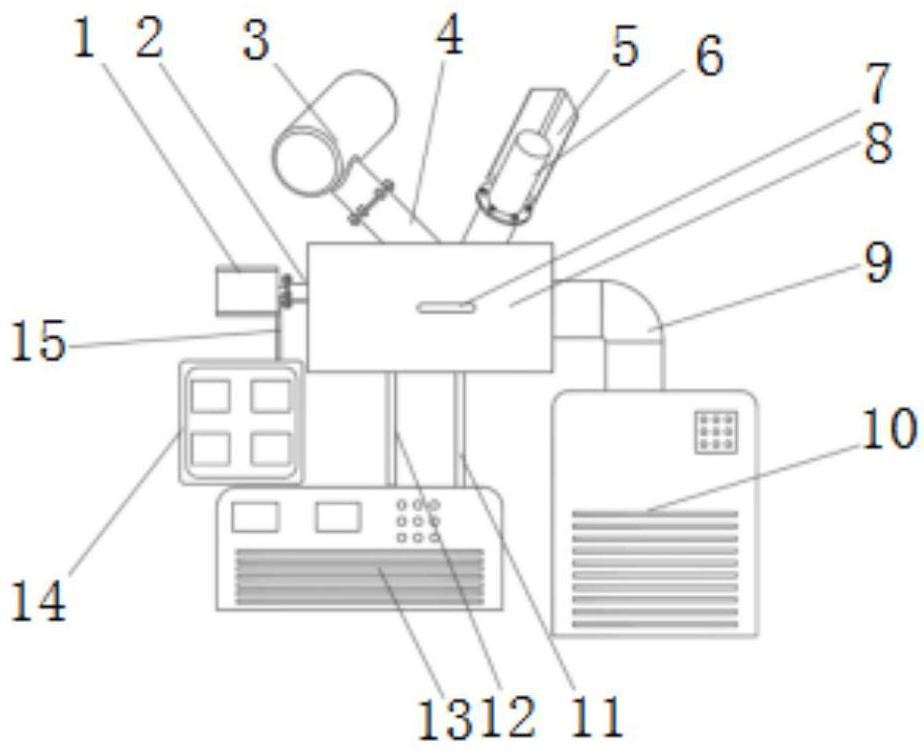

[0038] This embodiment provides a life test device for a spherical plain bearing using air pressure loading, especially for the life test of a film type self-lubricating radial spherical plain bearing, such as figure 1 As shown, it includes a space environment simulation part, a test part and a control part. The space environment simulation part is used to simulate the space environment during the test process, such as simulating high and low temperature, atomic oxygen irradiation, ultraviolet irradiation, proton irradiation, etc.; the control part It is mainly composed of a control device 14 and a control line 15, which are used for the operating conditions of the test device, collecting the signals of the sensors and displaying the changing law of the data.

[0039] The specific structure of the life test device is as follows:

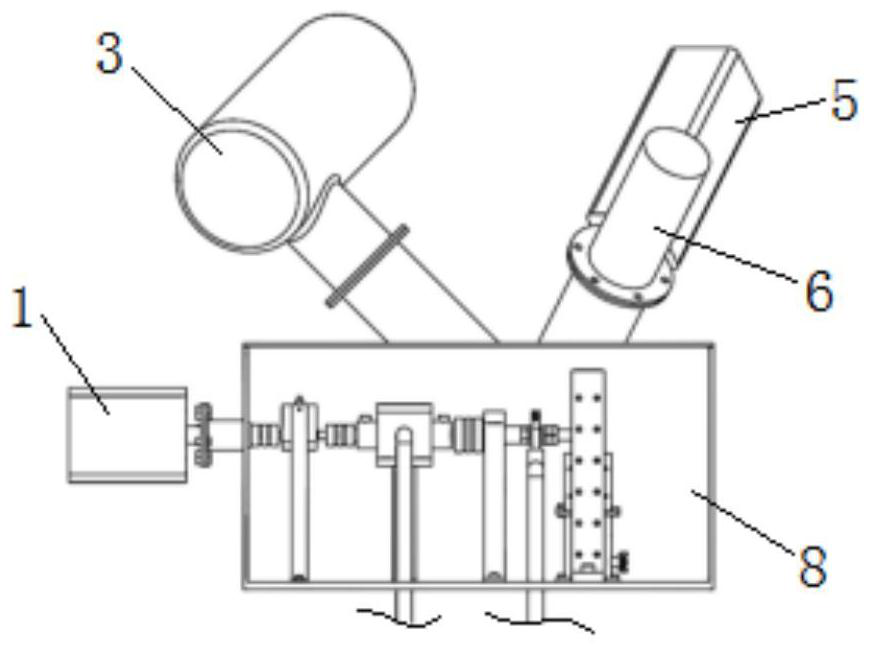

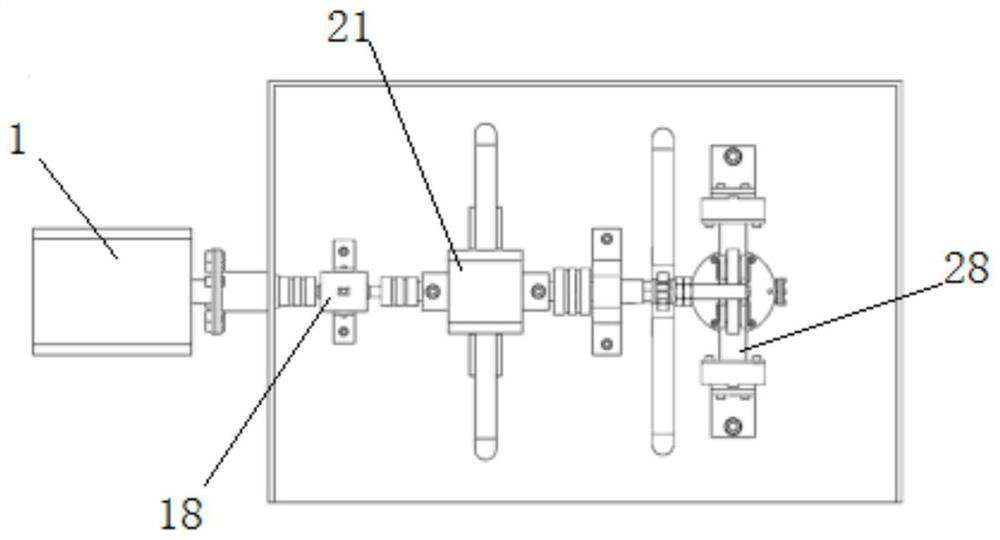

[0040] like figure 1 and figure 2 As shown, the space environment simulation part includes a vacuum chamber 8, a vacuum device 10, a temperature ...

Embodiment 2

[0063] This embodiment provides a life test method for a spherical plain bearing using air pressure loading. Using the test device described in the first embodiment, the inner diameter of the film type self-lubricating radial spherical plain bearing is 10 mm, the width of the outer ring is 8 mm, and the cylinder is filled with 1 standard atmospheric pressure gas, the inner diameter of the cylinder is 80mm, the test vacuum condition is 1×10-4Pa, and the loading load is about 502.4N, as an example to describe in detail, including the following steps:

[0064] Step 1: According to the required load size, according to the formula F=(P 1 -P 2 )×S (F is the load, P 1 is the pressure inside the cylinder, P 2 For the pressure of the vacuum chamber, S is the area of the cylinder) to obtain the required diameter of the cylinder.

[0065] Step 2: Install the cylinder in the vacuum chamber;

[0066] Step 3: Install the film type self-lubricating radial spherical plain bearing at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com