Portable grinding machine having improved vibration isolation mechanism

A sand mill and orbital motion technology, applied in the field of sand mills, can solve the problems of wear and tear of the claws and shorten the service life of the elastic claws.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

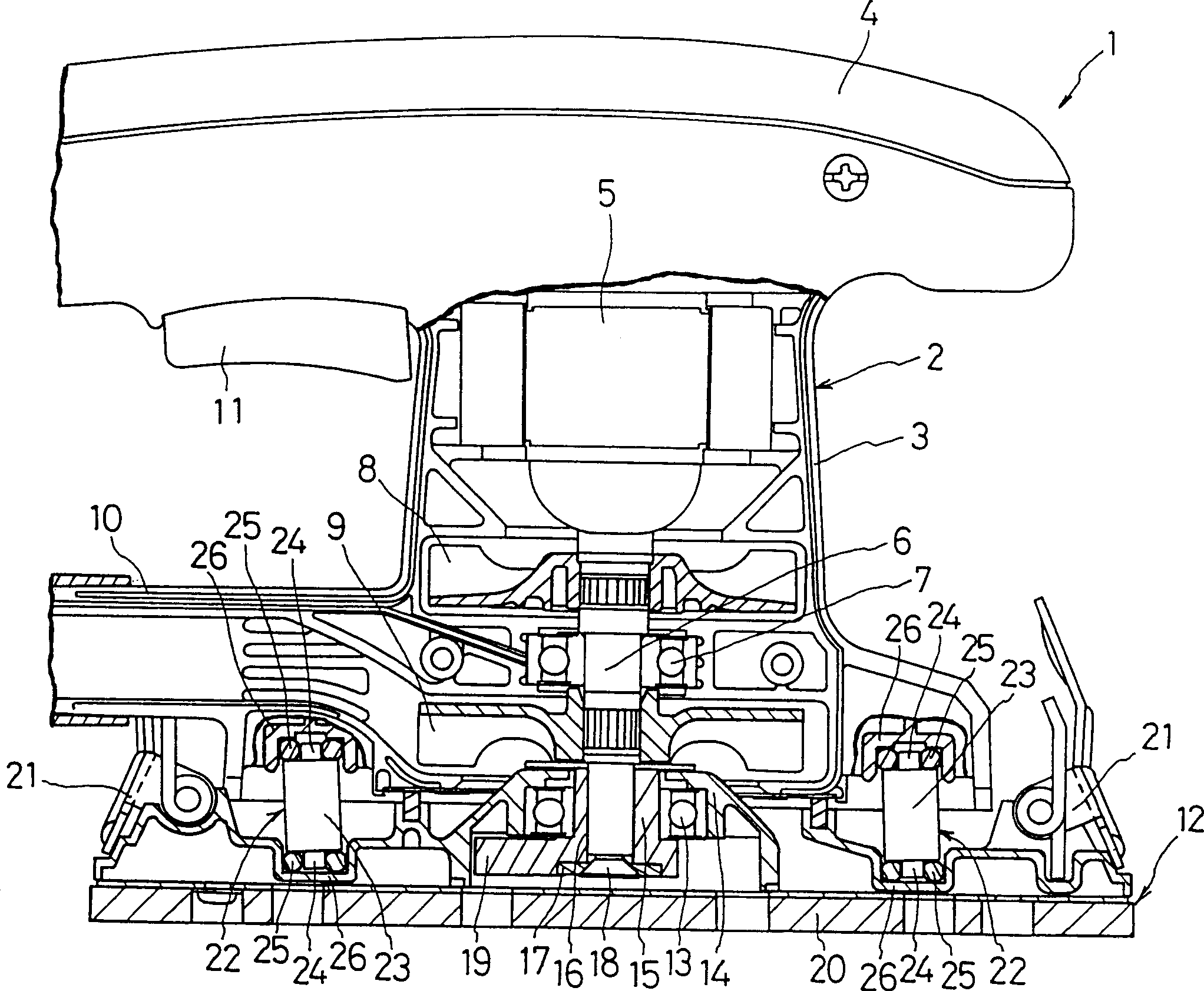

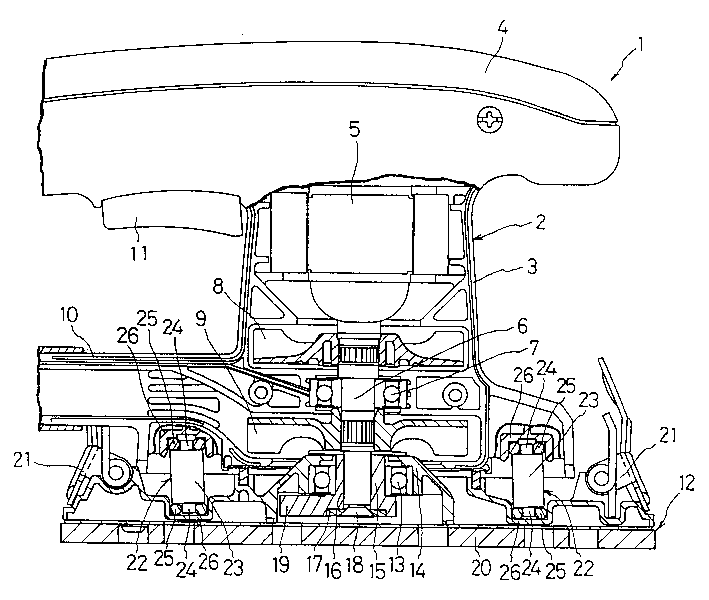

[0019] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

[0020] figure 1 It is a sectional view of the polishing sand mill 1 of the present invention. The polishing sand mill 1 includes a main body 2 and a base plate 12 disposed thereunder. The main body 2 comprises a pair of vertically split half shells 3 and 4, the shells contain a downwardly mounted motor 5, the output shaft 6 of which is supported by a ball bearing 7. The output shaft 6 of the motor 5 protrudes downwards into the base plate 12 from the bottom of the main body 2 . The cooling fan 8 is mounted on the output shaft 6 and above the ball bearing 7 to supply cooling air to the motor 5, and the dust suction fan 9 is also mounted on the output shaft 6 and below the ball bearing 7 to suck the main body 2 dust particles and other debris below, and send these waste materials to the dust suction hole 10 located on the left side of the main body 2 (a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com