Method for fitting zero phase sequence converter in leakage circuit breaker

A zero-phase-sequence converter and leakage circuit breaker technology, applied in circuits, inductors, electrical components, etc., can solve problems such as product quality differences, increased costs, and unstable relative positions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] based on the following Figure 1-Figure 4 The illustrated examples illustrate embodiments of the invention.

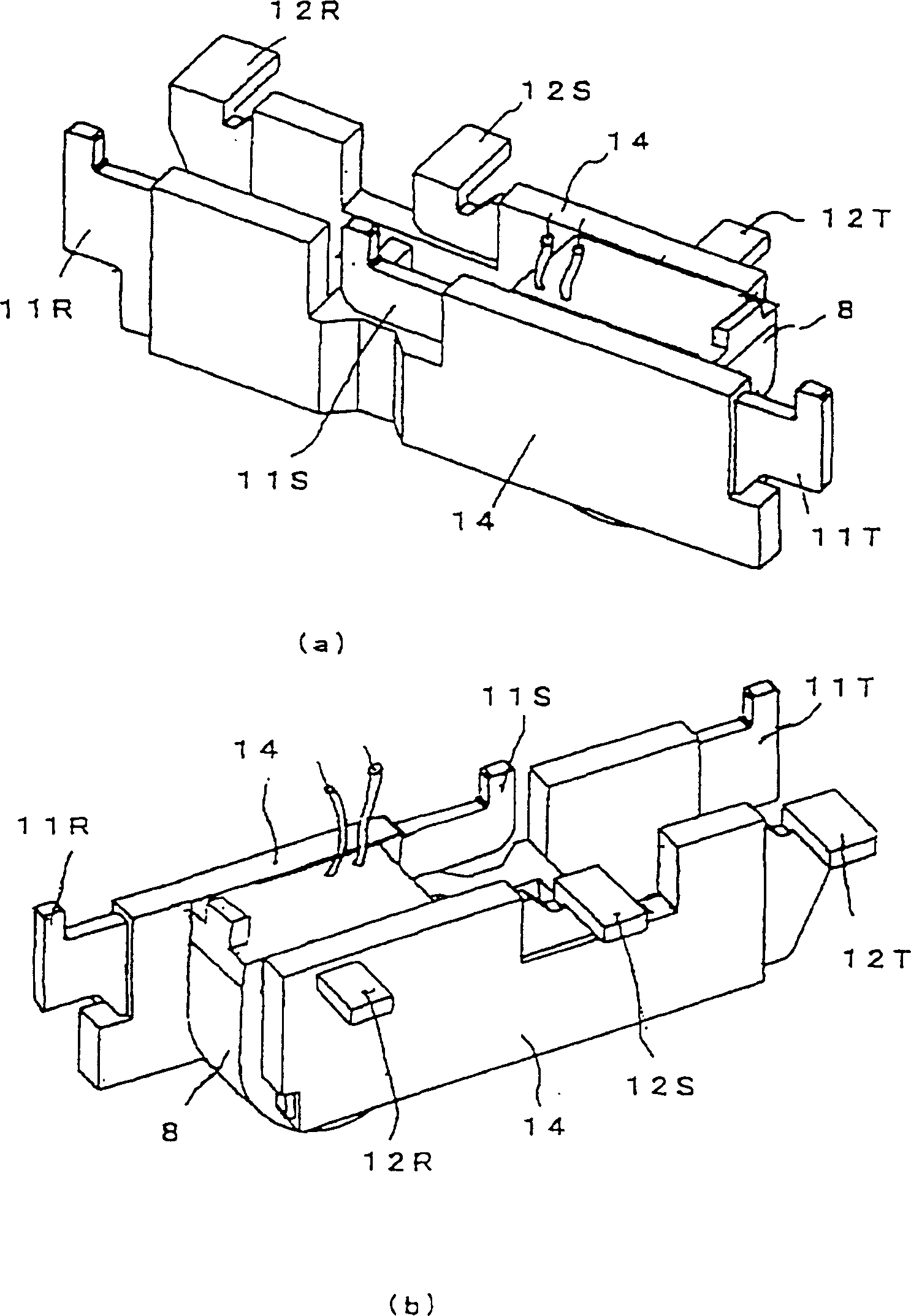

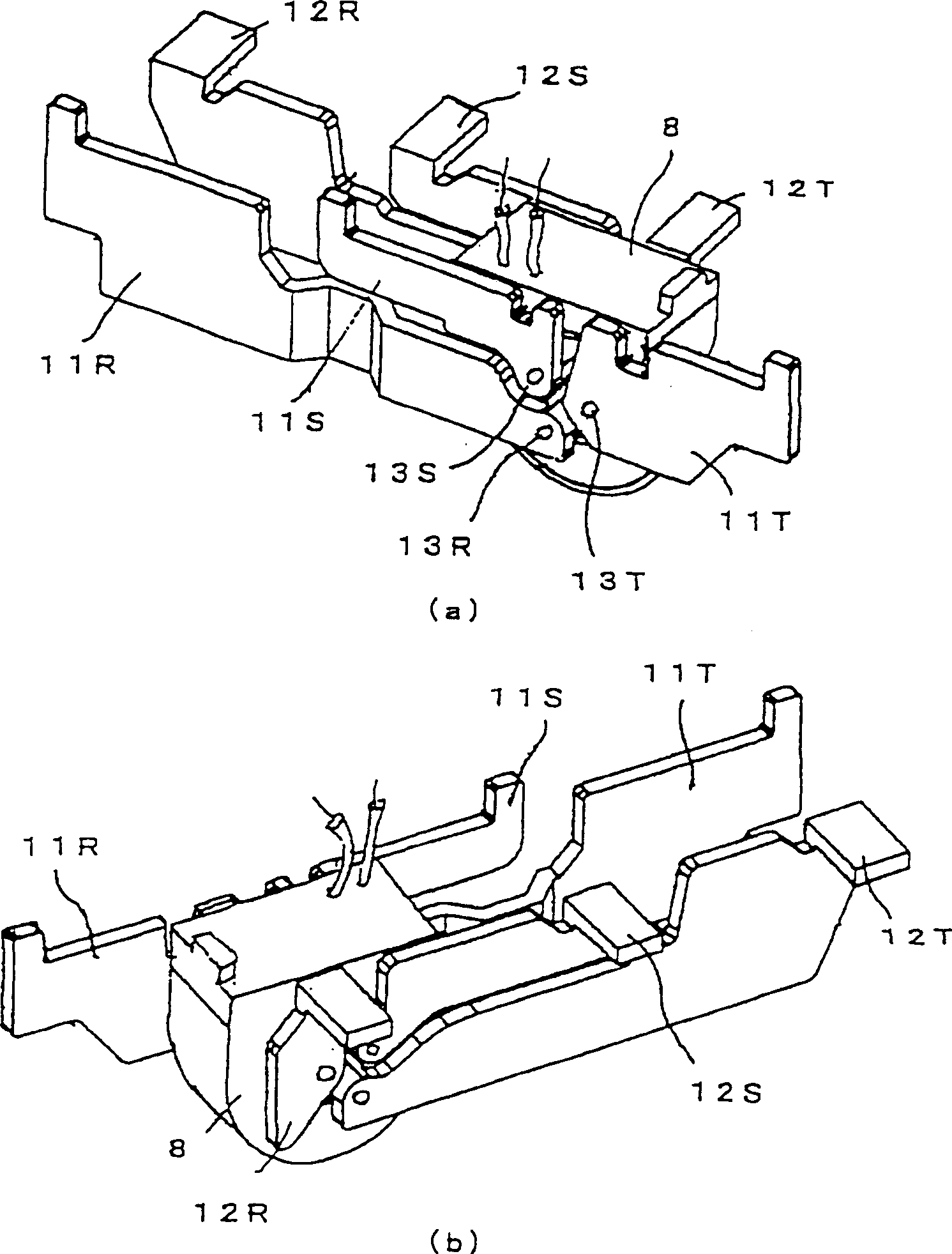

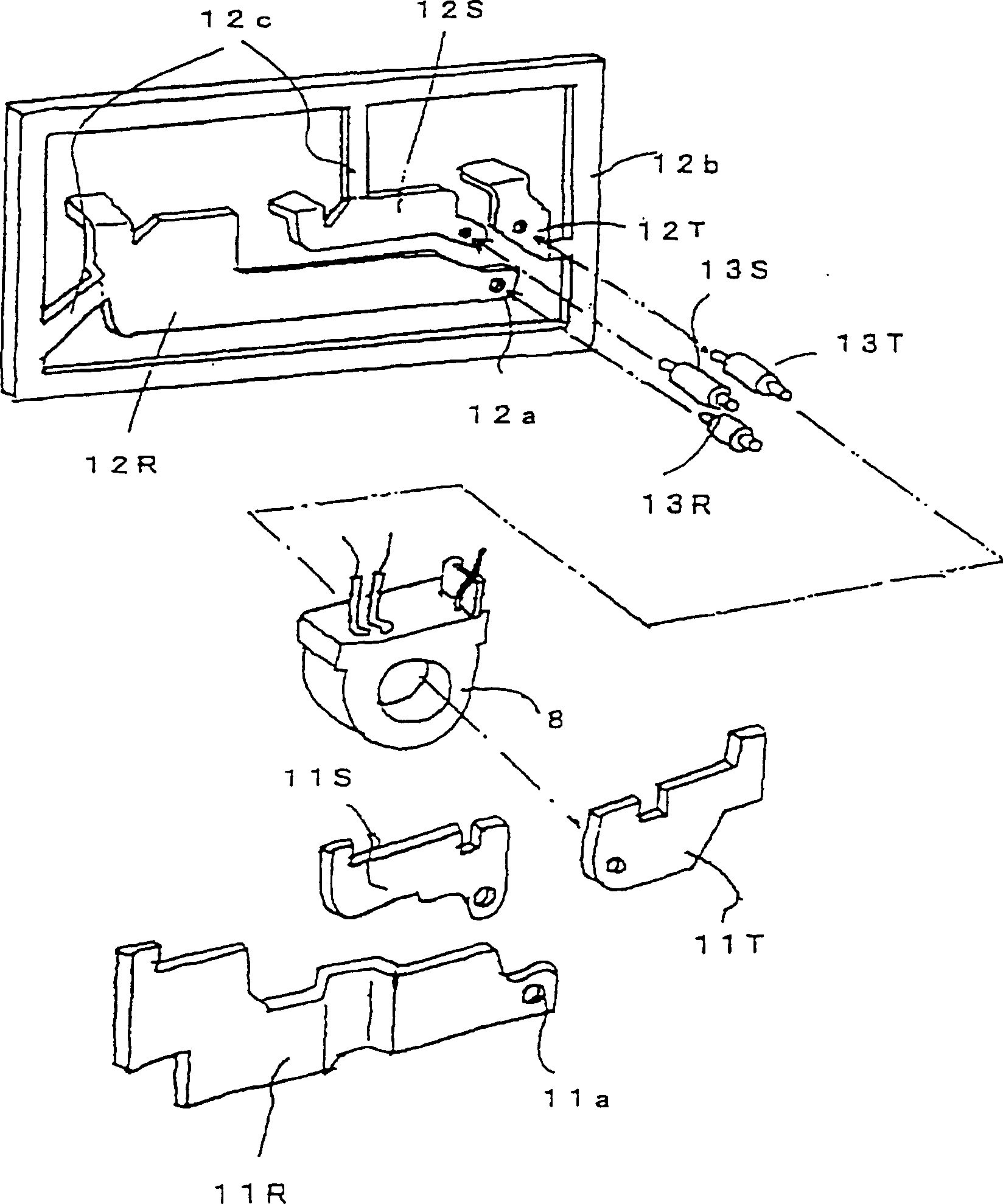

[0028] In the attached picture, figure 1 (a) and (b) show the appearance of the finished product of the zero-phase-sequence converter unit, figure 2 (a) and (b) show the appearance of the tentative assembled state before the resin molding process, image 3 Shown is an exploded view of the individual parts at the stage prior to provisional assembly, Figure 4 (a)-(c) shows the structure diagram of the zero-phase-sequence converter. In addition, in each figure, 8 is a zero-phase-sequence converter, 11R, 11S, 11T and 12R, 12S, 12T are respectively arranged on both sides of the zero-phase-sequence converter 8, and R, S, T The flat conductors of each corresponding primary conductor, 13R, 13S, 13T pass through the primary conductor through hole 8a of the zero-phase sequence converter 8 and connect the flat conductors 11R, 11S, 11T with 12R, 12S, 12T Connection,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com