A composite manufacturing method for connecting and forming metal plate parts based on high-speed impact

A high-speed impact and manufacturing method technology, which is applied in the field of metal plate connection and forming composite manufacturing, to achieve the effects of reducing forming processes, good surface quality, and improving material properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The 0.5mm thick 5083 aluminum alloy is used as the base plate, and the 2mm thick pure titanium is used as the reinforcing plate to realize the connection and forming compound high-speed manufacturing.

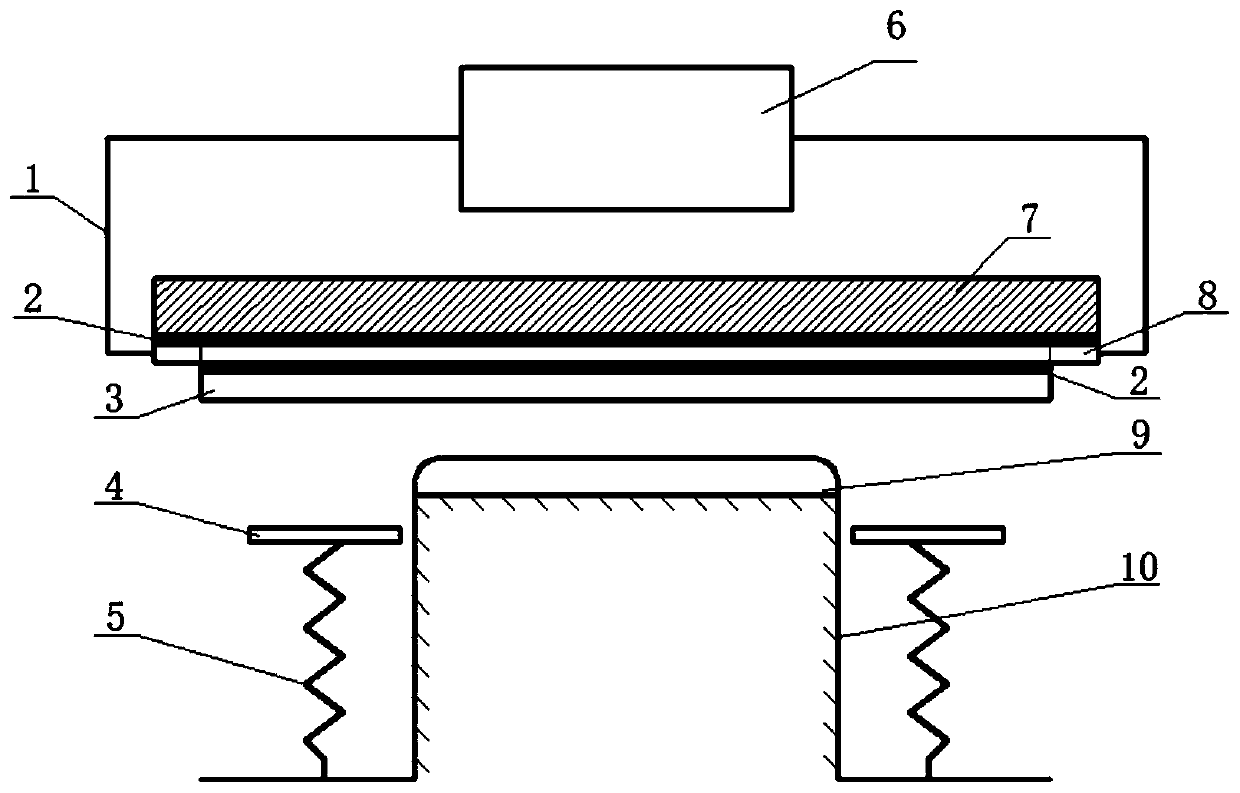

[0044] 1) At room temperature, as attached figure 1 Put the pure titanium 9 on the corresponding mold 10, place the 5083 aluminum alloy 3 at a position 2.5mm above the reinforcing plate 9, and connect the two ends of the 0.05mm thick aluminum foil 8 to the capacitor 6 through the wire 1, and the aluminum foil 8 is passed through the polyurethane The adhesive tape 2 is separated from the fixing block 7 and the substrate 3 respectively;

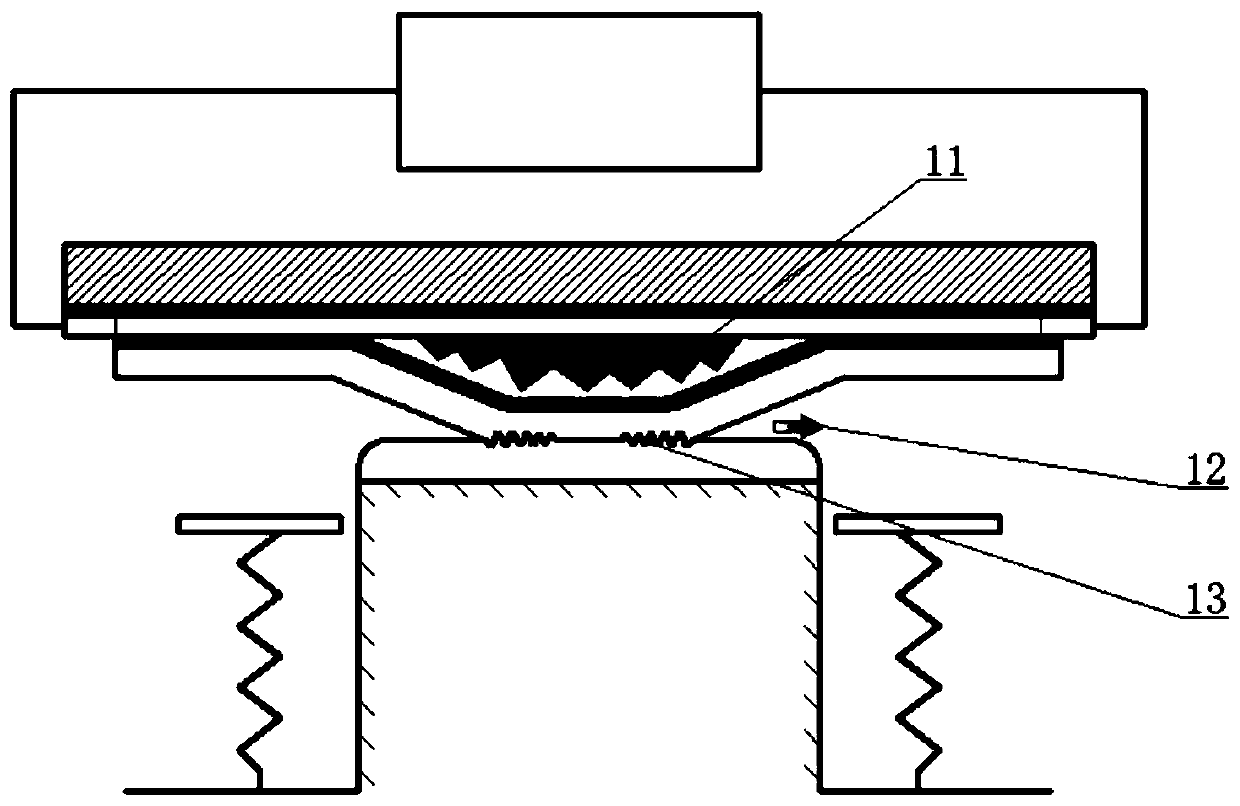

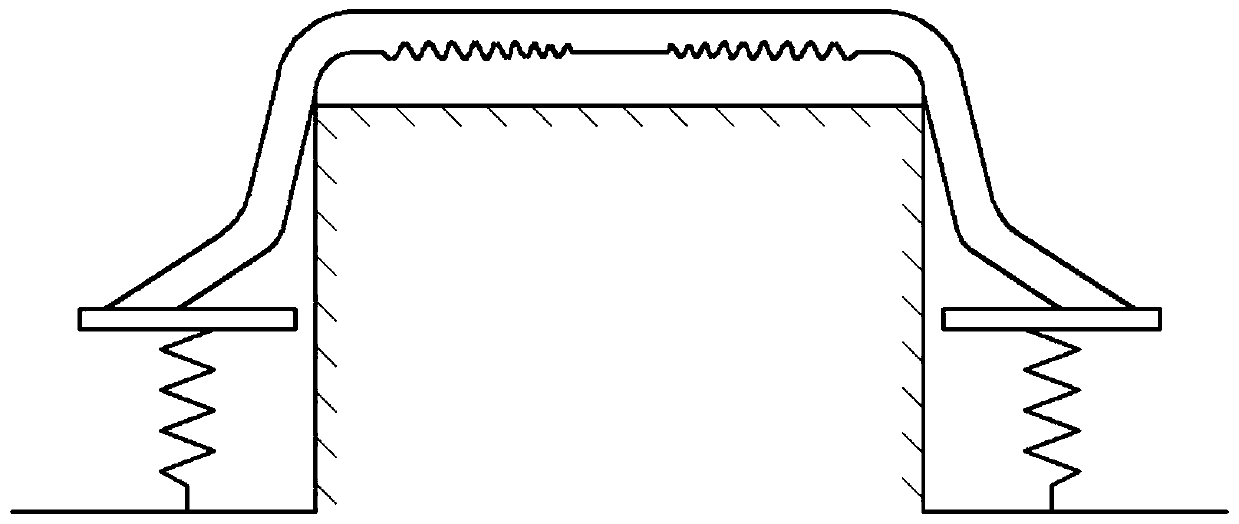

[0045] 2) As attached figure 2 , the capacitor 6 releases 15KJ of energy, and the high-intensity current passes through the aluminum foil 8 instantaneously in about 8 μs, so that the effective area 14 of the aluminum foil 8 (as attached Image 6 ) is vaporized to generate a local high pressure of about 103-104 MPA, and under the constr...

Embodiment 2

[0050] The 1.5mm thick H62 copper alloy is used as the substrate, and the 3mm thick DP780 steel is used as the reinforcement plate to realize connection and forming compound high-speed manufacturing.

[0051] 1) At room temperature, as attached figure 1 Put the DP780 steel 9 on the corresponding mold 10, place the H62 copper alloy 3 at a position 1mm above the reinforcing plate 9, and connect the two ends of the 0.15mm thick aluminum foil 8 to the capacitor 6 through the wire 1, and the aluminum foil 8 is passed through the polyurethane tape 2 are separated from the fixed block 7 and the base plate 3 respectively;

[0052] 2) As attached figure 2 , the capacitor 6 releases 5KJ of energy, and the high-intensity current passes through the aluminum foil 8 instantaneously in about 12 μs, so that the effective area 14 of the aluminum foil 8 (as attached Image 6 ) is vaporized to generate a local high pressure of about 103-104 MPA, and under the constraint of the fixed block 7, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com