Method and apparatus for manufacturing products with unitary casing and body

A technology for manufacturing devices and manufacturing methods, which is applied in the field of manufacturing and devices for integrally formed skin products, and can solve problems such as being unsuitable for mass production and not being able to improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

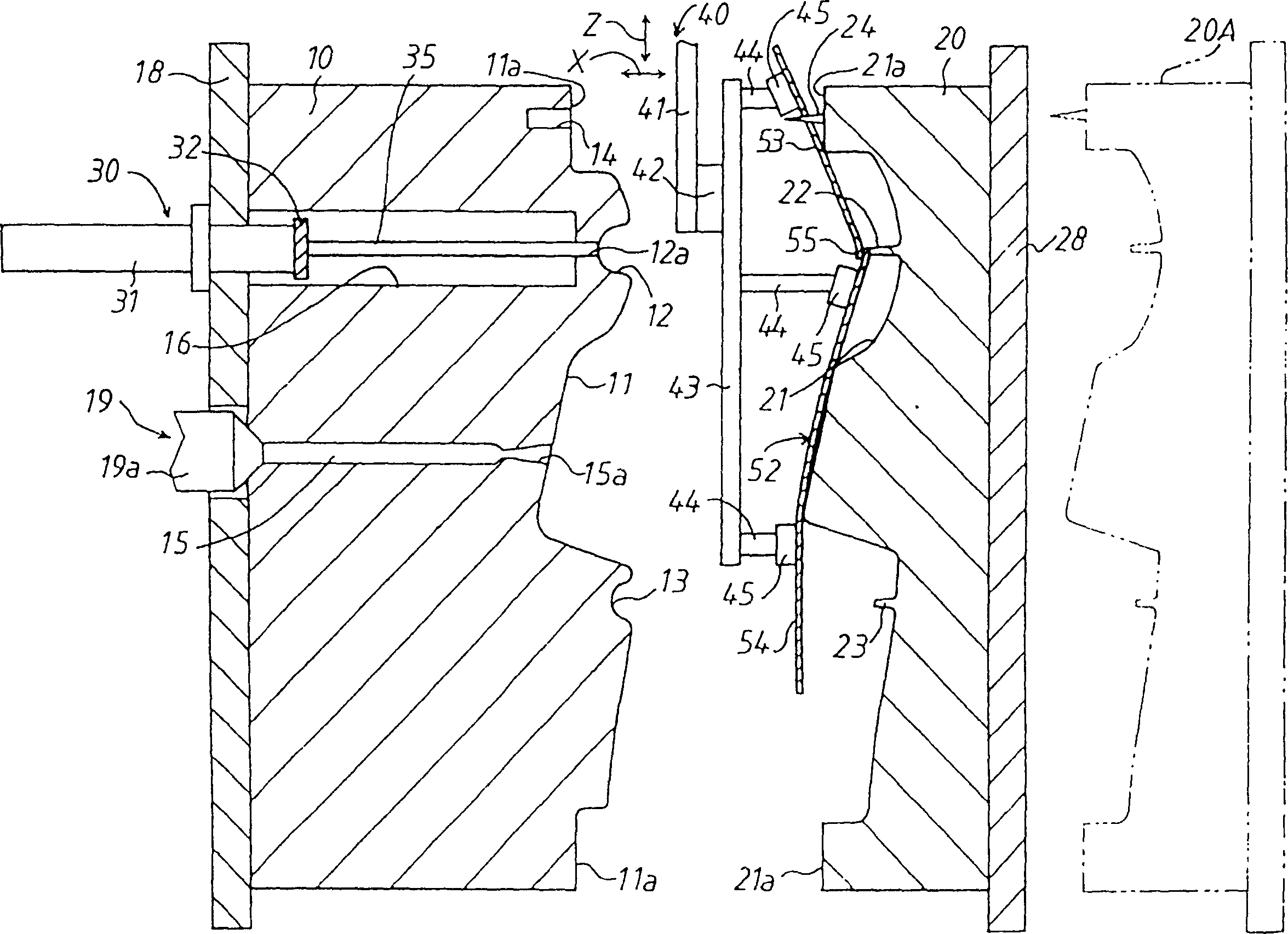

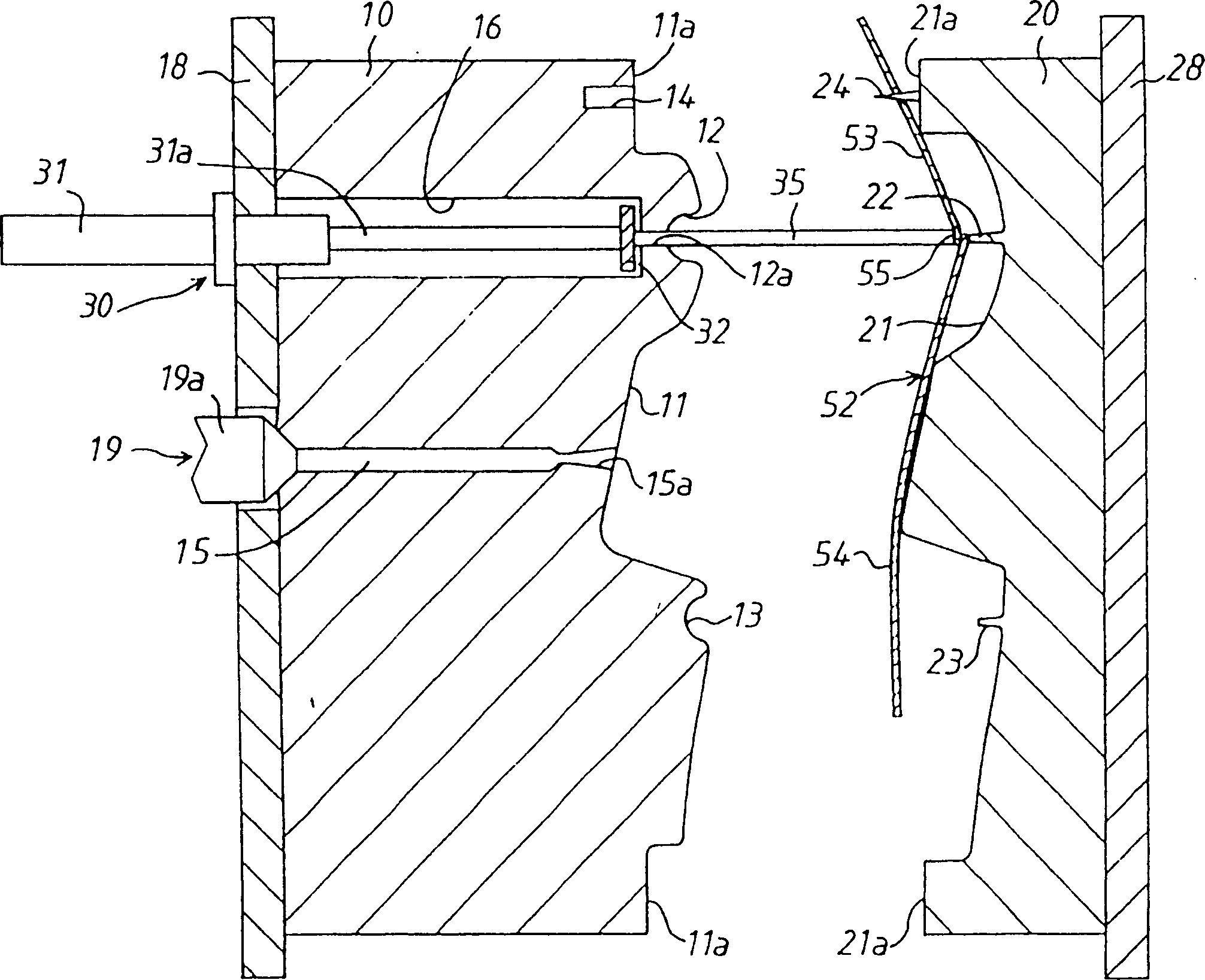

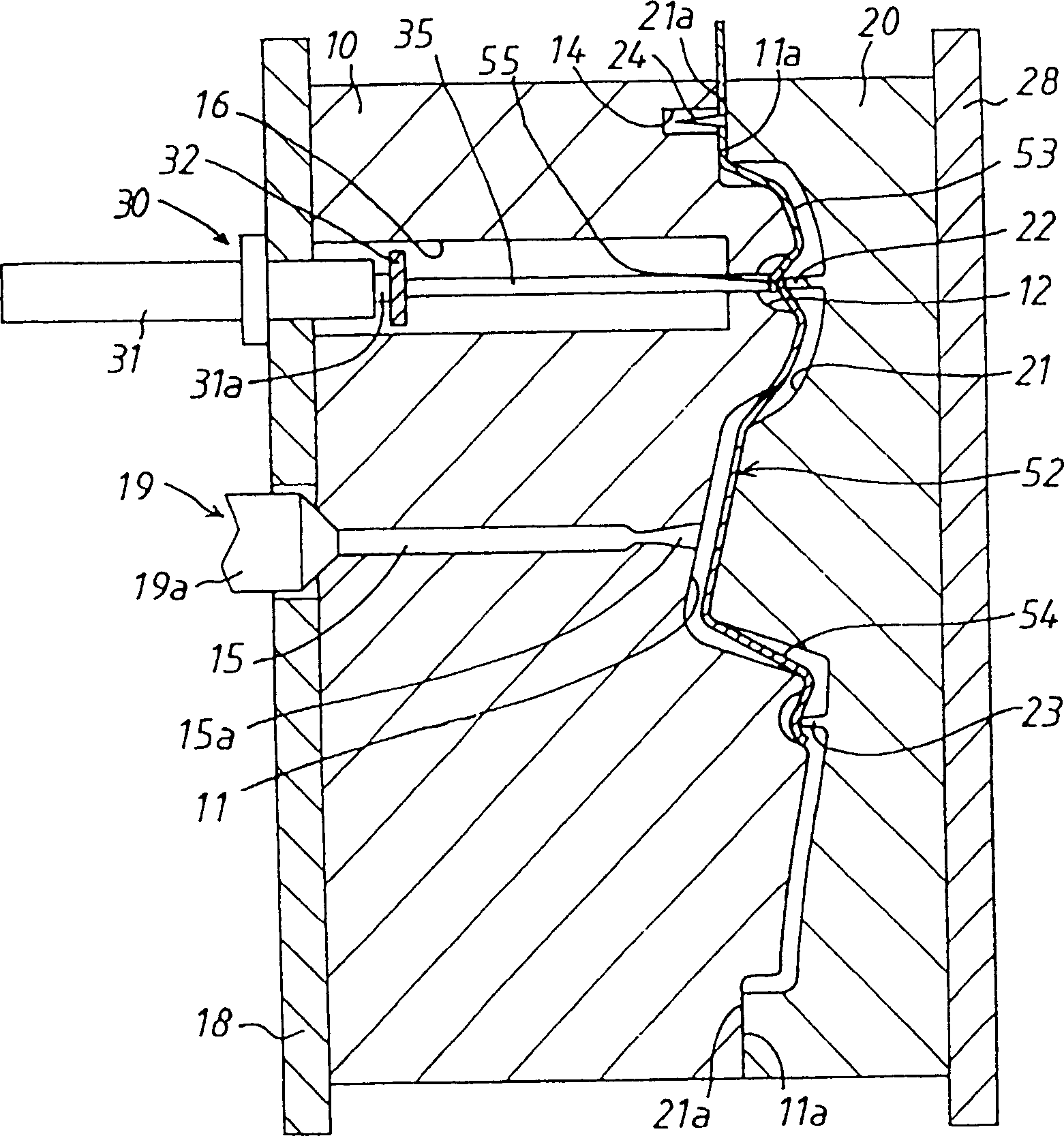

[0038] Refer to the attached Figure 1 to Figure 9 An embodiment in which the present invention is applied to automobile door decoration will be described. Such as Figure 8 As shown, the door trim M formed by the present invention is formed by covering a part of the outer surface of a rigid base material 51 having a substantially constant thickness with a soft skin 52 . A substantially horizontal border slit groove 56 is formed on the front surface side of the skin 52 of the door trim M, and its upper side and lower side are different in color or shape. Peripheral slit grooves 57 are also formed on the outer periphery of the skin 52 to be the interface with the base material 51 .

[0039] First, refer to Figure 1 ~ Figure 4 The forming apparatus used in this example will be described. This forming device comprises a pair of forming molds 10, 20 (core mold 10 and cavity mold 20) that can be separated in the horizontal direction. Draw), the cavity mold 20 on the right side ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com