Process and mould for forming food or beverage container with plant fibres

A molding process and plant fiber technology, applied in textiles and papermaking, etc., can solve the problems of slow heat transfer, short service life, long molding time, etc., achieve uniform heating energy consumption, solve mold blockage, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

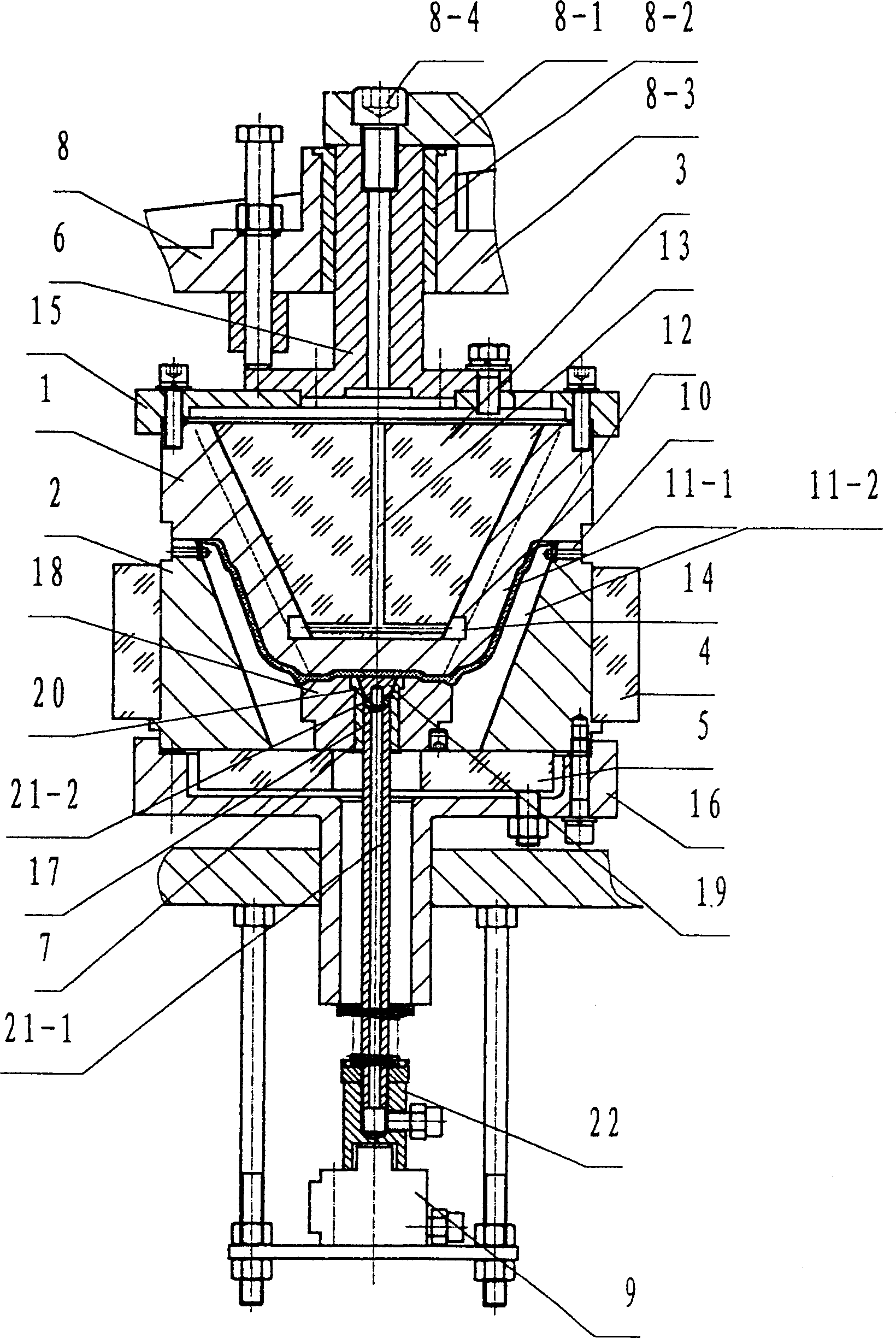

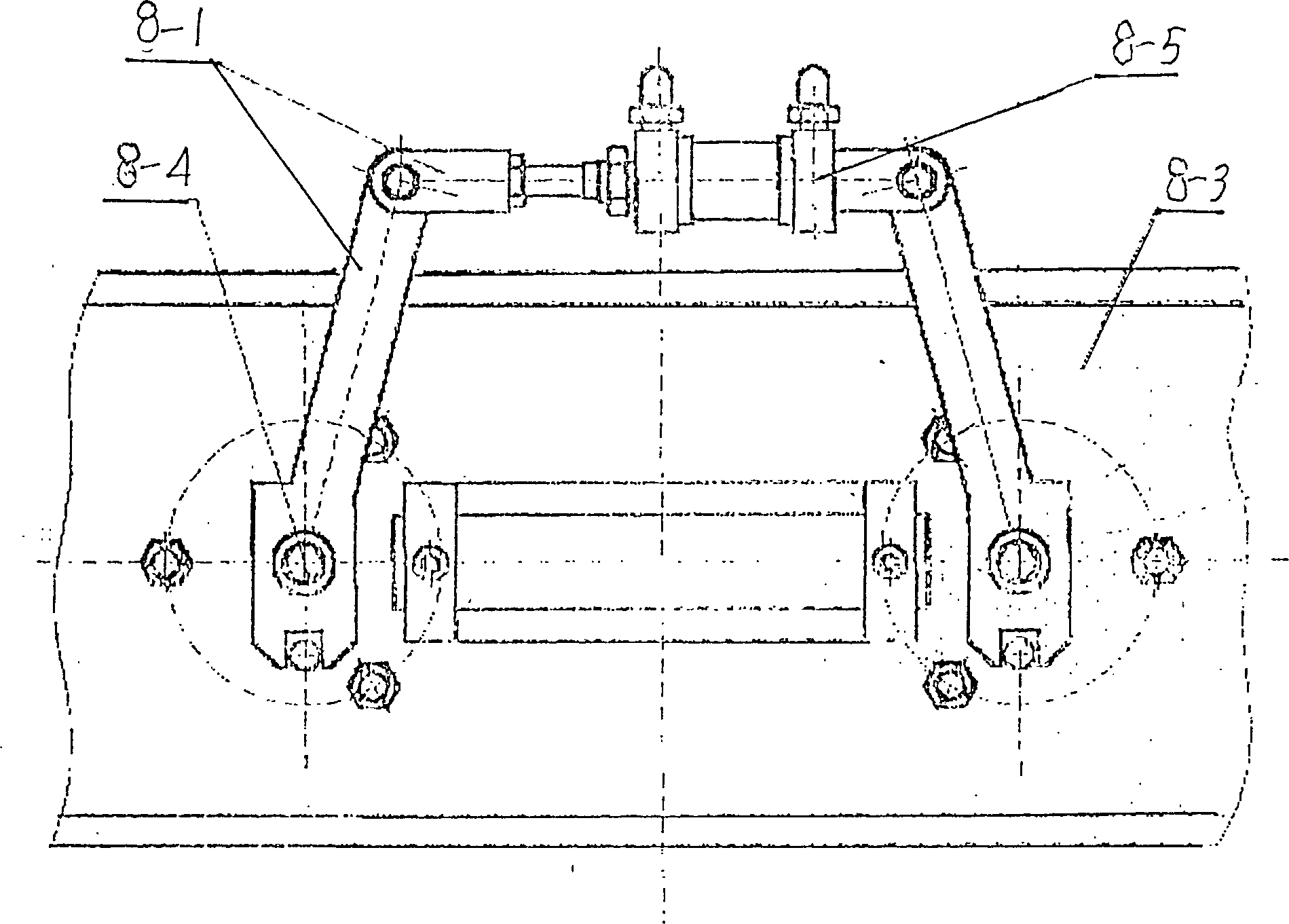

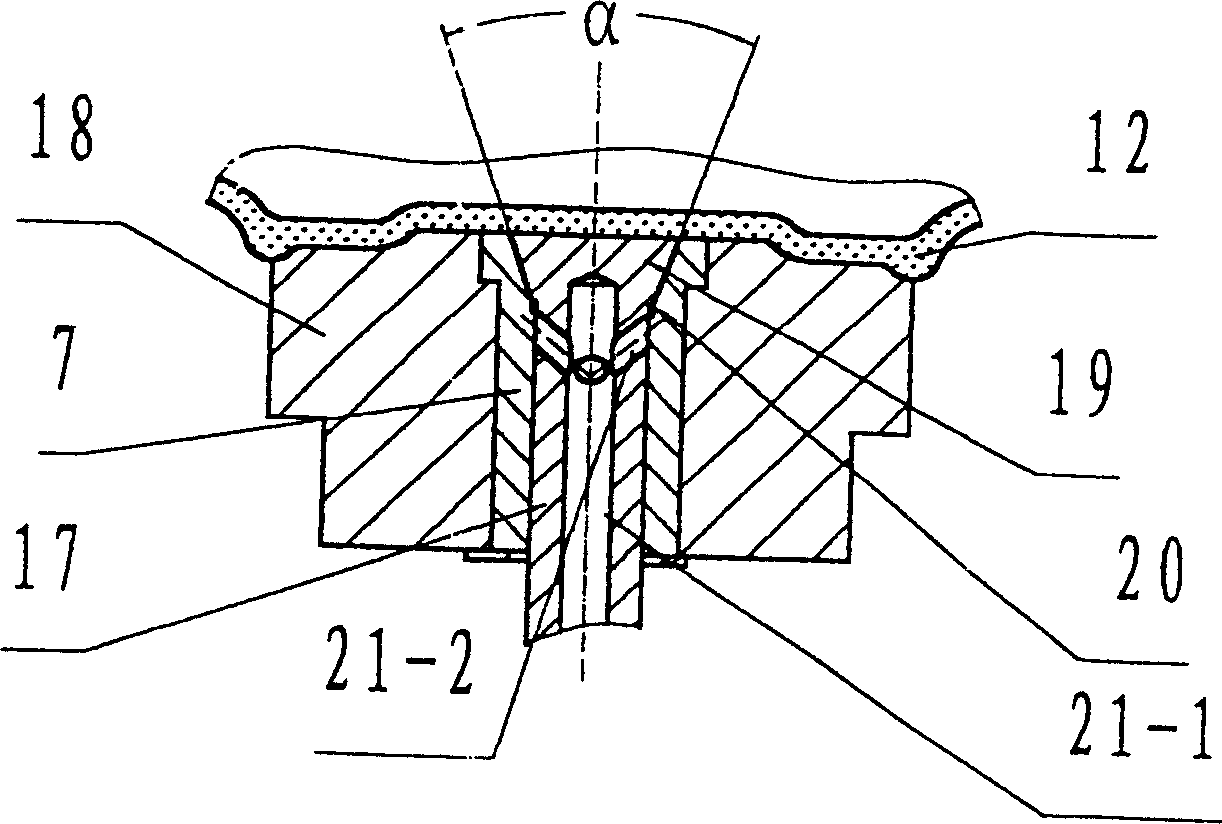

[0018] The upper die holder 15 is connected with the upper die 1 and the positioning flange 6 by screws, the lower die holder 16 is connected with the lower die 2, the blocking block 18 is fixed on the lower die 2 with the seam screws, and the ejector rod guide sleeve 7 is used with the retaining ring for the shaft Fixed on the bottom of the lower mold 2, the ejector rod 17 is connected with the guide sleeve 7 by pipe thread, and the upper joint surface 20 between the two, and the ejector rod 17 is controlled by the thin cylinder 9 as a pneumatic actuator to control the opening of the upper joint surface 20 between the two. closed (see figure 1 ), the hollow ejector rod is the longitudinal air blow hole 21-1, the upper port of which communicates with the transverse air blow hole 21-2, and the transverse air blow hole 21-2 communicates with the gap when the joint surface of the ejector block and the guide sleeve is pulled apart, and the ejector rod The lower end is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com