Ultrasonic cross shot peening of vanes on rotor

A shot peening device and shot peening technology, which are applied to the supporting elements of blades, vibration devices, explosion generating devices, etc., can solve problems such as loss of kinetic energy of particles, uneven shot peening, and increased shot peening time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

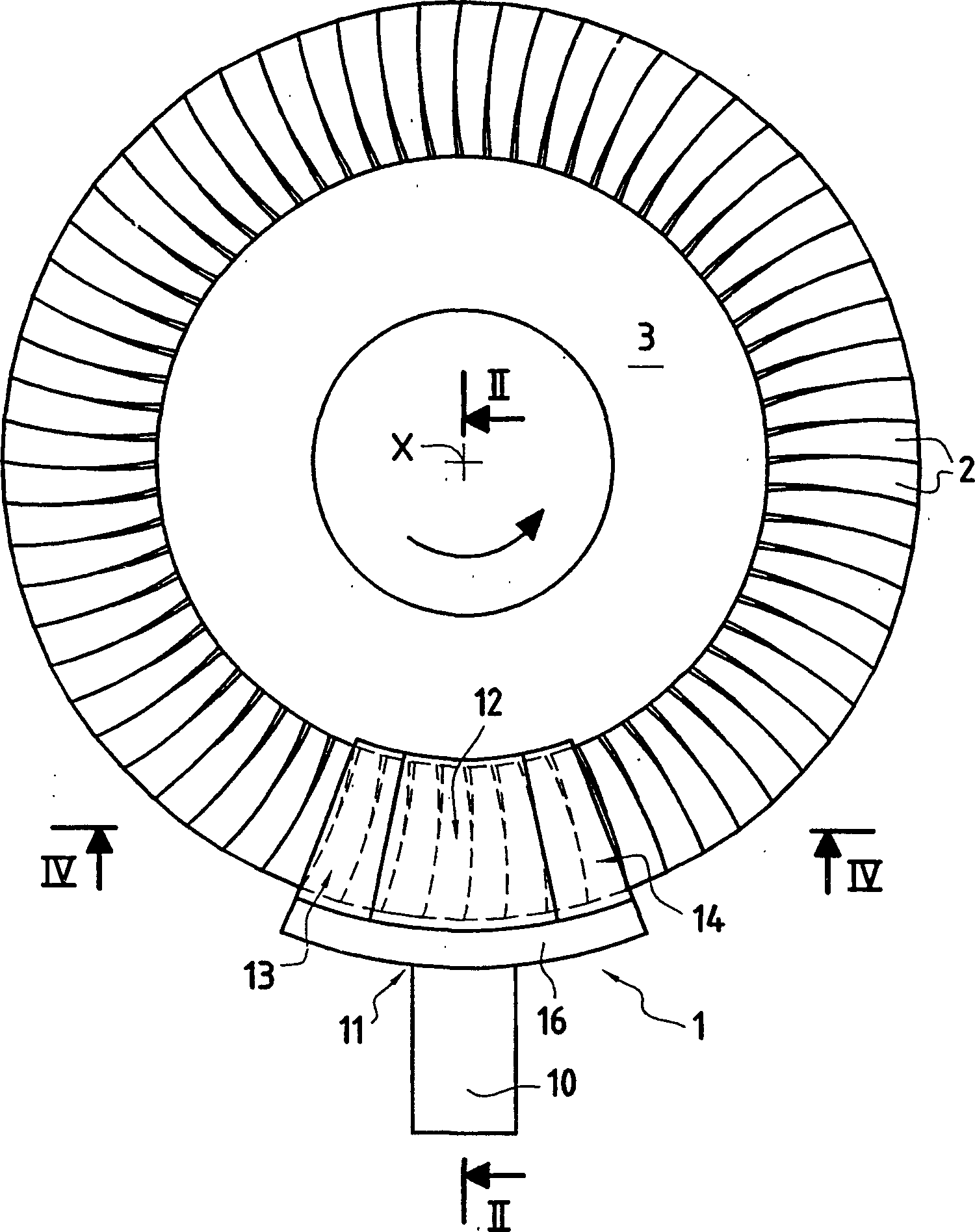

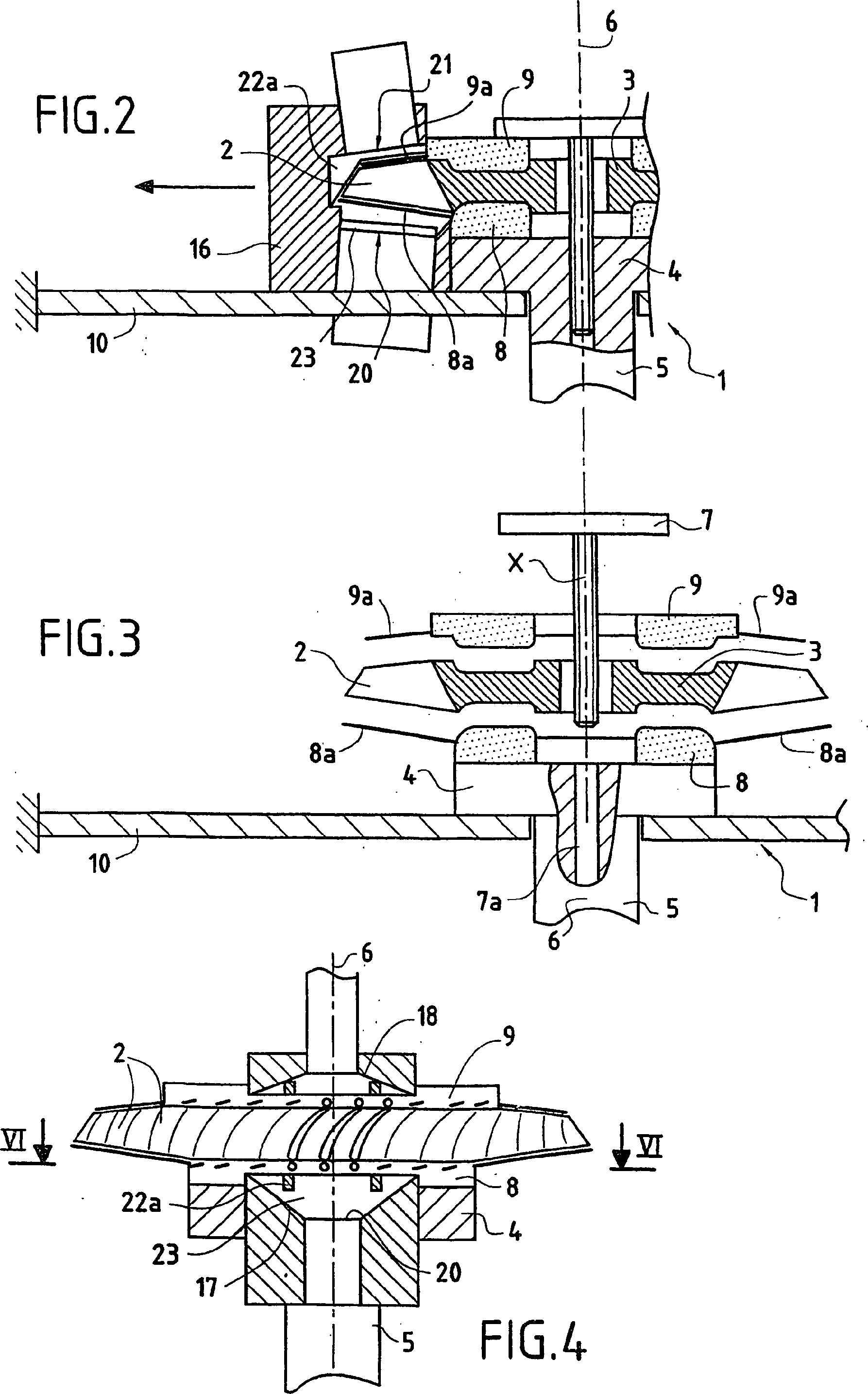

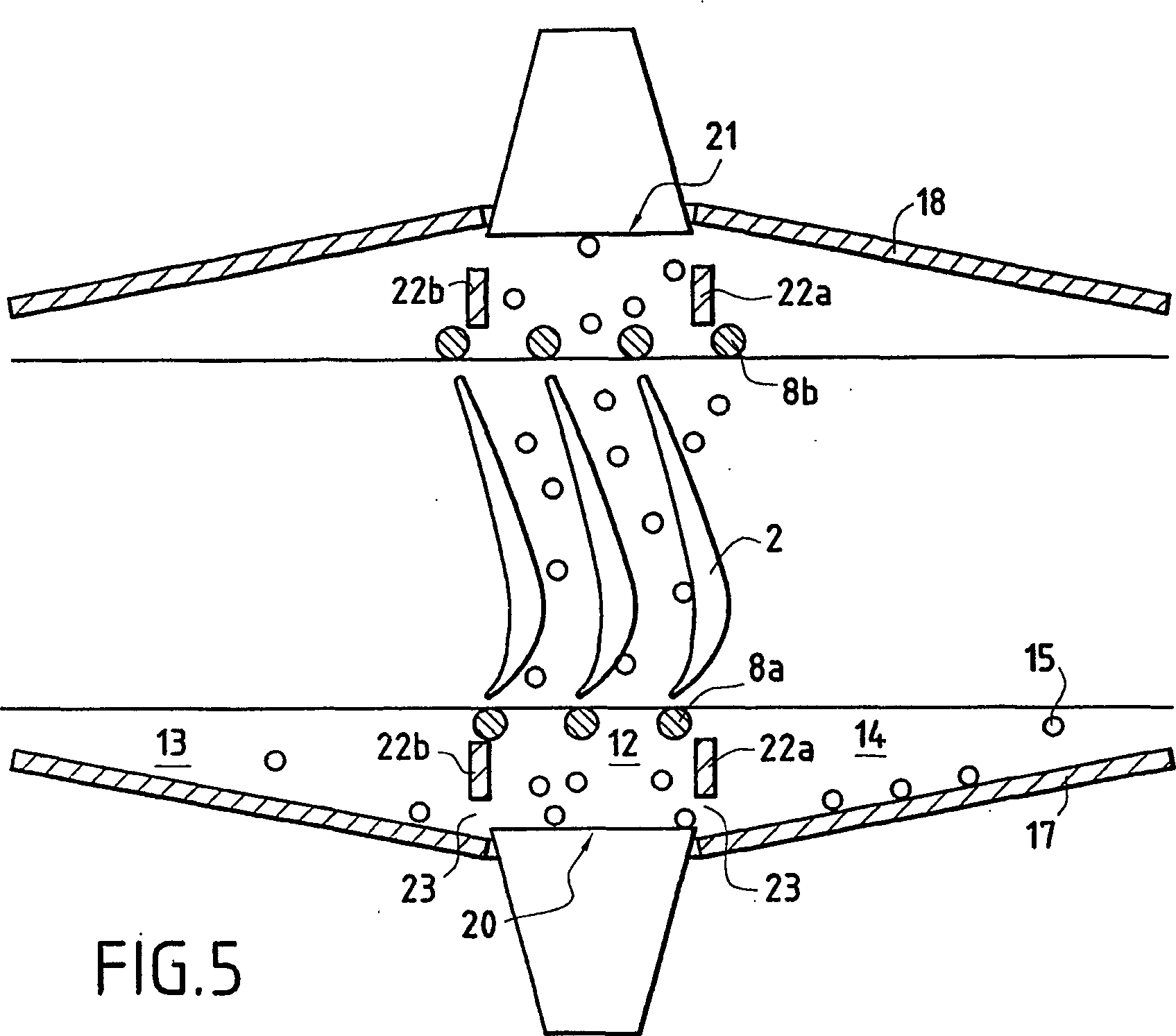

[0044] In these figures, number 1 is the shot blasting machine, the blades 2 are distributed radially around the flywheel 3, and the axis of the turbine is x. The flywheel 3 may be a single disc with blades or the flywheel of a turbine with movable blades. Blades 2 can also be parts whose surfaces should be shot-peened and have radially mounted flywheels 3 for supporting the parts to be shot-peened.

[0045] The shot blasting machine 1 basically has a rotating platform 4 supported by an axis 5 of axes 6 . The shaft 5 is driven in rotation about an axis 6, the driving means, such as a motor, not being shown in the figure. The flywheel 3 is fixed on the rotary platform 4 by means of the flange 7 and the reaming hole 7a of the shaft 6 punched out on the rotary platform, and its axis x should match the shaft 6 of the rotary platform.

[0046] Since this is very evident on FIGS. 2 and 3 , preferably a first annular disc 8 is located between the rotating platform 4 and the flywhee...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap