Rack elevator and loading mechanism

A loading mechanism and lifting device technology, applied in storage devices, transportation and packaging, adjustable cabinets, etc., can solve the problems of increasing the overall size and manufacturing difficulty, high processing costs of coil springs, and difficult layout of buffer devices. To achieve the effects of compact structure, easy manufacture, and expanded load range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

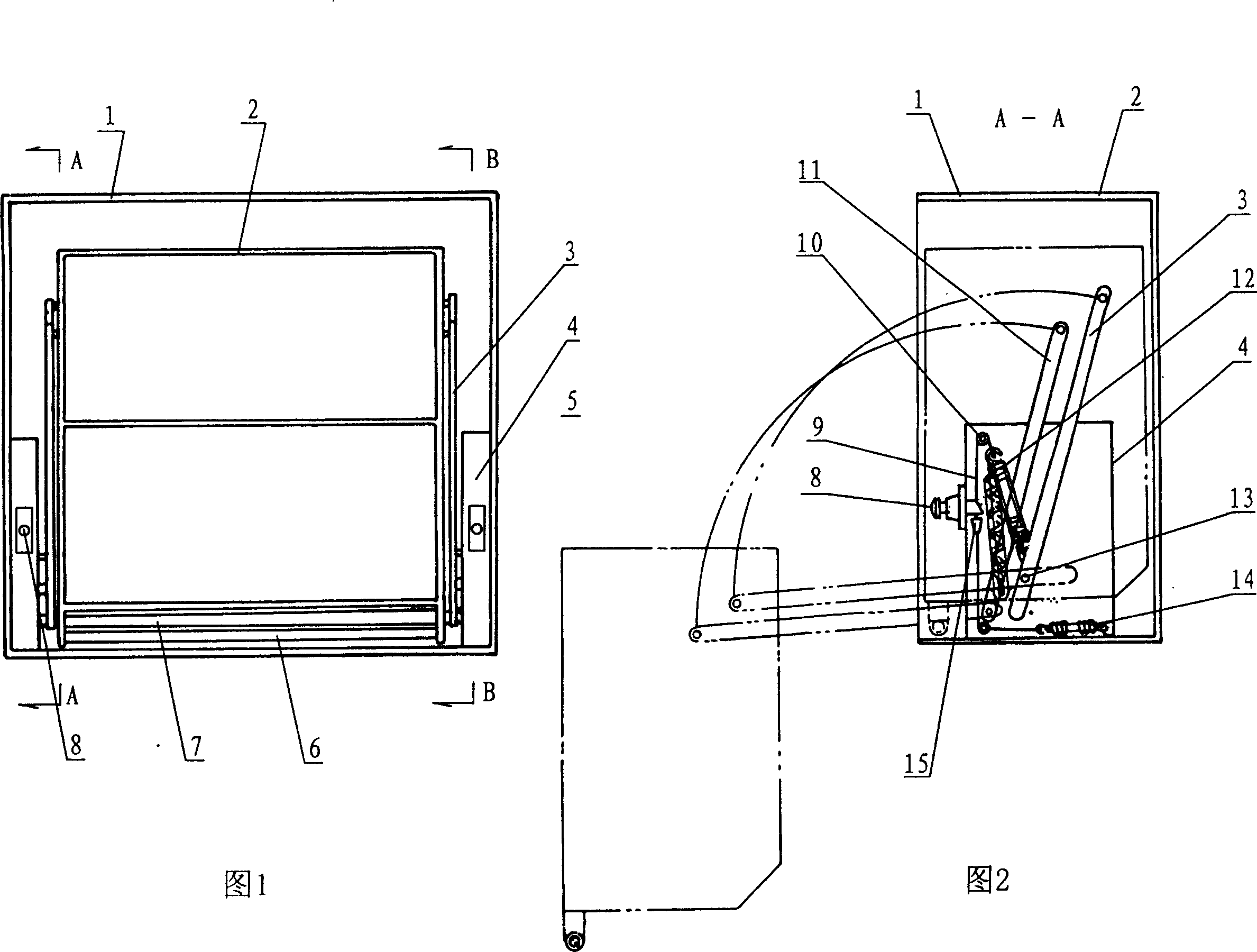

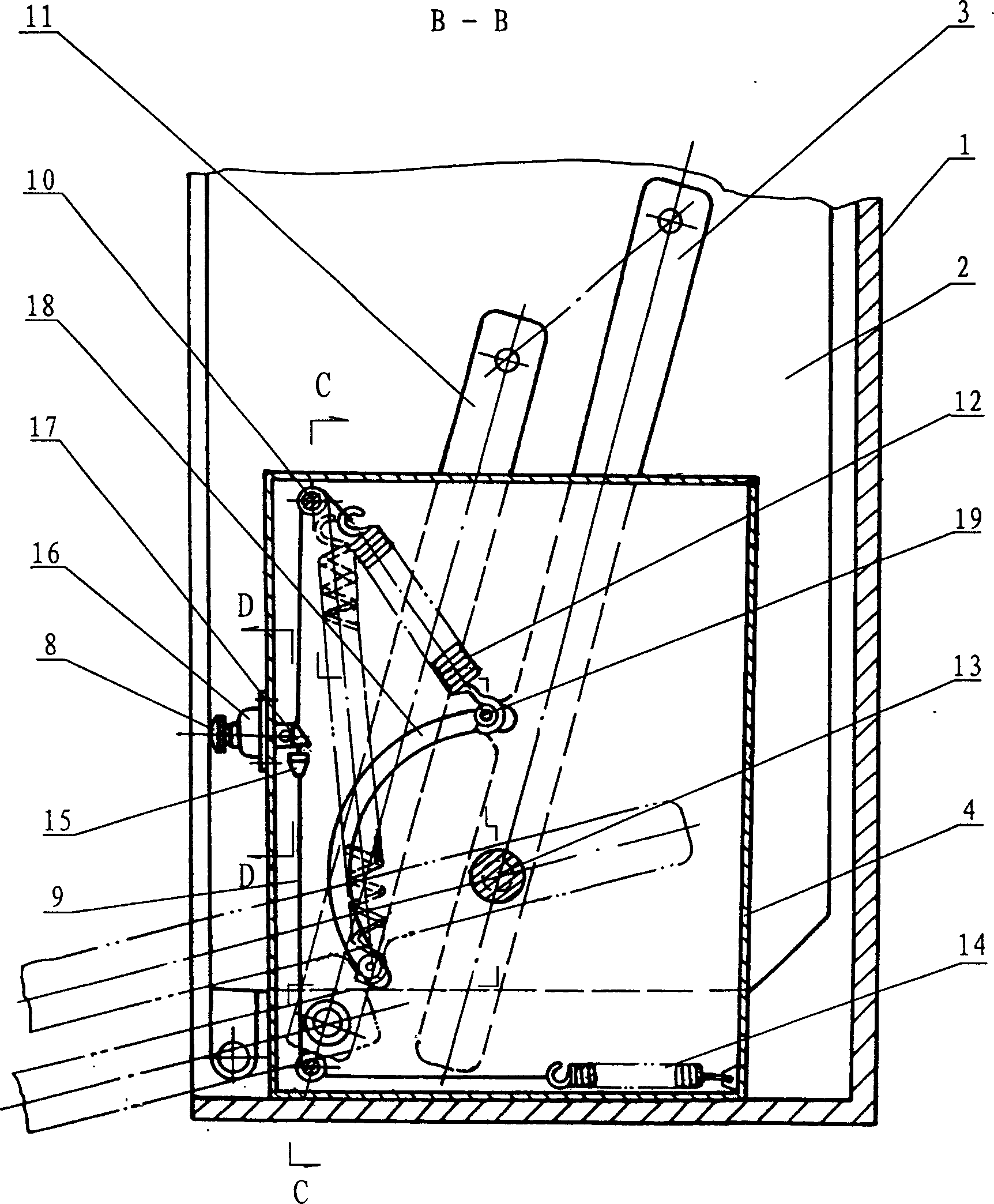

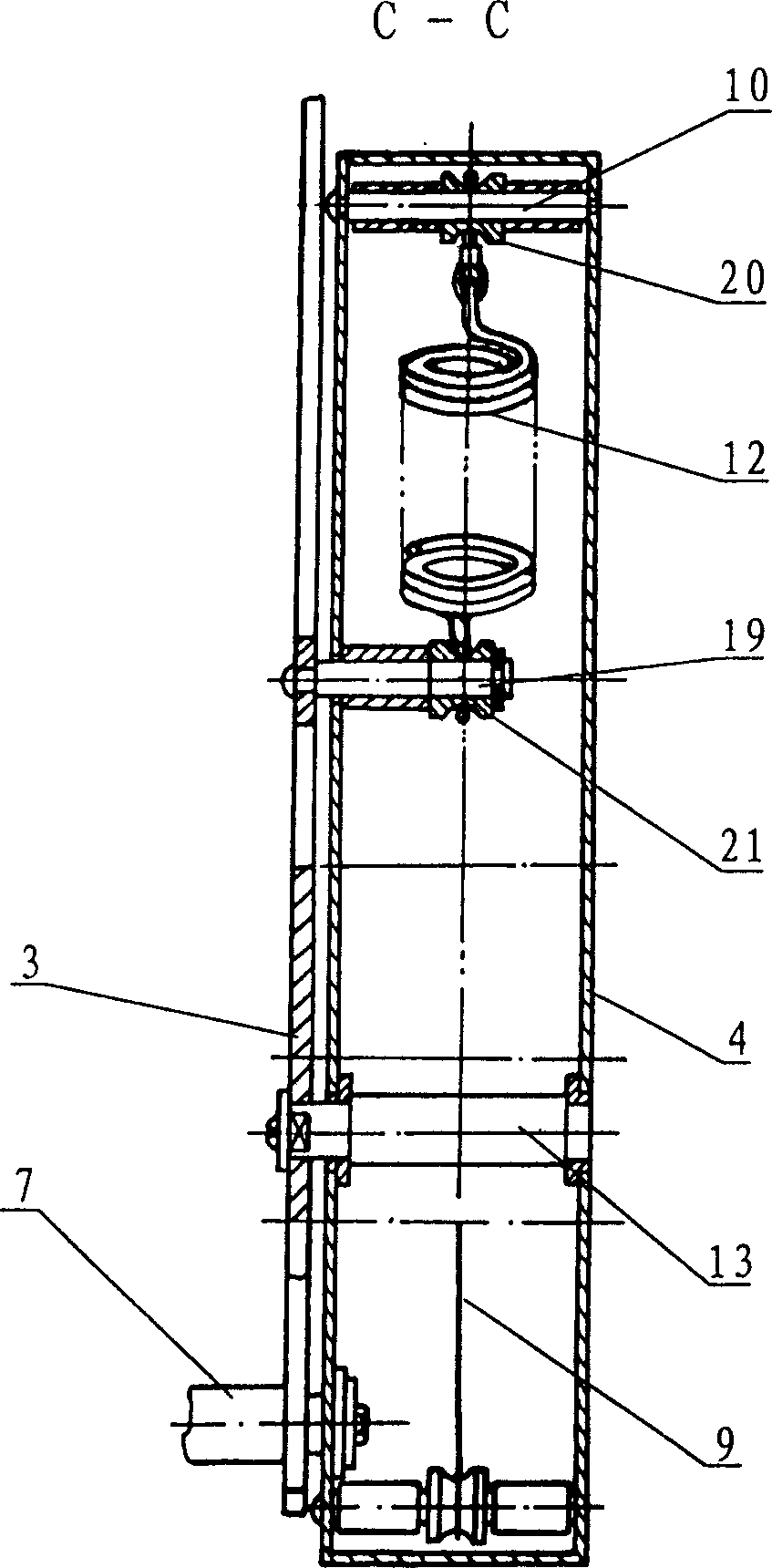

[0018] The specific structure of the present invention will be described in detail according to Figs. 1-6. This device is improved on the basis of the structure of the original "storage rack lifting device", except that the locker 1 in the original device and the storage rack 2 assembled in it and the left and right active connecting Xuan 3 and the left and right Outside the basic structure of components such as driven link 11 and left and right lift controllers, in its left and right lift controller housings 4, a backup accumulator 12 for loading is respectively set. The balance force and energy storage capacity of the two backup energy storage devices 12 can be the same or different. They can be loaded separately or simultaneously. The structure of the backup energy storage device 12 can be a tension spring according to actual needs; a pneumatic cylinder or other energy storage damping buffer device can also be selected. In this embodiment, the backup energy storage device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com