Multi-function monitoring module for printer

A technology of printers and printing media, applied in printing devices, printing, electrical components, etc., can solve troublesome and time-consuming problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

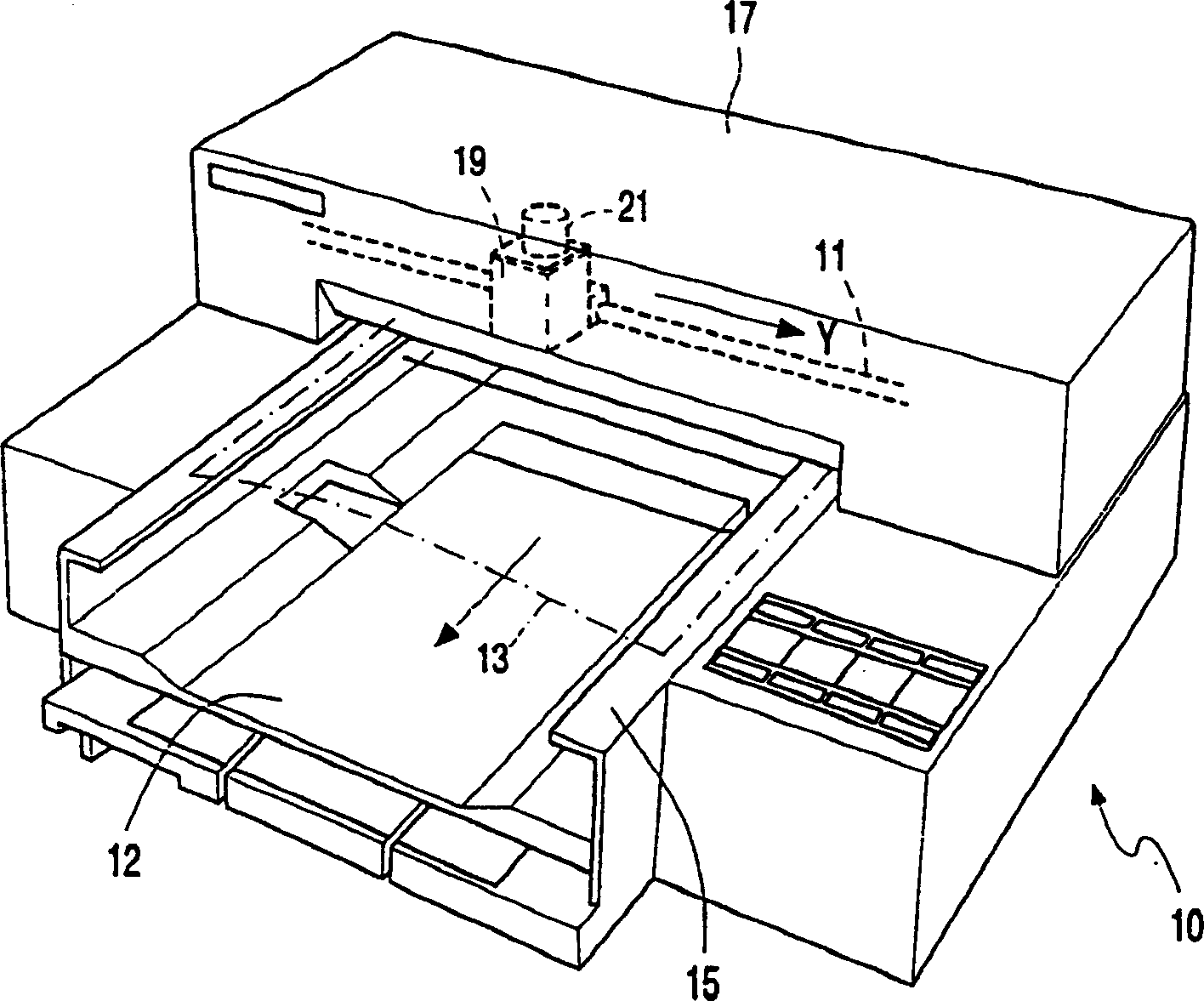

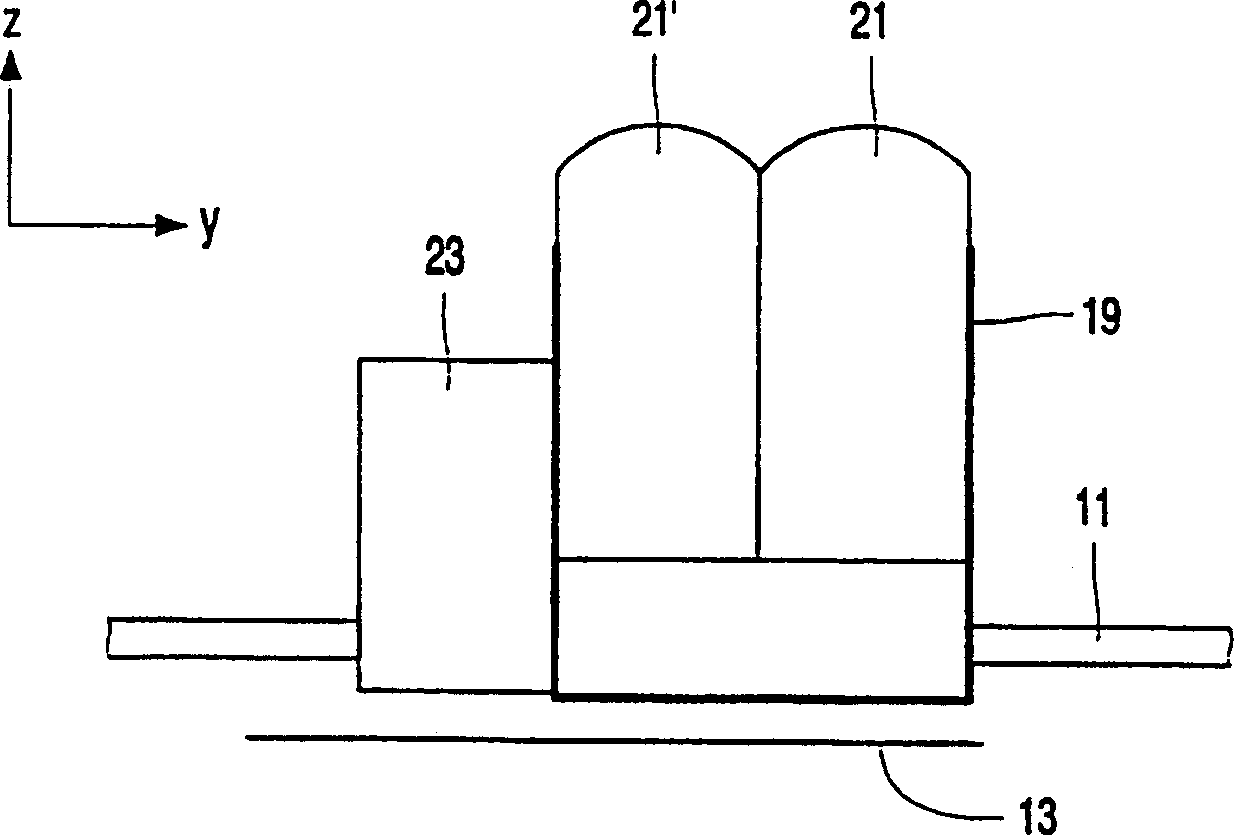

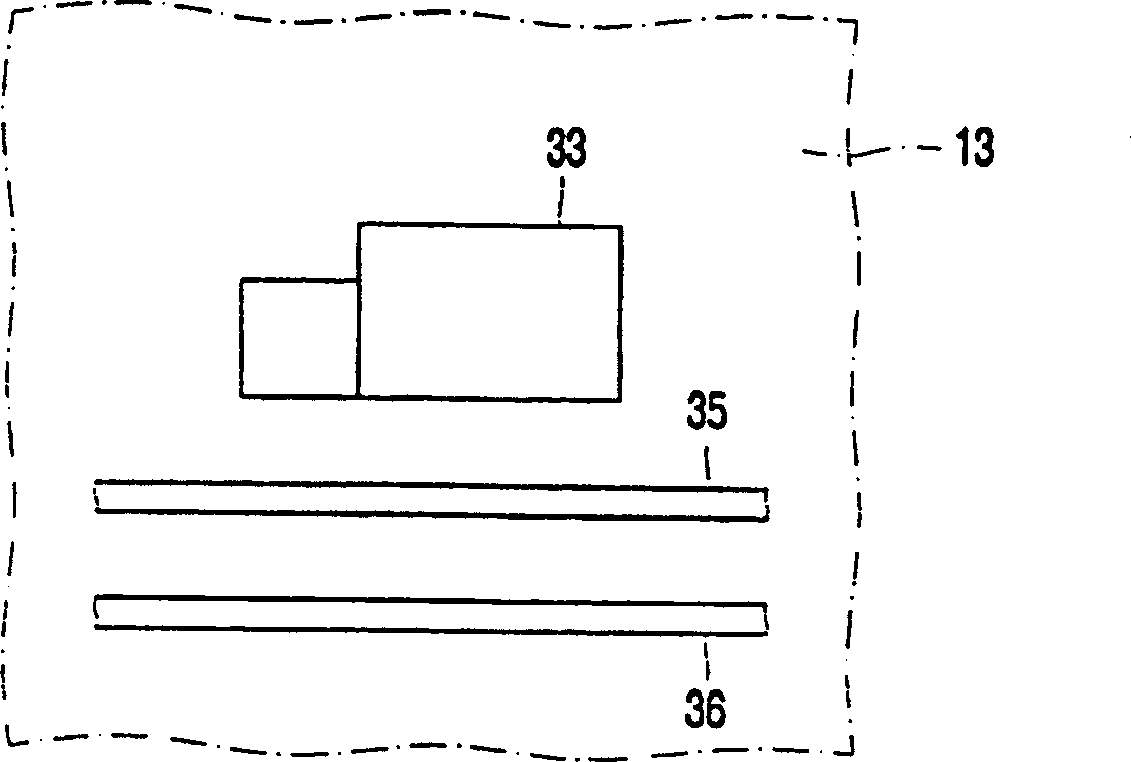

[0070] figure 1 An embodiment of an inkjet printer 10 known from EP-A0641115 is shown. The printer has an internal frame comprising crossbars 11 extending in the Y direction. The inner frame defines a print medium passage 12 through which print medium can pass in the X direction. A sheet of print paper 13 is shown passing through the print media path suspended from paper guides 14 and 15 . Devices for moving paper through the print medium path are well known and described in figure 1 Not shown in . The inner frame is enclosed by a cover 17 .

[0071] Mounted on the inner frame is a bracket 19 which houses a writing device or inkjet cartridge 21 . Means for moving the carriage 19 in the Y direction are not shown. These devices are well known in the art. Generally, when the carriage completes one movement along the Y direction on the paper, the printing paper in the inkjet printer is displaced along the X direction. The displacement range of the printing paper depends on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com