Resistance adjustable gas distributing device for fluid material

A gas distribution and adjustable technology, which is applied in the direction of conveying bulk materials, chemical/physical processes, transportation and packaging, etc., can solve the problems of different internal structures, no adjustment of resistance characteristics, etc., and achieve the effect of reducing process costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The invention is a gas distribution device for fluidized materials in a fluidized bed. The fluidized bed generally has a space to accommodate fluidized materials, and an air distribution plate or air distribution device for installing a gas distribution device, that is, an air cap. Below the air distribution plate or air distribution device is used for introducing and mixing Air chamber or bellows for fluidizing gas.

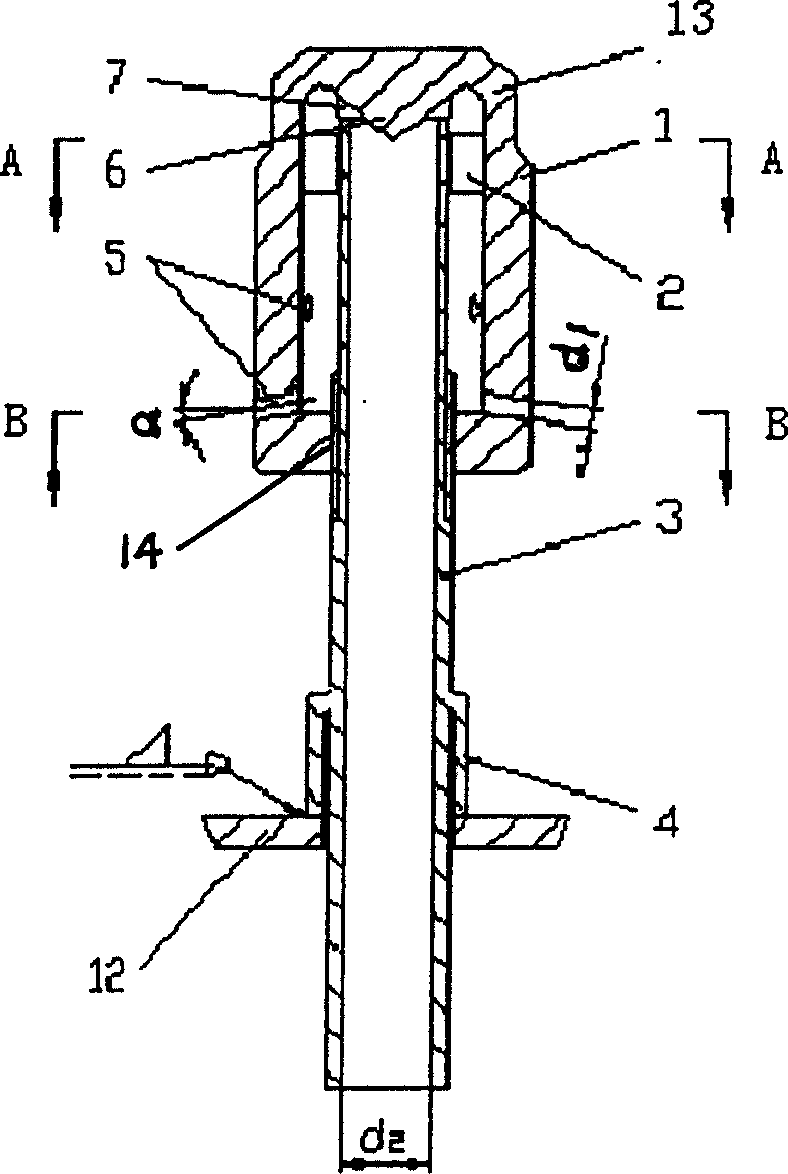

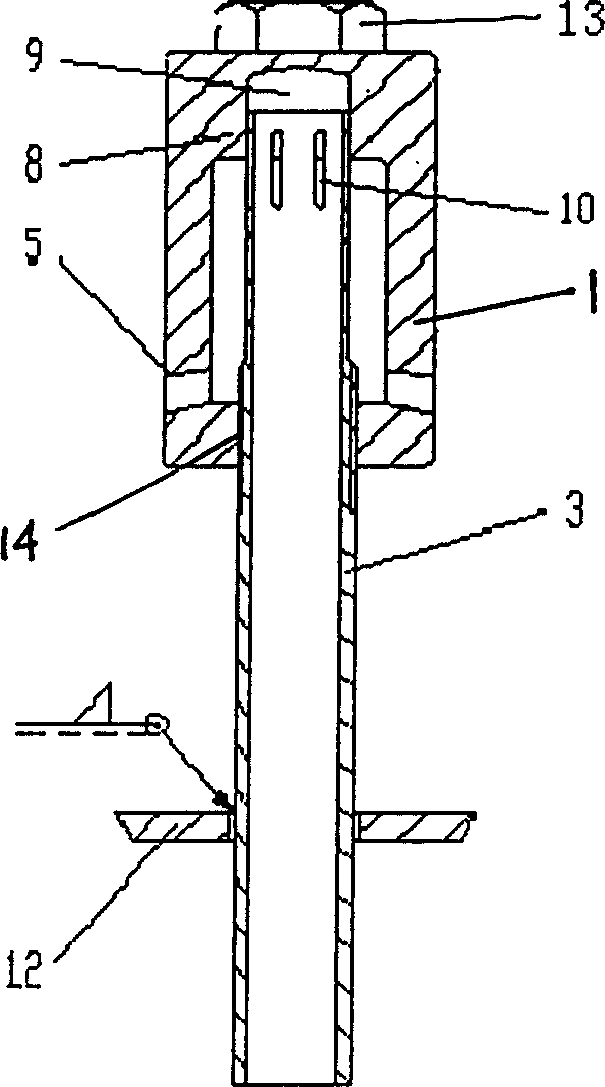

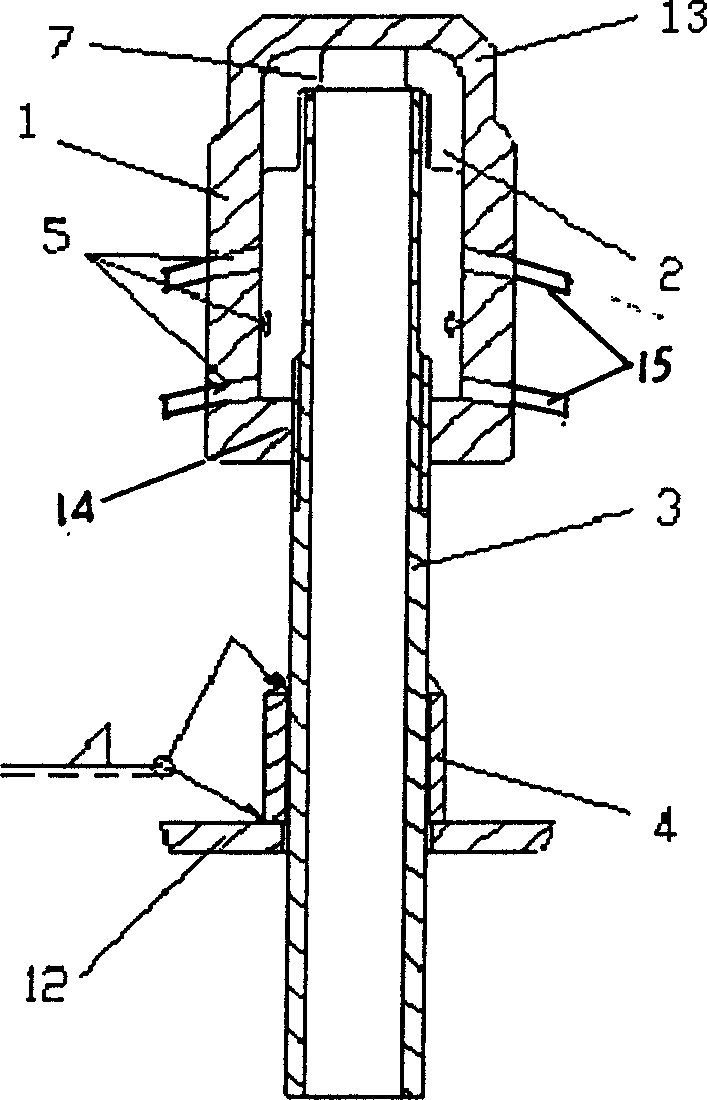

[0038] As shown in the figure: the adjustable resistance gas distribution device has a cylindrical shape and is divided into upper and lower parts. It is used to guide the fluidizing gas from the bellows or wind chamber into the air intake pipe 3 of the resistance-adjustable gas distribution device. The distribution head 1 and the air inlet pipe 3 are coaxially arranged and threaded.

[0039]The upper section or top of the distribution head 1 is processed into a nut-like polygonal column 13 with at least three faces, so as to facilitate the disassembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com