A kind of multi-layer fluidized bed for the alkylation reaction of phenolic compound and its application

A phenolic compound and alkylation reaction technology, applied in the field of multi-layer fluidized bed, can solve the problems of no fluidized bed reactor, such as alkylphenolic compound, easy penetration and escape of alkylating agent, difficult separation, etc. The effect of avoiding unstable product composition, reducing residence time and reducing side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

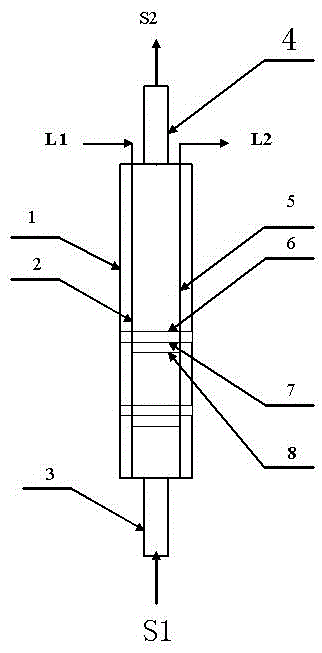

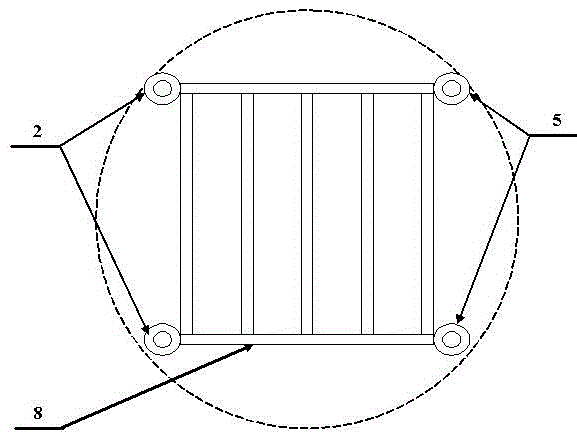

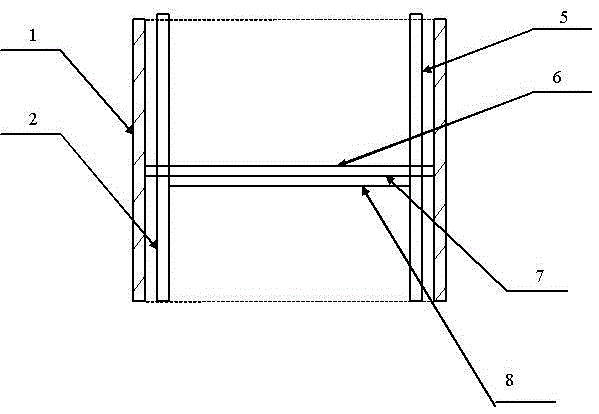

[0029] A cylindrical fluidized bed cylinder is used, in which 5 layers of composite baffles are placed. Each composite baffle is composed of horizontal pipes, coarse screens, and fine screens. From bottom to top, the horizontal pipes, coarse The order of the screen and the fine screen should be installed firmly. All the composite baffles are connected together through 4 risers (including the water inlet riser 2 and the water outlet riser 5) to form a baffle group together. All the horizontal pipes and standpipes forming the baffle group are connected internally and put into the fluidized bed cylinder as a whole from above. When the baffle plate group is put into the fluidized bed cylinder, catalyst particles are placed on each composite baffle, and the static height of the catalyst particle layer is equal to one-half of the inner diameter of the fluidized bed cylinder. Two of the water inlet standpipes are connected to the external water inlet pipes, and two of the water outl...

Embodiment 2

[0033] A cylindrical fluidized bed cylinder is used, in which 6 layers of composite baffles are placed. Each composite baffle is composed of horizontal pipes, coarse screens, and fine screens. From bottom to top, the horizontal pipes, coarse The order of the screen and the fine screen should be installed firmly. All the composite baffles are connected together through 4 risers (including the water inlet riser 2 and the water outlet riser 5) to form a baffle group together. All the horizontal pipes and standpipes forming the baffle group are connected internally and put into the fluidized bed cylinder as a whole from above. When the baffle group is put into the fluidized bed cylinder, catalyst particles are placed on each composite baffle, and the static height of the catalyst particle layer is equal to one-fifth of the inner diameter of the fluidized bed cylinder. Two of the water inlet standpipes are connected to the external water inlet pipes, two of the water outlet riser ...

Embodiment 3

[0037] A cylindrical fluidized bed cylinder is used, in which 4 layers of composite baffles are placed. Each composite baffle is composed of horizontal pipes, coarse screens, and fine screens. From bottom to top, the horizontal pipes, coarse The order of the screen and the fine screen should be installed firmly. All the composite baffles are connected together through 4 risers (including the water inlet riser 2 and the water outlet riser 5) to form a baffle group together. All the horizontal pipes and standpipes forming the baffle group are connected internally and put into the fluidized bed cylinder as a whole from above. When the baffle group is put into the fluidized bed cylinder, catalyst particles are placed on each composite baffle, and the static height of the catalyst particle layer is equal to one-third of the inner diameter of the fluidized bed cylinder. Two of the water inlet standpipes are connected to the external water inlet pipes, two of the water outlet riser ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com