Fluidized bed reaction device and application thereof

A fluidized bed reaction and fluidized bed reactor technology, applied in the directions of organic chemistry, bulk chemical production, chemical instruments and methods, etc., can solve the problems of unfavorable methane conversion rate and C2+ yield, complicated multi-stage fluidized bed process, The catalyst cycle is unstable and other problems, so as to avoid unstable product composition, high heat and mass transfer efficiency, and good gas-solid contact effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

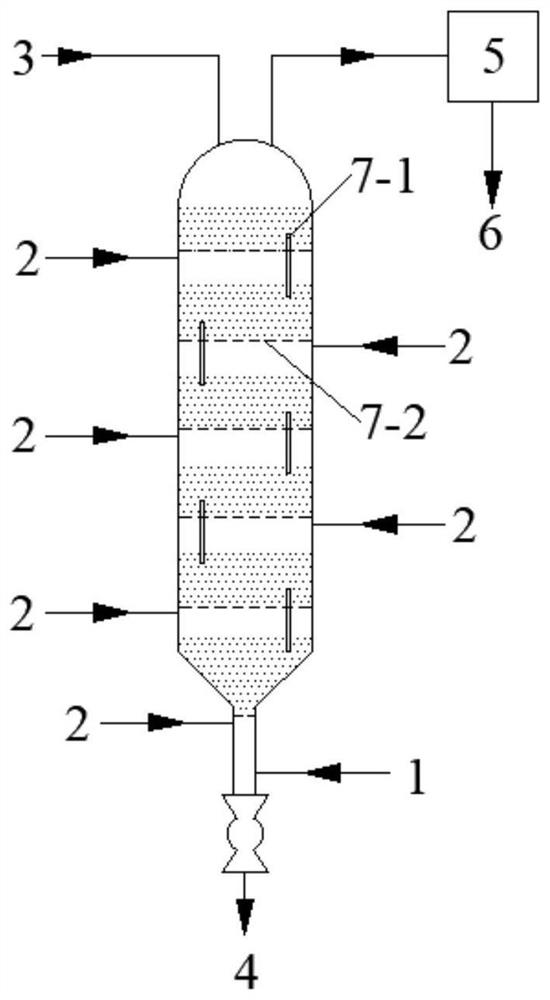

[0060] This embodiment provides a figure 1 The fluidized bed reaction device includes a fluidized bed reactor.

[0061] The top of the fluidized bed reactor is provided with a catalyst inlet and a product gas outlet.

[0062] The bottom of the fluidized bed reactor is provided with a catalyst outlet 4 and a feed gas inlet.

[0063] Along the axial direction, the fluidized bed reactor is provided with 6 fluidized beds; the bottom of each fluidized bed is provided with an orifice 7-2.

[0064] An overflow pipe 7-1 is arranged between two adjacent fluidized beds, and the overflow pipe 7-1 is used to transport the catalyst particles in the upper layer of the adjacent two fluidized beds to the lower layer.

[0065] The lower part of the orifice plate 7-2 in the fluidized bed reactor is provided with an oxygen-containing gas inlet pipeline 2 .

[0066] The fluidized bed reaction device also includes a gas-solid separation device 5 arranged at the rear end of the product gas outle...

Embodiment 2

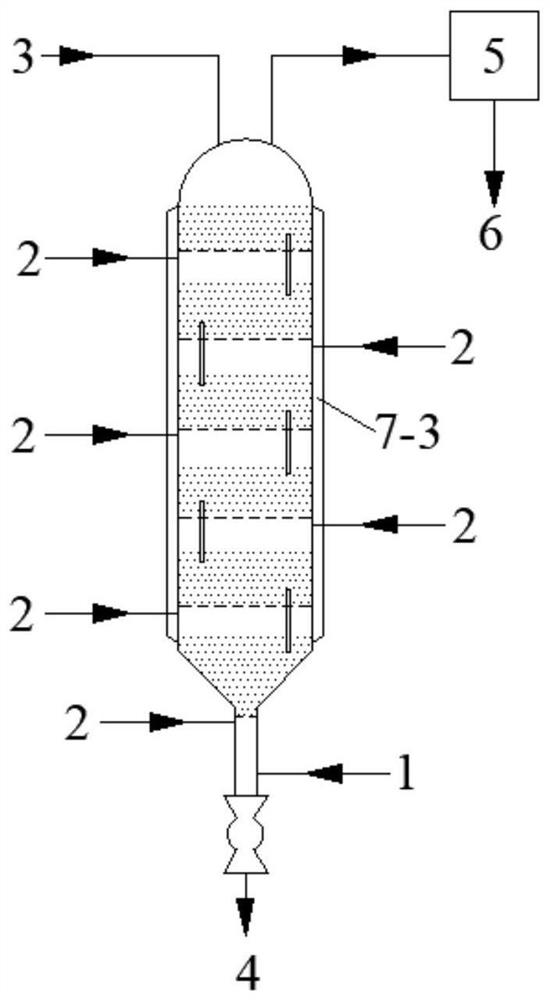

[0071] This embodiment provides a figure 2 The fluidized bed reaction device includes a fluidized bed reactor.

[0072] The top of the fluidized bed reactor is provided with a catalyst inlet and a product gas outlet.

[0073] The bottom of the fluidized bed reactor is provided with a catalyst outlet 4 and a feed gas inlet.

[0074] Along the axial direction, the fluidized bed reactor is provided with 6 fluidized beds; the bottom of each fluidized bed is provided with an orifice 7-2.

[0075] An overflow pipe 7-1 is arranged between two adjacent fluidized beds, and the overflow pipe 7-1 is used to transport the catalyst particles in the upper layer of the adjacent two fluidized beds to the lower layer.

[0076] The lower part of the orifice plate 7-2 in the fluidized bed reactor is provided with an oxygen-containing gas inlet pipeline 2 .

[0077] The fluidized bed reaction device also includes a gas-solid separation device 5 arranged at the rear end of the product gas outl...

Embodiment 3

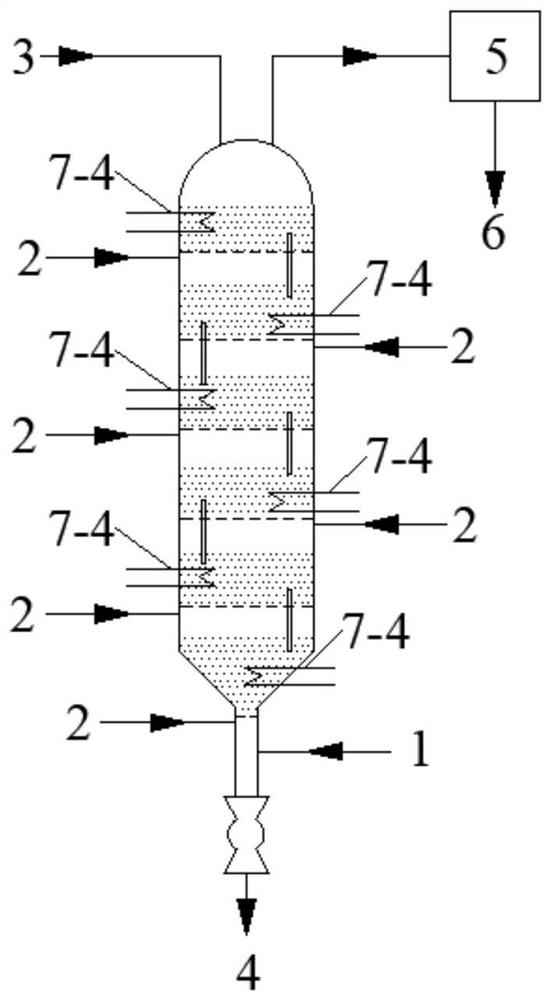

[0084] This embodiment provides a image 3 The fluidized bed reaction device includes a fluidized bed reactor.

[0085] The top of the fluidized bed reactor is provided with a catalyst inlet and a product gas outlet.

[0086] The bottom of the fluidized bed reactor is provided with a catalyst outlet 4 and a feed gas inlet.

[0087] Along the axial direction, the fluidized bed reactor is provided with 6 fluidized beds; the bottom of each fluidized bed is provided with an orifice 7-2.

[0088] An overflow pipe 7-1 is arranged between two adjacent fluidized beds, and the overflow pipe 7-1 is used to transport the catalyst particles in the upper layer of the adjacent two fluidized beds to the lower layer.

[0089] The lower part of the orifice plate 7-2 in the fluidized bed reactor is provided with an oxygen-containing gas inlet pipeline 2 .

[0090] The fluidized bed reaction device also includes a gas-solid separation device 5 arranged at the rear end of the product gas outle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com