Three-position three-way hydraulic change valve

A three-position three-way, water-hydraulic technology, which is applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., to achieve strict sealing, flexible spool movement, and reduced component costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

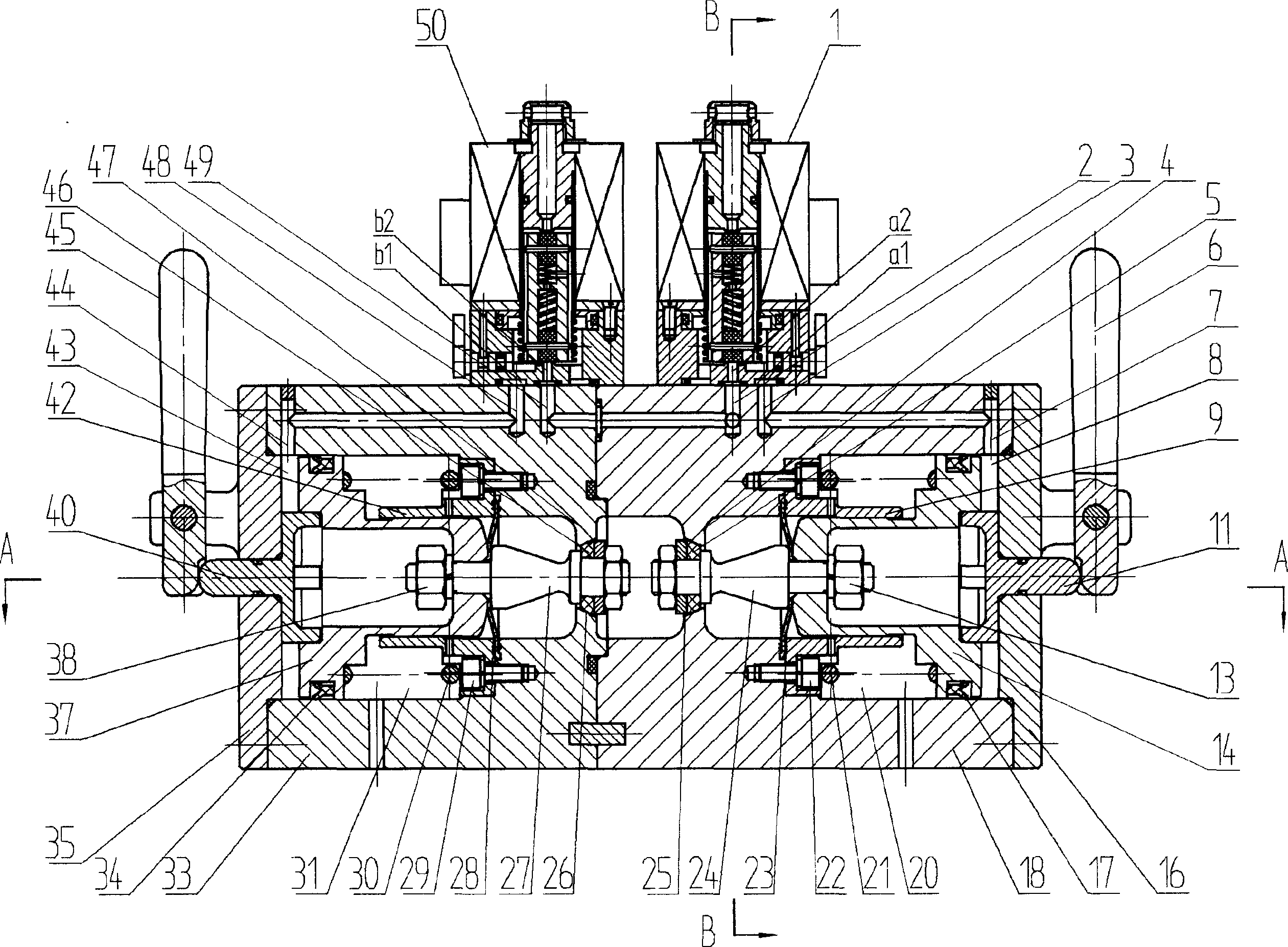

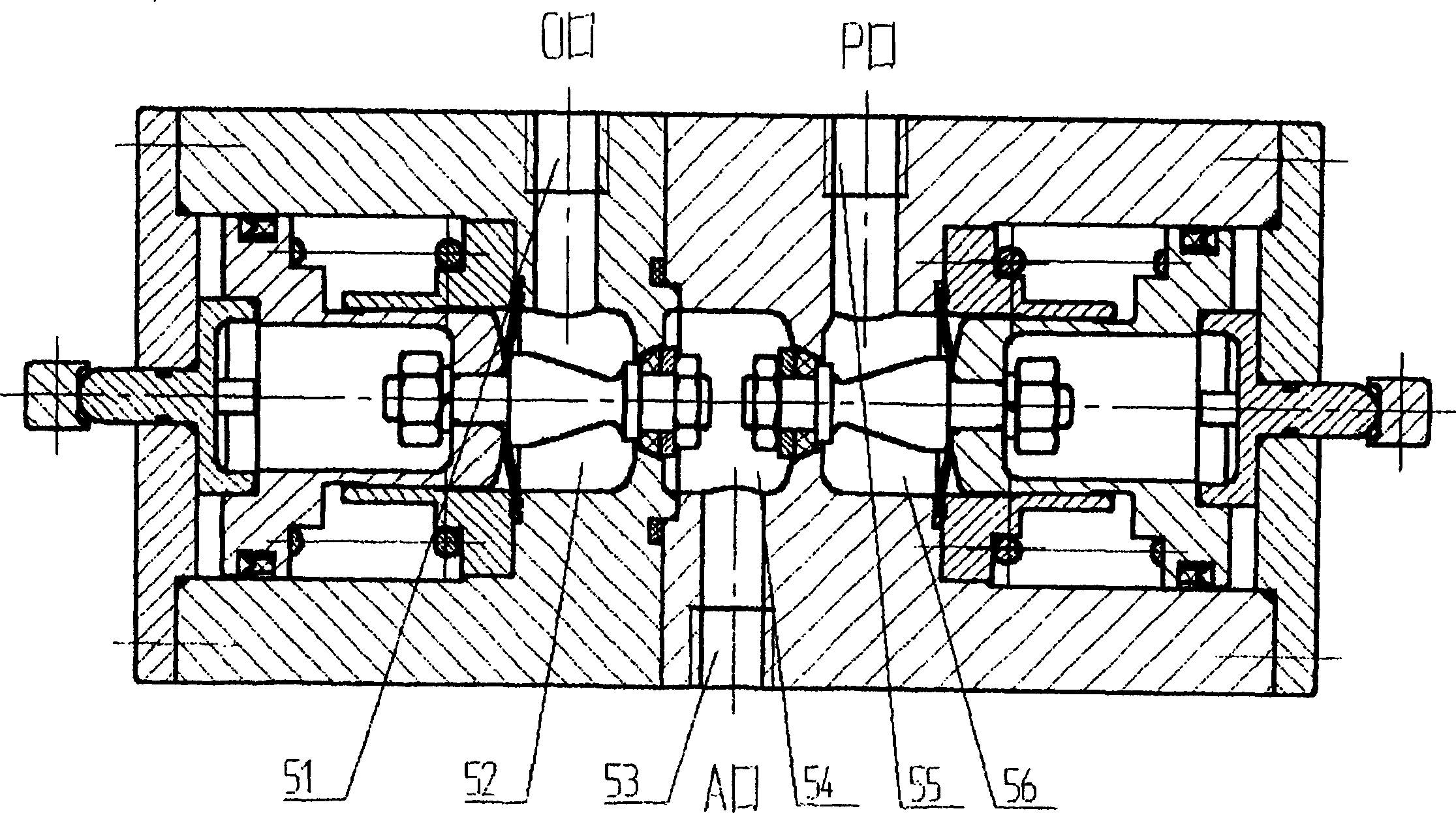

[0024] refer to Figure 1 ~ Figure 4 , the three-position three-way water hydraulic reversing valve that the present invention refers to is formed by the docking of left and right two substantially identical inverted cone valves.

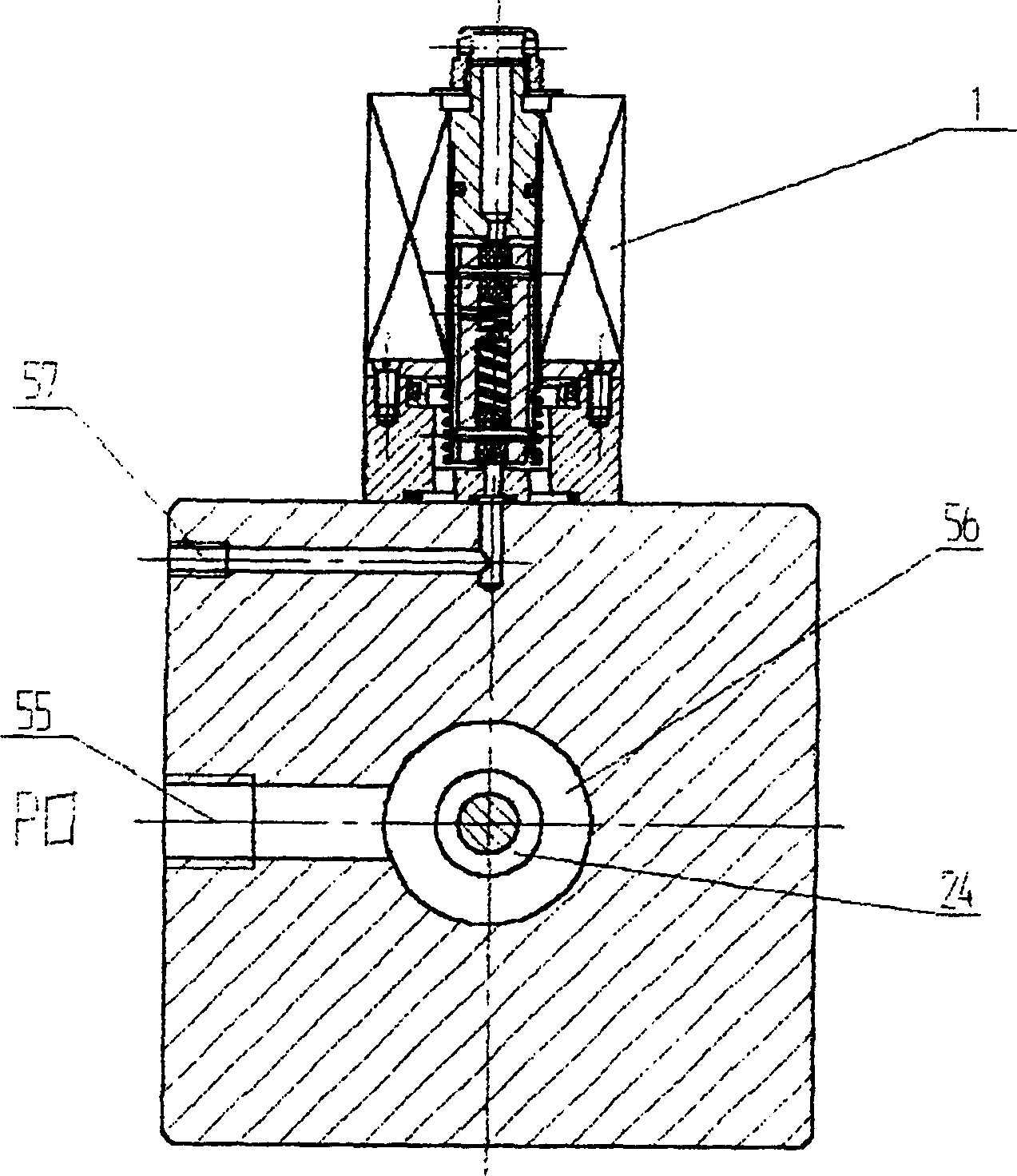

[0025] The right inverted cone valve is composed of electromagnetic pilot valve 1, handle 6, cylinder piston guide sleeve 9, handle rod 11, cylinder piston 14, end cover 16, valve body 18 with inverted cone valve seat 4 and cylinder chamber 20, reset Spring 21, corrugated rubber diaphragm 23, spool 24 with tapered gasket 5, water pressure inlet port (P port) 55, water pressure outlet port (A port), air source inlet port 57 constitute. The cylinder piston guide sleeve 9 is installed in the valve body 18 by the screw 22, and guides the movement of the cylinder piston 14; the cylinder piston 14 and the cylinder piston return spring 21 are installed in the cylinder cavity 20, and the Y-shaped sealing ring 17 is installed on the cylinder piston 14; The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com