Method for testing boiling shrinkage of high shrinkage polyester fiber

A boiling water shrinkage, filament boiling water technology, applied in textile testing, material inspection products, etc., can solve the problems of high shrinkage fiber evaluation deviation, negative impact of subsequent processed products, etc., to achieve fast evaluation speed, high accuracy, good boiling water The effect of shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

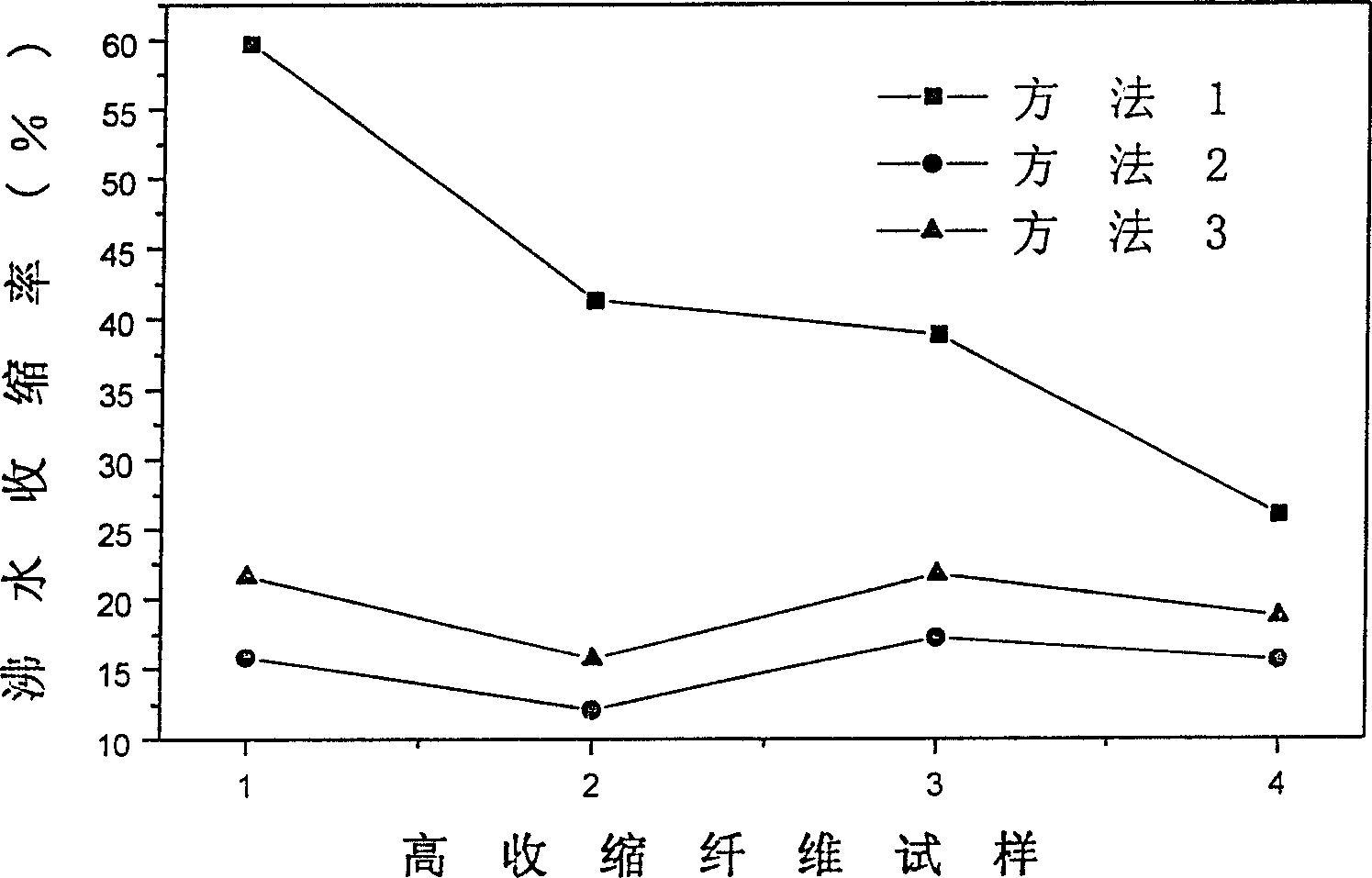

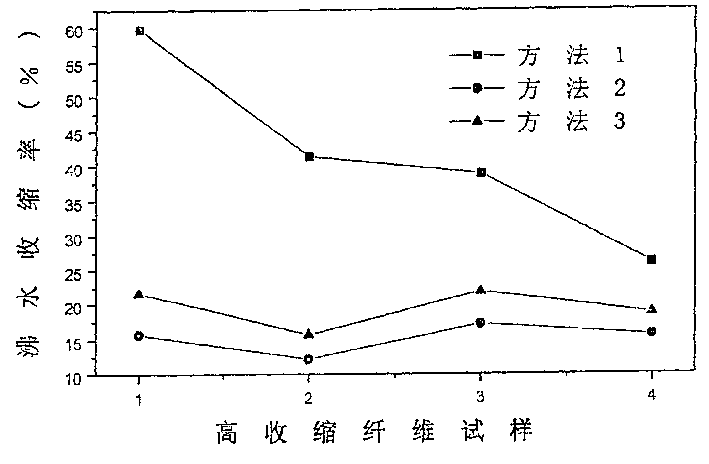

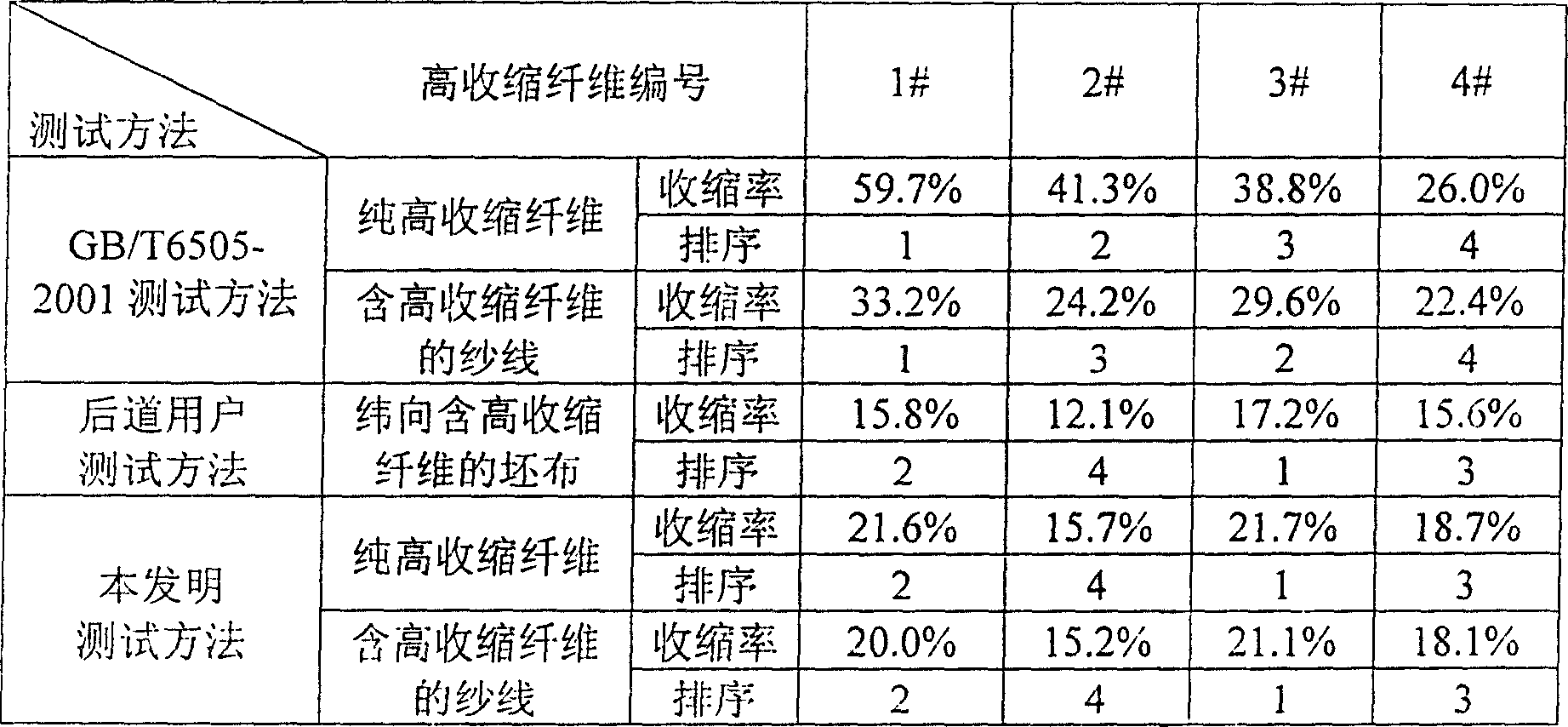

Embodiment 1

[0019] The high-shrinkage polyester FDY filament and the yarn containing the filament are respectively processed on the bobbin frame to make a skein, and carried out for 2 hours under the conditions of standard atmospheric pressure, 18-22 °C, and relative humidity of 62-68%. Equilibrium before heat treatment above. Measure the respective length L before boiling 0 , then put into a mesh bag. When the water temperature is 40°C, immerse the mesh bag containing the sample into the water, raise the water temperature to 100°C at a rate of 1.7°C / min, keep boiling for 30 minutes, then take out the mesh bag and boil it Blot the sample with absorbent paper, dry the sample at 50-60°C and no external tension for 60-90 minutes, and then in a relaxed state at standard atmospheric pressure, 18-22°C, relative humidity Under the condition of 62-68%, the sample is subjected to equilibrium treatment for more than 2 hours, and the length L of the sample after boiling is measured S , according ...

Embodiment 2

[0021] Use the same batch of samples as in the example, except that the temperature of the water medium when it is put into the mesh bag containing the sample is 30°C, the heating rate of the water is 4.3°C / min, and the time to maintain the boiling state is 35 minutes. Except for a change of conditions, other testing process and conditions are the same as in Example 1, and the boiling water shrinkage rate of the high-shrinkage polyester FDY filament sample is 22.3%, and the boiling water shrinkage rate of the yarn sample containing the high-shrinkage polyester FDY filament The rate is 20.5%.

Embodiment 3

[0023] With the sample of the same batch as in the embodiment, except that the aqueous alkali solution is used as the heating medium, the temperature of the water is 50°C when the mesh bag containing the sample is added, the heating rate of the water is 1.2°C / min, and the boiling state is maintained. Time is 25 minutes except that four conditions are changed, other test process and conditions are identical with embodiment one, obtain the boiling water shrinkage rate of this high-shrinkage polyester FDY filament sample 22.6%, the yarn containing this high-shrinkage polyester FDY filament The boiling water shrinkage of the sample was 20.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com