Hand tool, in particular a screwdriver

A hand tool and tool technology, applied in the field of screwdriver or a wrench, thread tool, clamping tool or file, pliers, can solve the problems of wear and tool brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

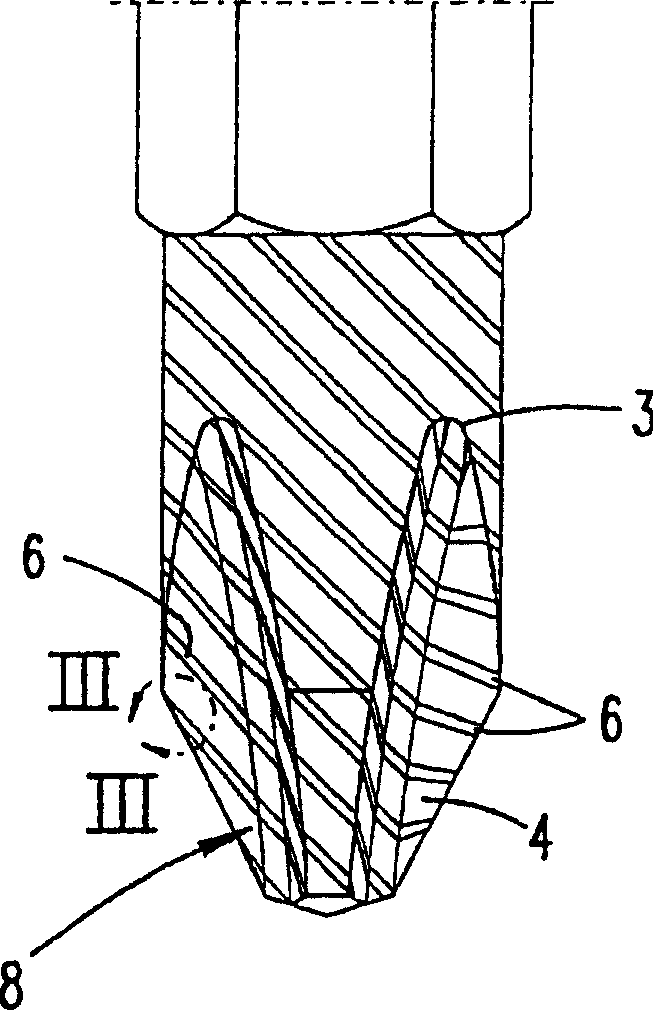

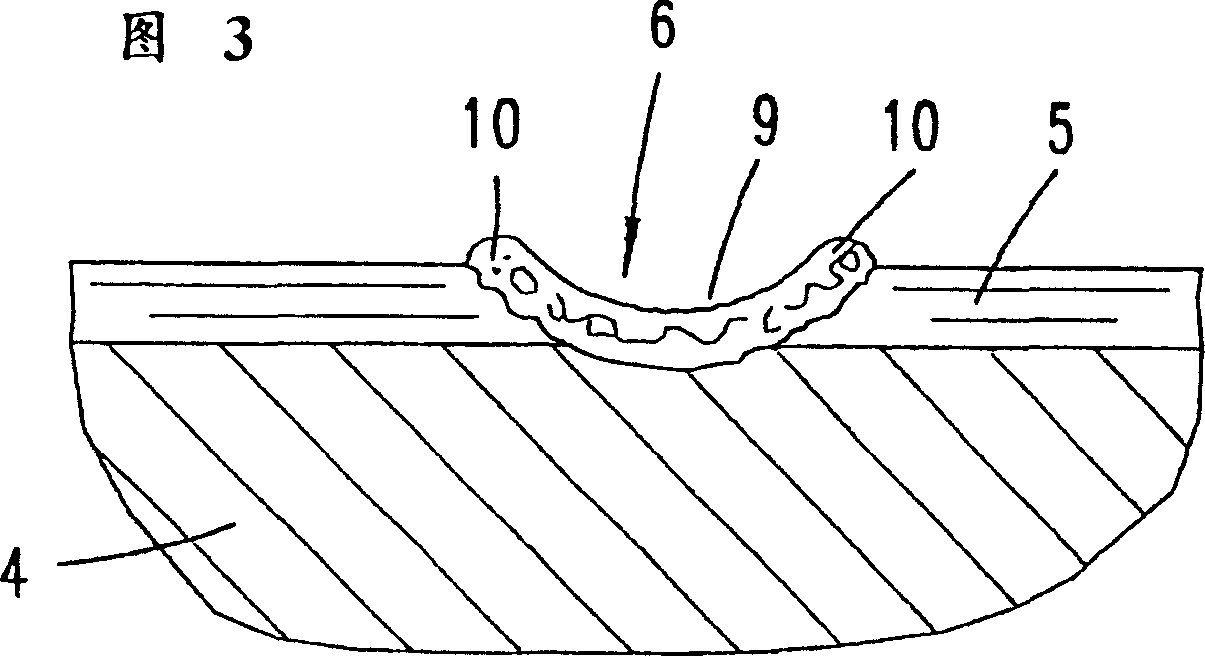

[0028] figure 1 with 2 The exemplary embodiment shown in is a screwdriver having a handle 1 and a blade 2 . At its end, the blade 2 has a working tip 3 . The working tip 3 forms a workpiece interface 8 . In this exemplary embodiment, the latter is in the shape of a cross. A plurality of parallel laser beams passing through the workpiece bonding surface 8 produces a plurality of linear contour fringes 6, which extend parallel to each other. The metal coating 5 applied to the steel core 4 serves to increase the strength of the material. This increase in the strength of the material in the region of the joining profile 6 of the material is accompanied by an increase in the surface hardness by approximately 100%. The energized region 6 is formed slightly further back than the non-energized region surrounding it. Application of the laser beam causes the melt to form along the path of the laser beam. Since the melt has a very high temperature gradient with respect to the bill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com