Patents

Literature

32 results about "High energy irradiation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Changing surface properties by functionalized nanoparticles

InactiveUS20100178512A1Strong and durable adhesionMaterial nanotechnologyPretreated surfacesFunctionalized nanoparticlesUltraviolet

A process for modifying the surface of an inorganic or organic substrate with strongly adherent nanoparticles is described, providing to the surface modified substrate durable effects like hydrophobicity, hydrophilicity, electrical conductivity, magnetic properties, flame retardance, color, adhesion, roughness, scratch resistance, UV-absorbance, antimicrobial properties, antifouling properties, antiprotein properties, antistatic properties, antifog properties, release properties. In this process, an optional first step a) a low-temperature plasma, ozonization, high energy irradiation, corona discharge or a flame is caused to act on the inorganic or organic substrate, and in a second step b) one or more defined nanoparticles or mixtures of defined nanoparticles with monomers, containing at least one ethylenically unsaturated group, or solutions, suspensions or emulsions of the afore-mentioned substances, are applied, preferably at normal pressure, to the inorganic or organic substrate. In a third step c) suitable methods are applied to dry or cure those afore-mentioned substances and, optionally, in a fourth step d) a further coating is applied on the substrate so pretreated.

Owner:CIBA CORP

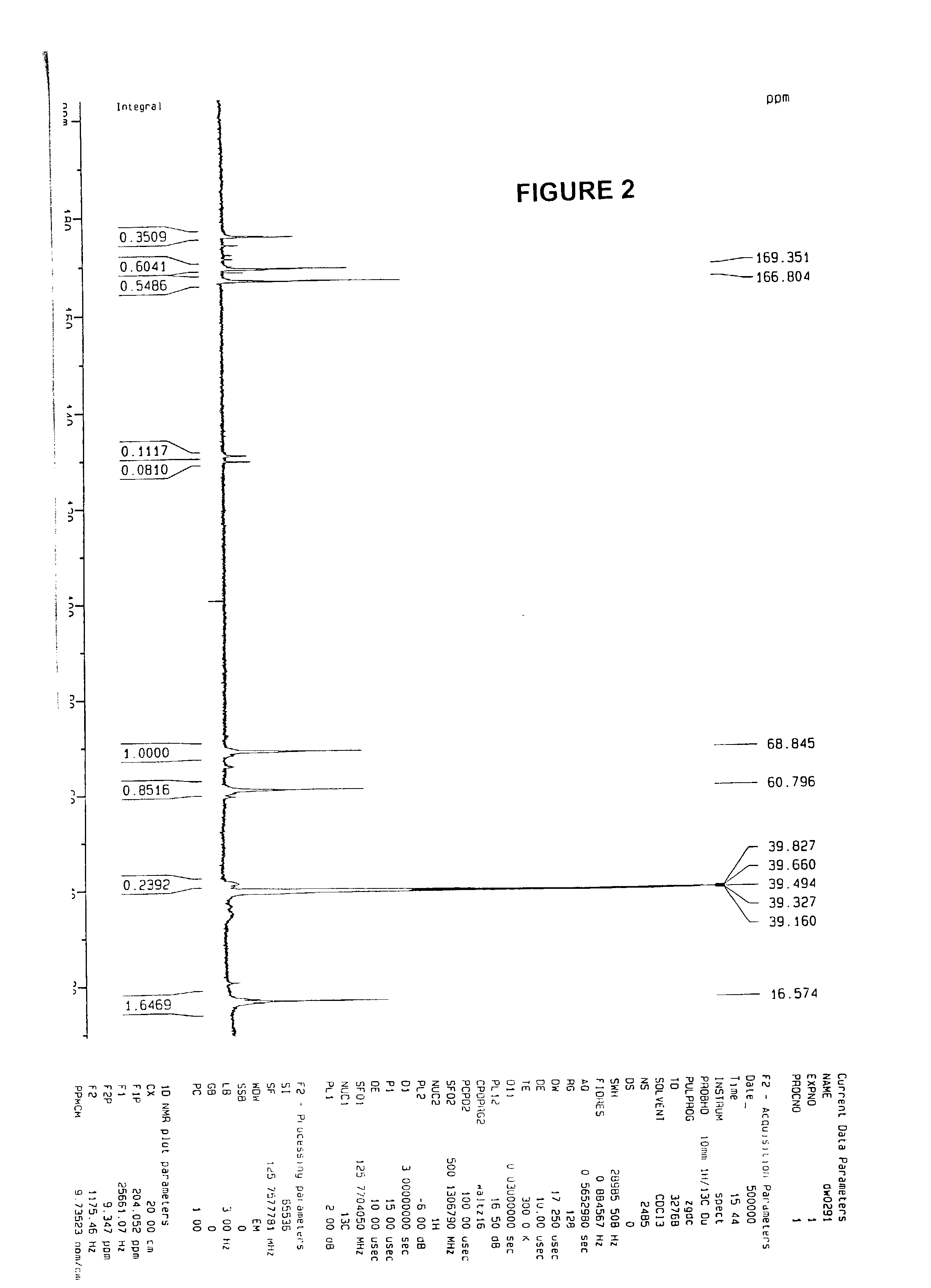

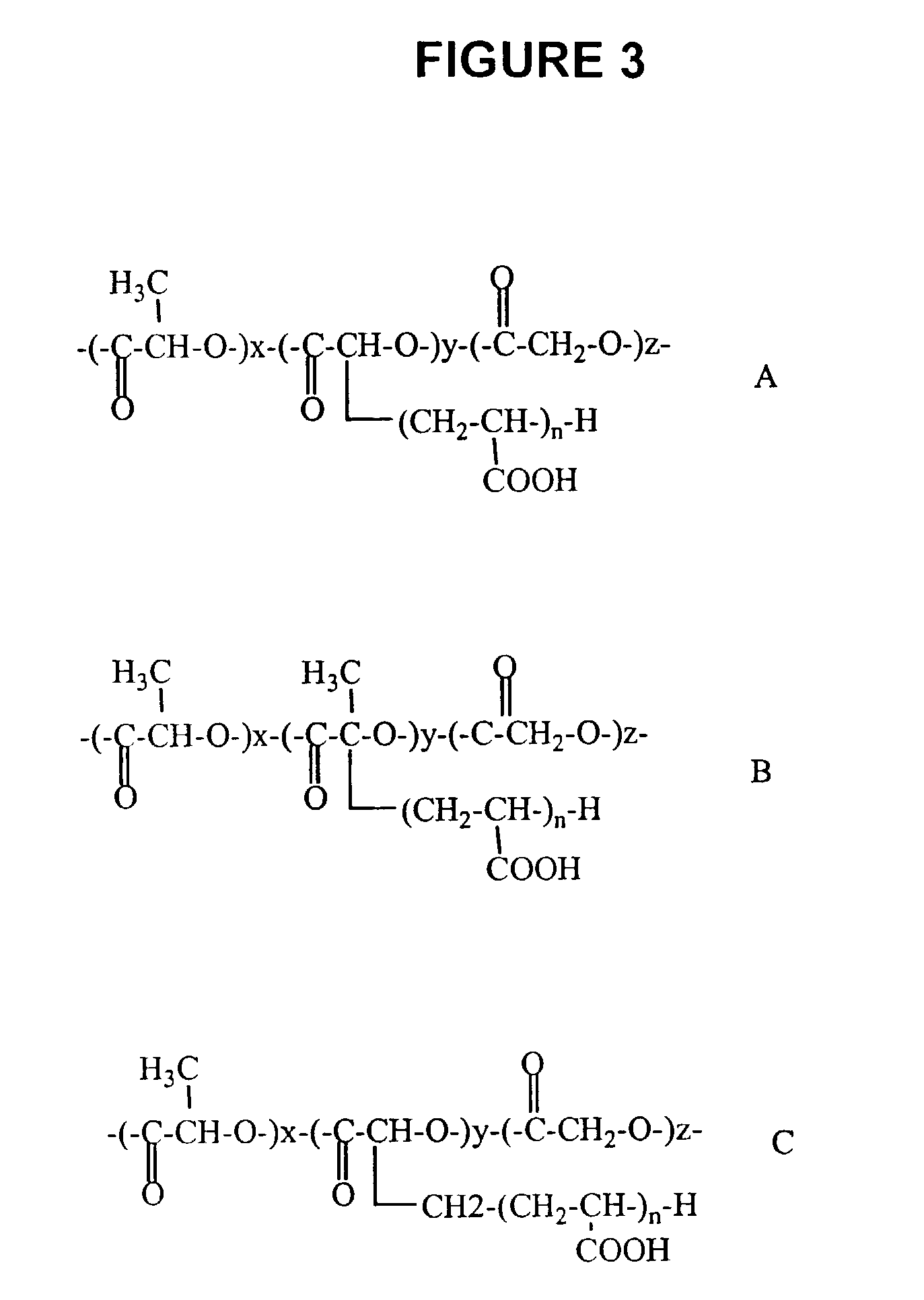

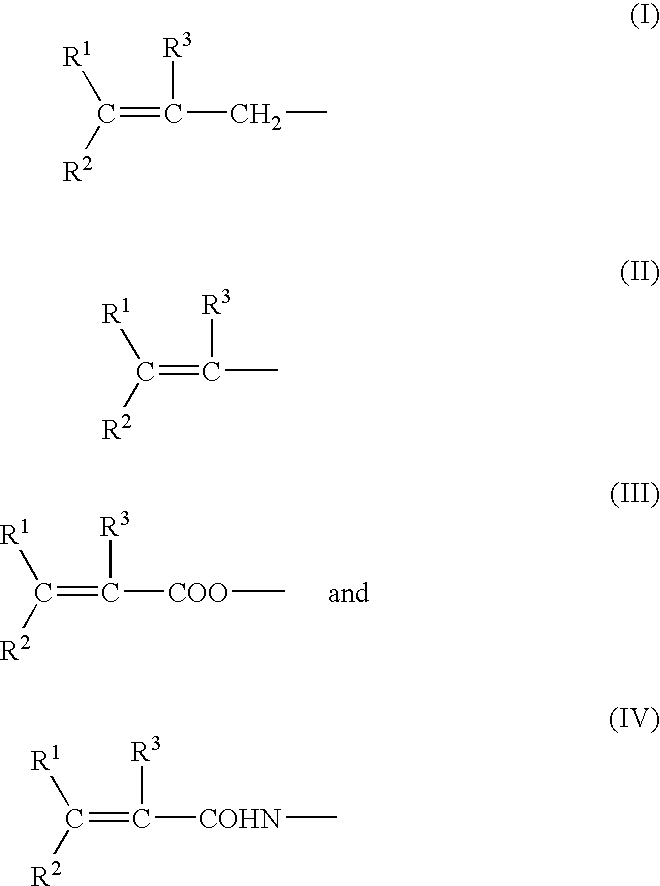

Methods of making functional biodegradable polymers

There is provided a method to modify biodegradable polymers using the direct reaction of a biodegradable polymer in a vinyl monomer and may take place in the presence of initiators. The initiator may be free radical initiators, heat, ionic initiators, UV irradiation, ionizing irradiation and other high energy irradiation. Suitable biodegradable polymer include polycaprolactone, poly(lactic acid), poly(glycolic acid) and poly(lactic-co-glycolic acid). Suitable vinyl monomers include acrylates, methacrylates and the like.

Owner:KIMBERLY-CLARK WORLDWIDE INC

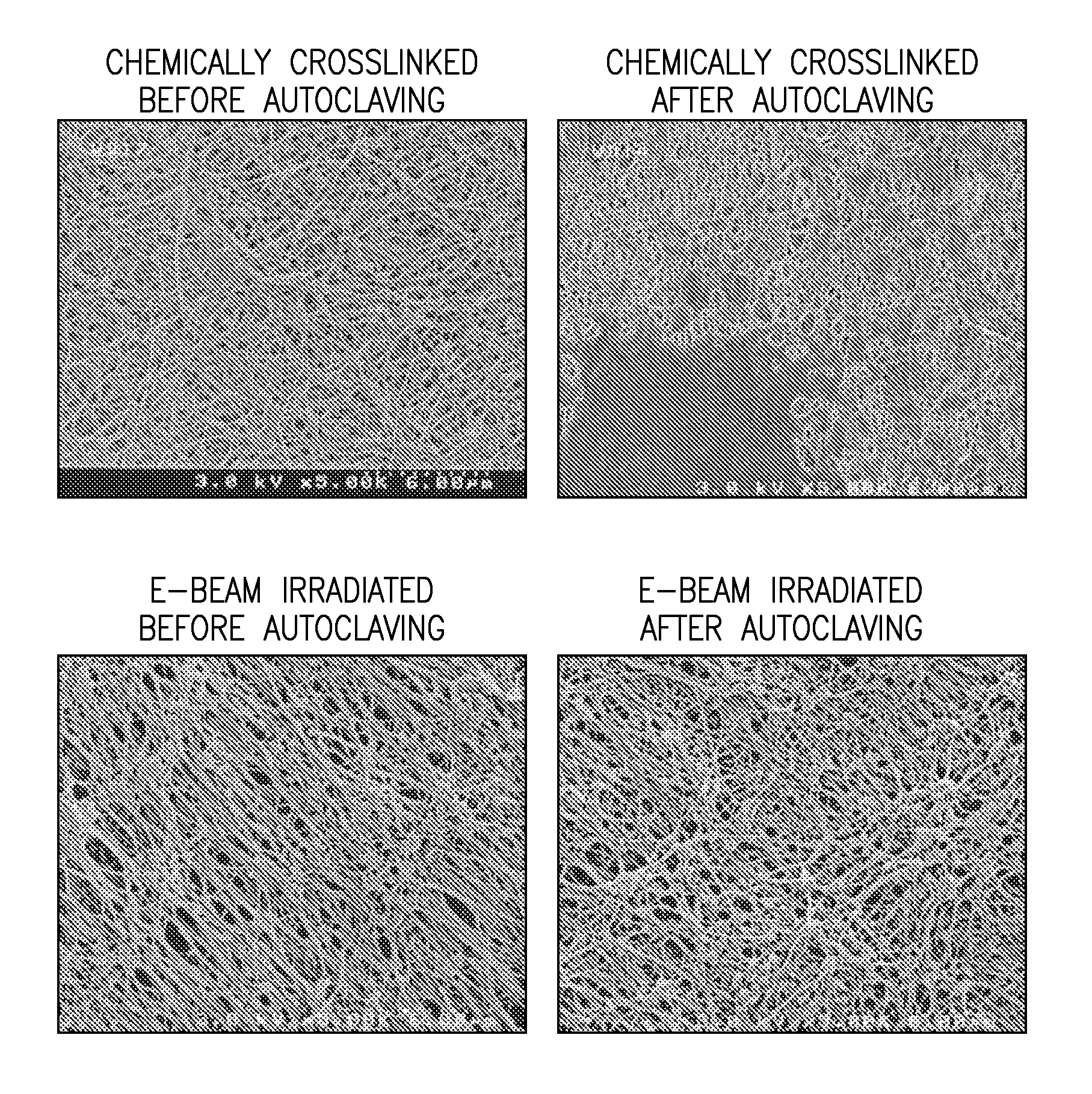

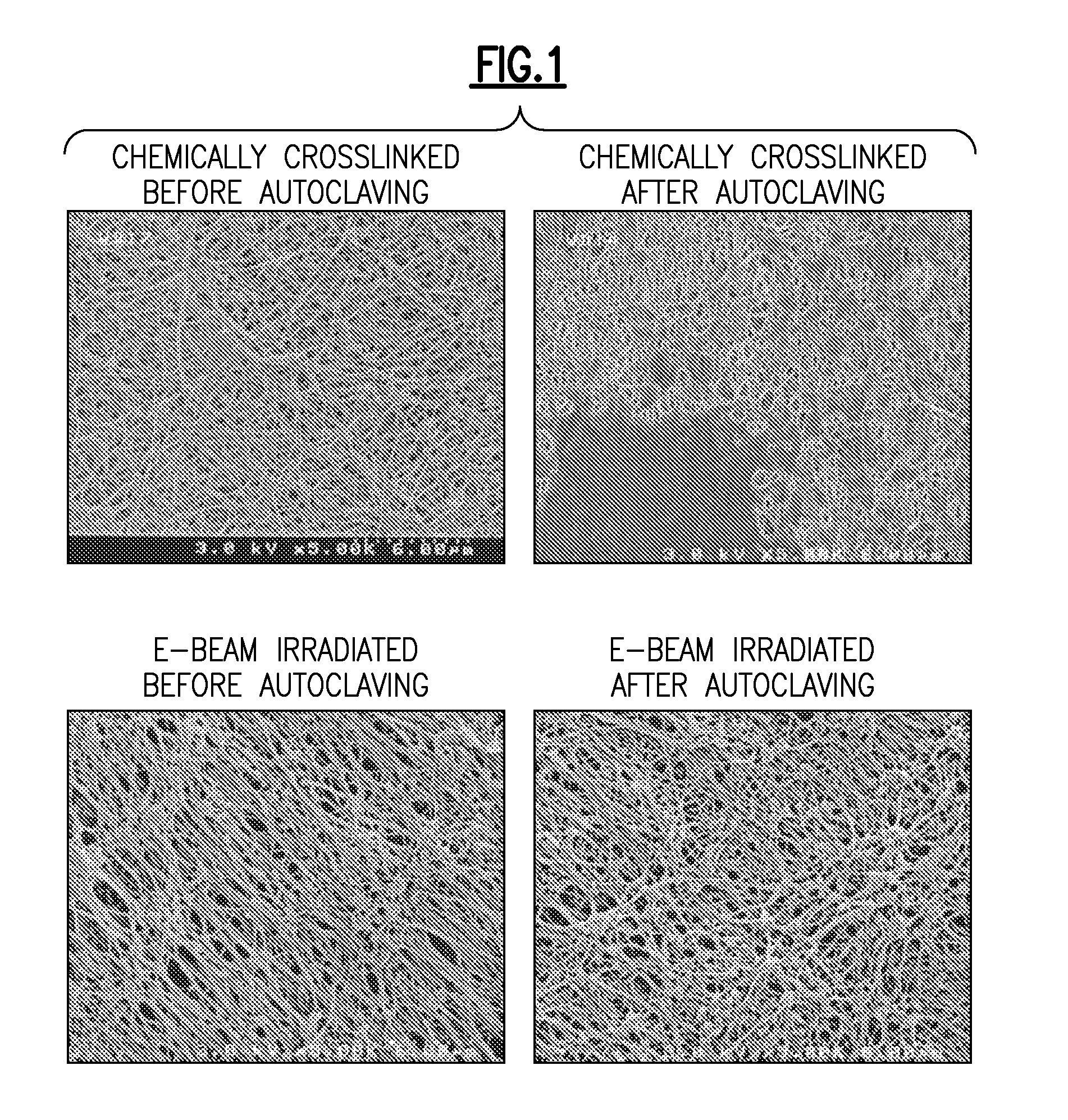

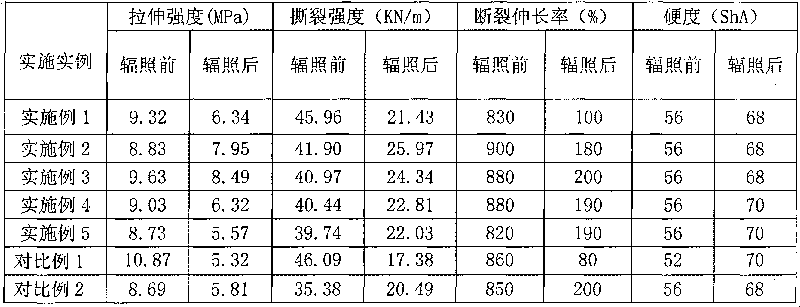

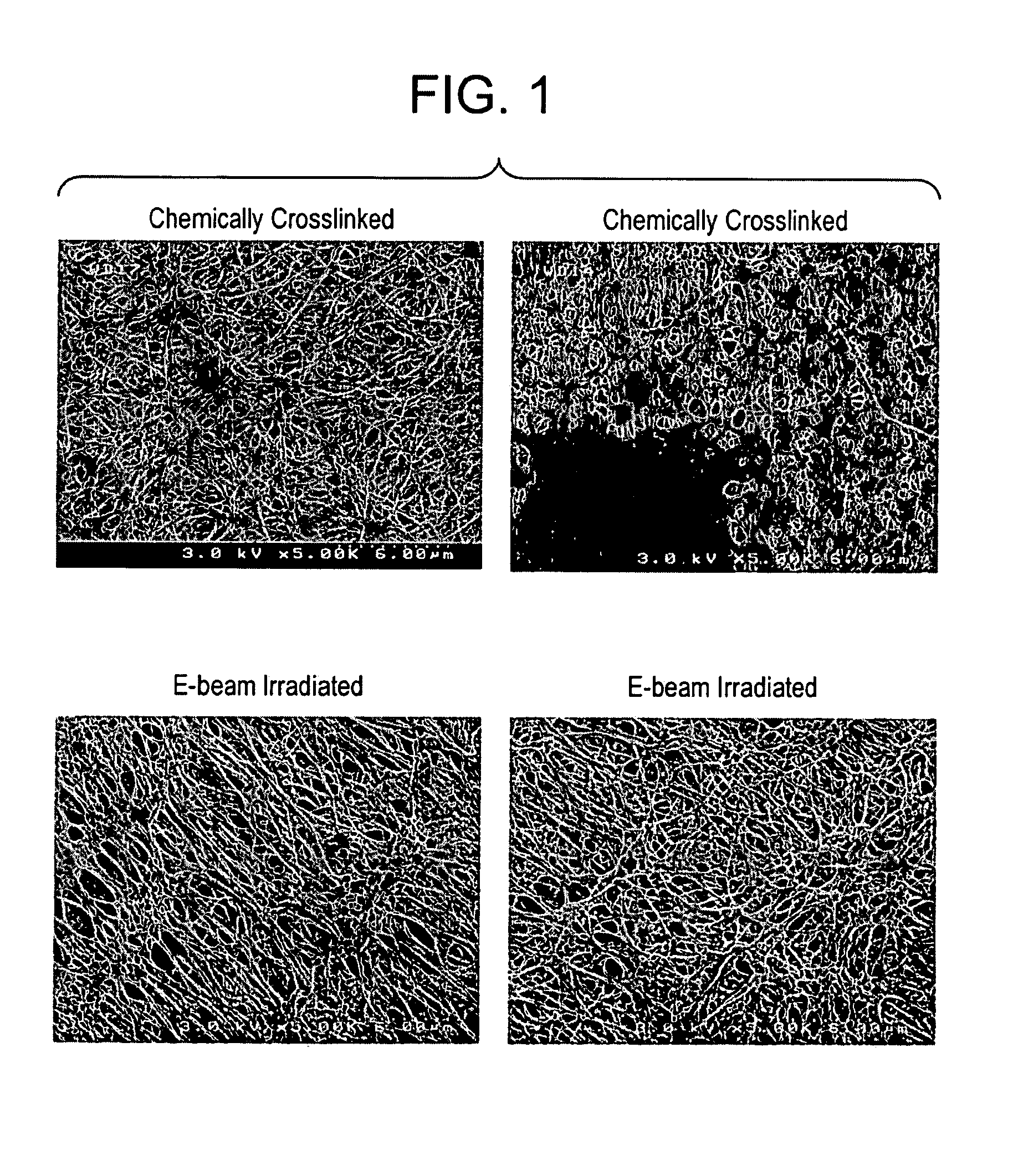

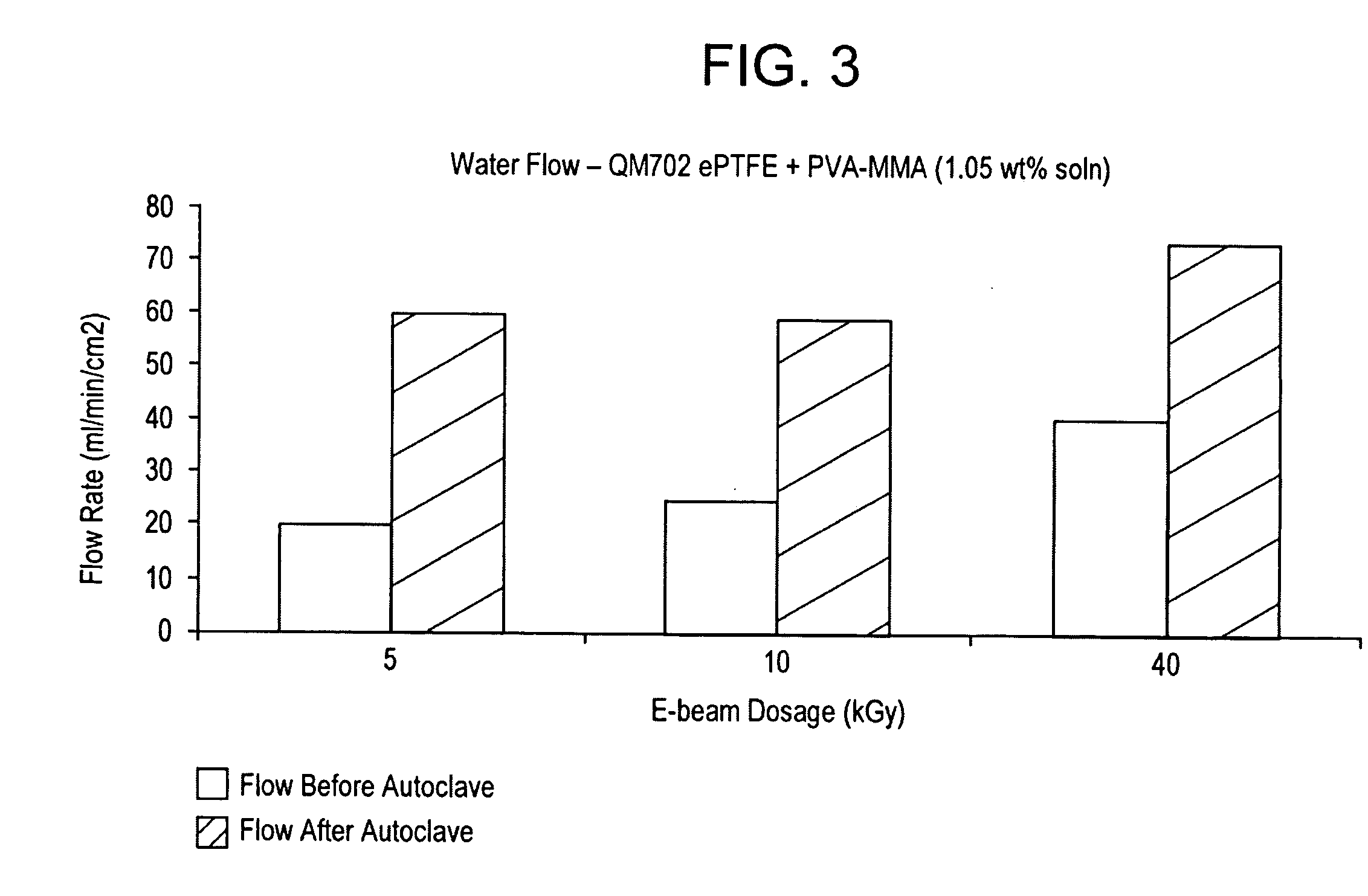

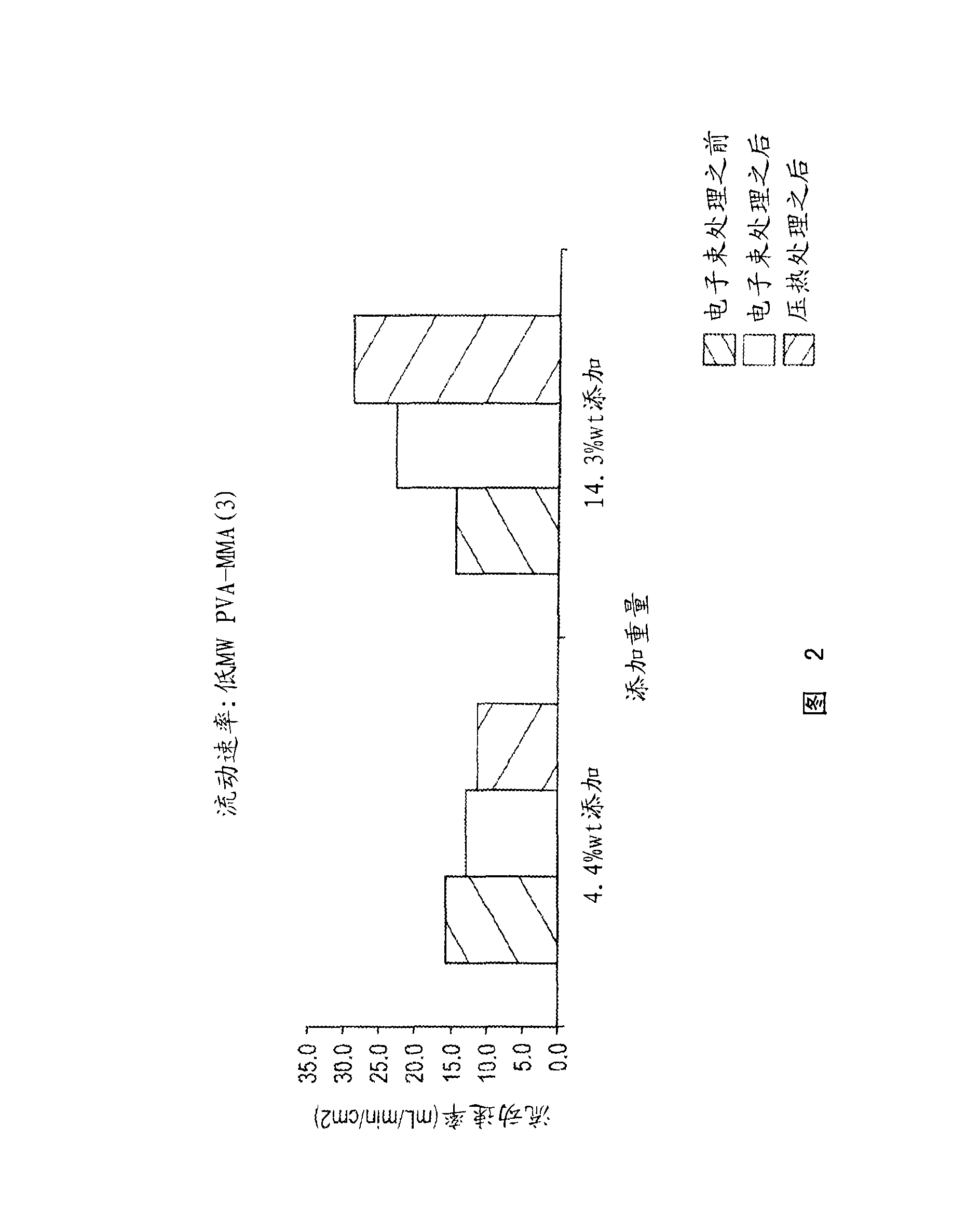

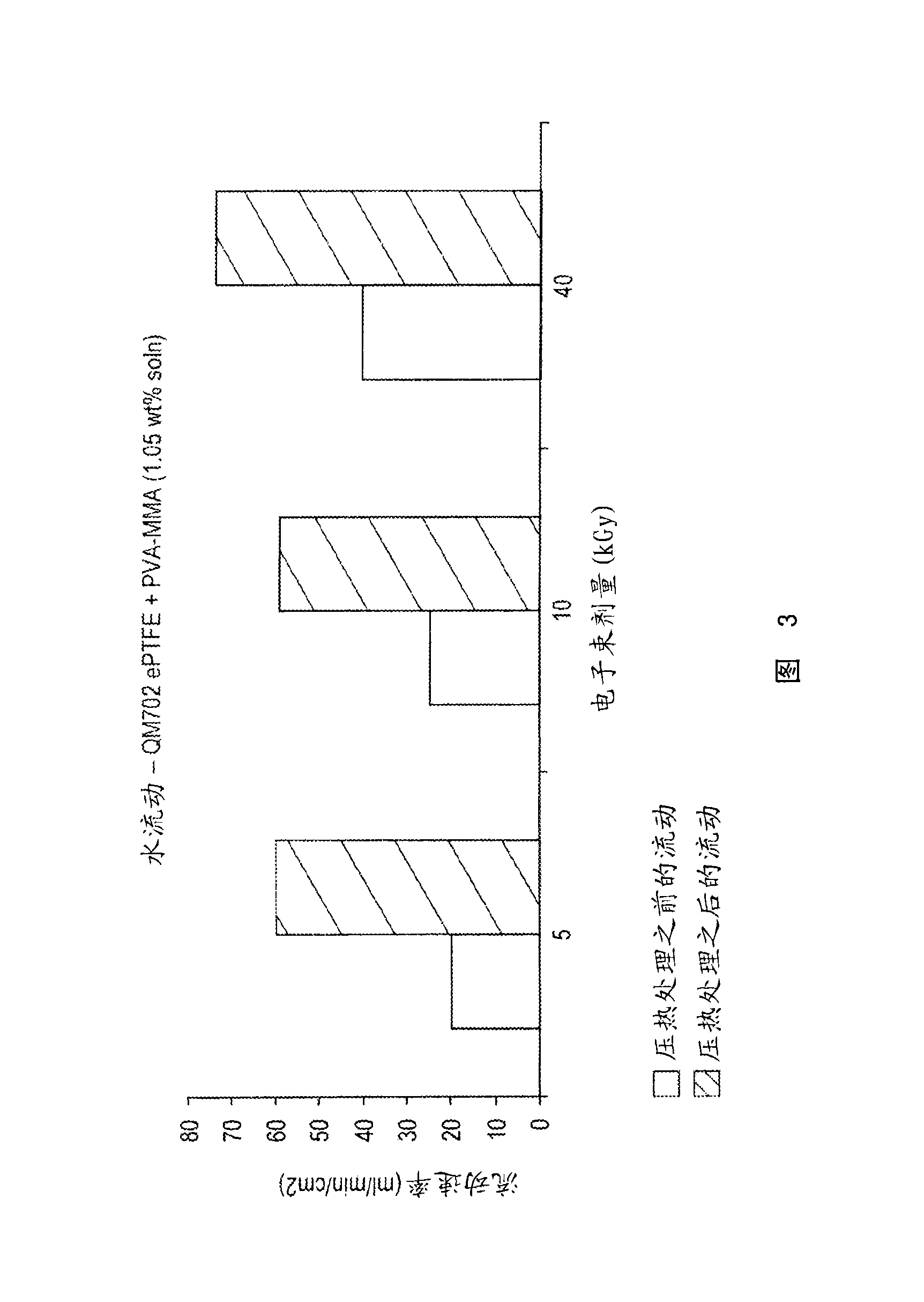

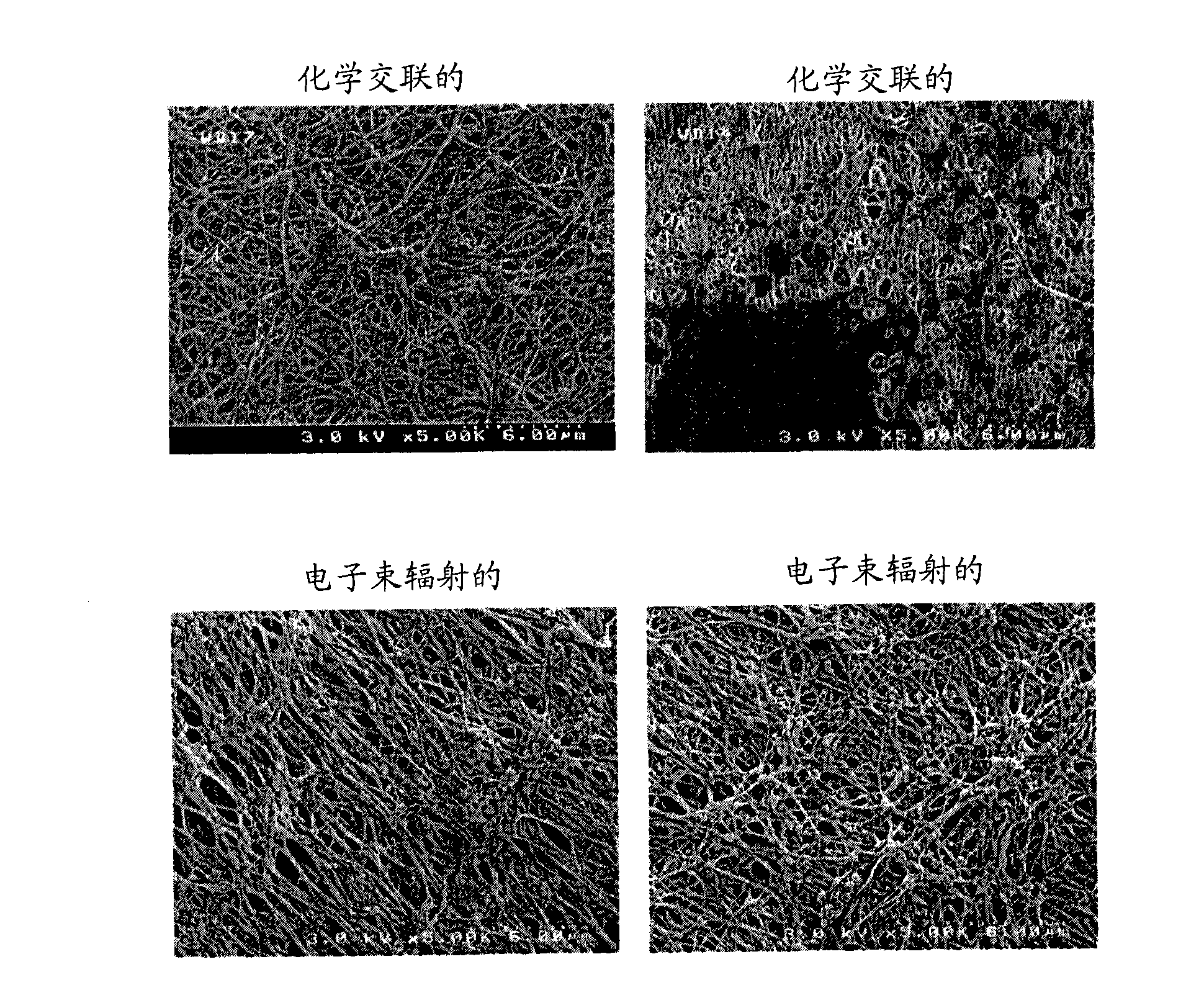

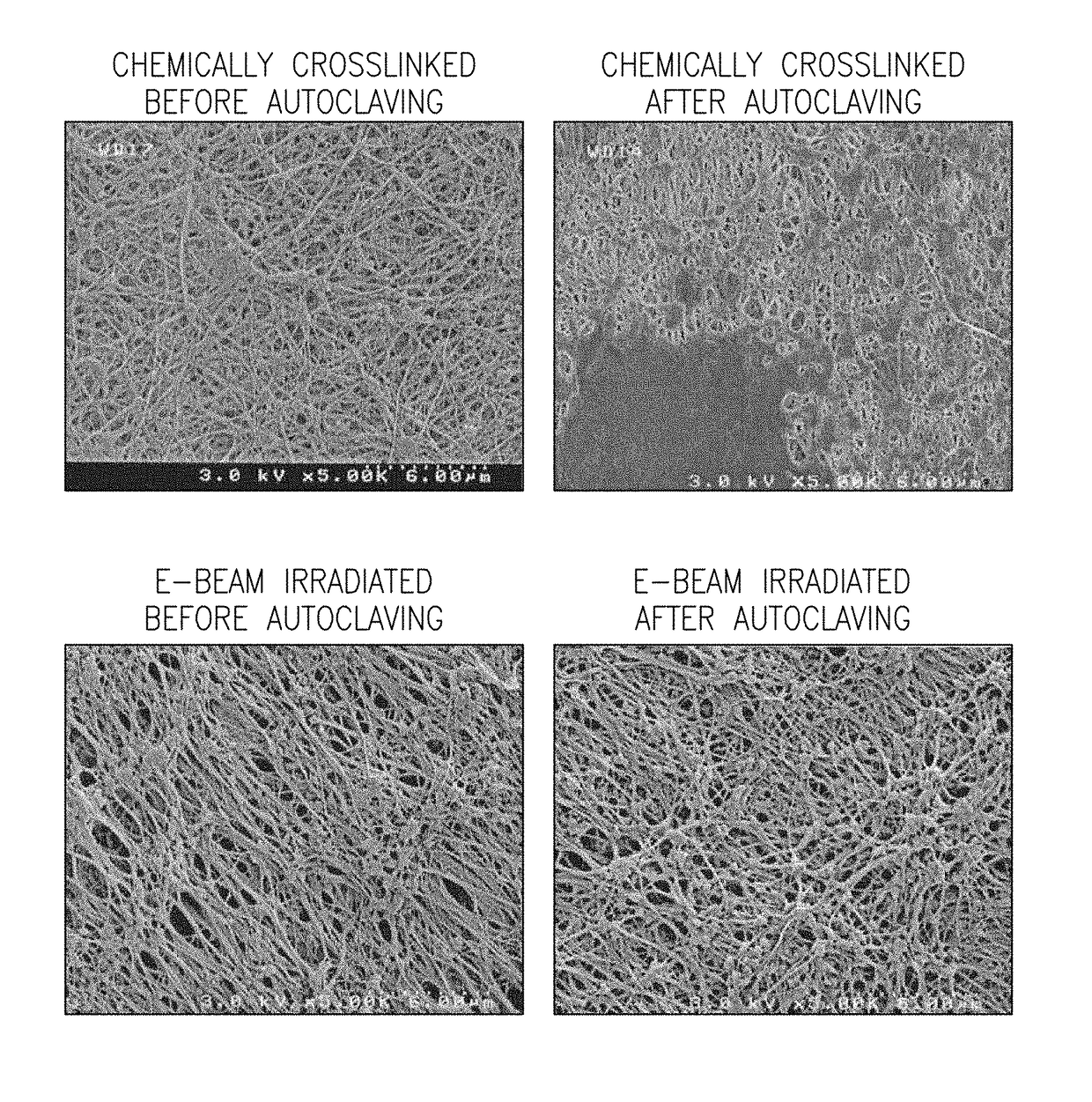

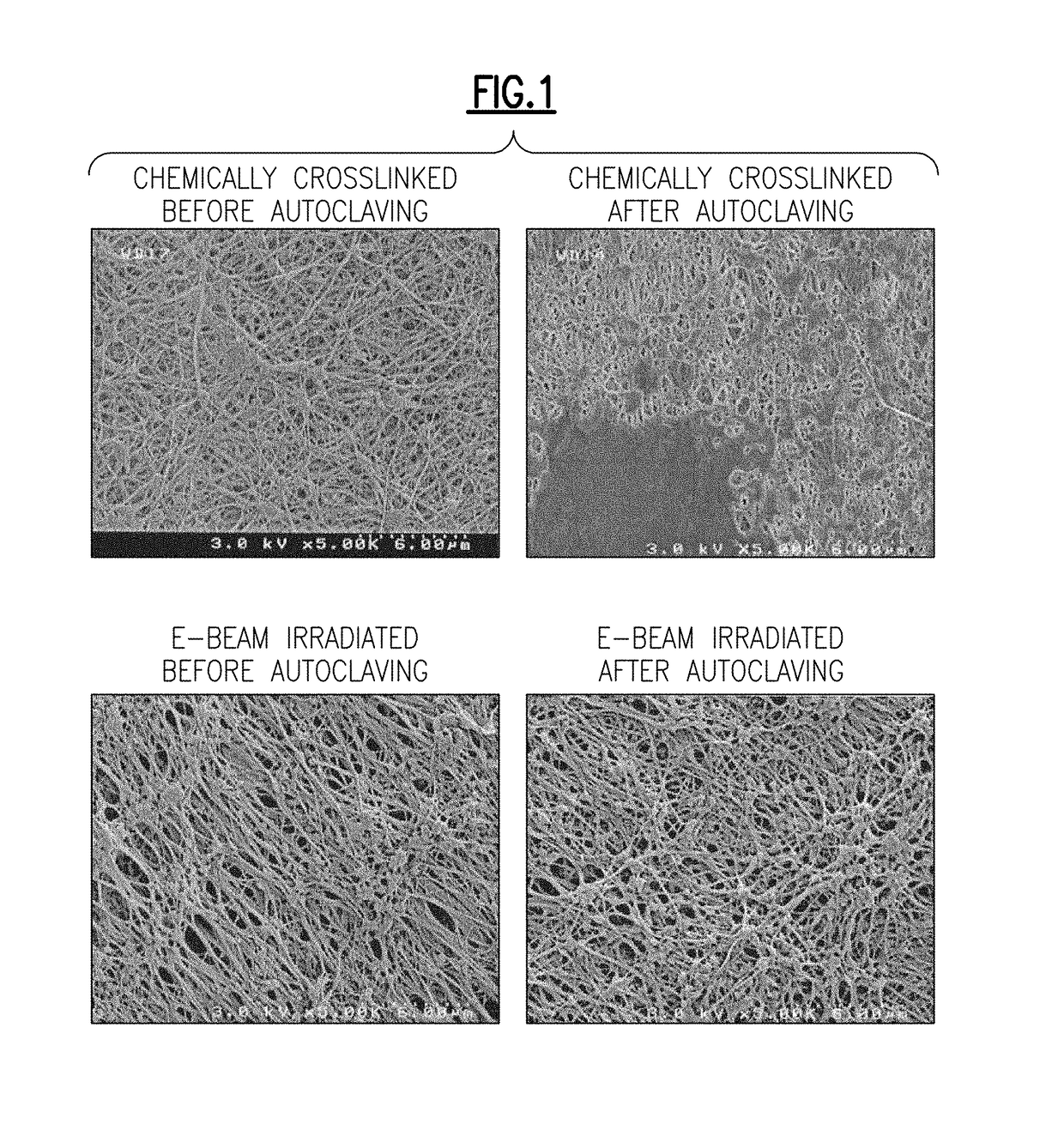

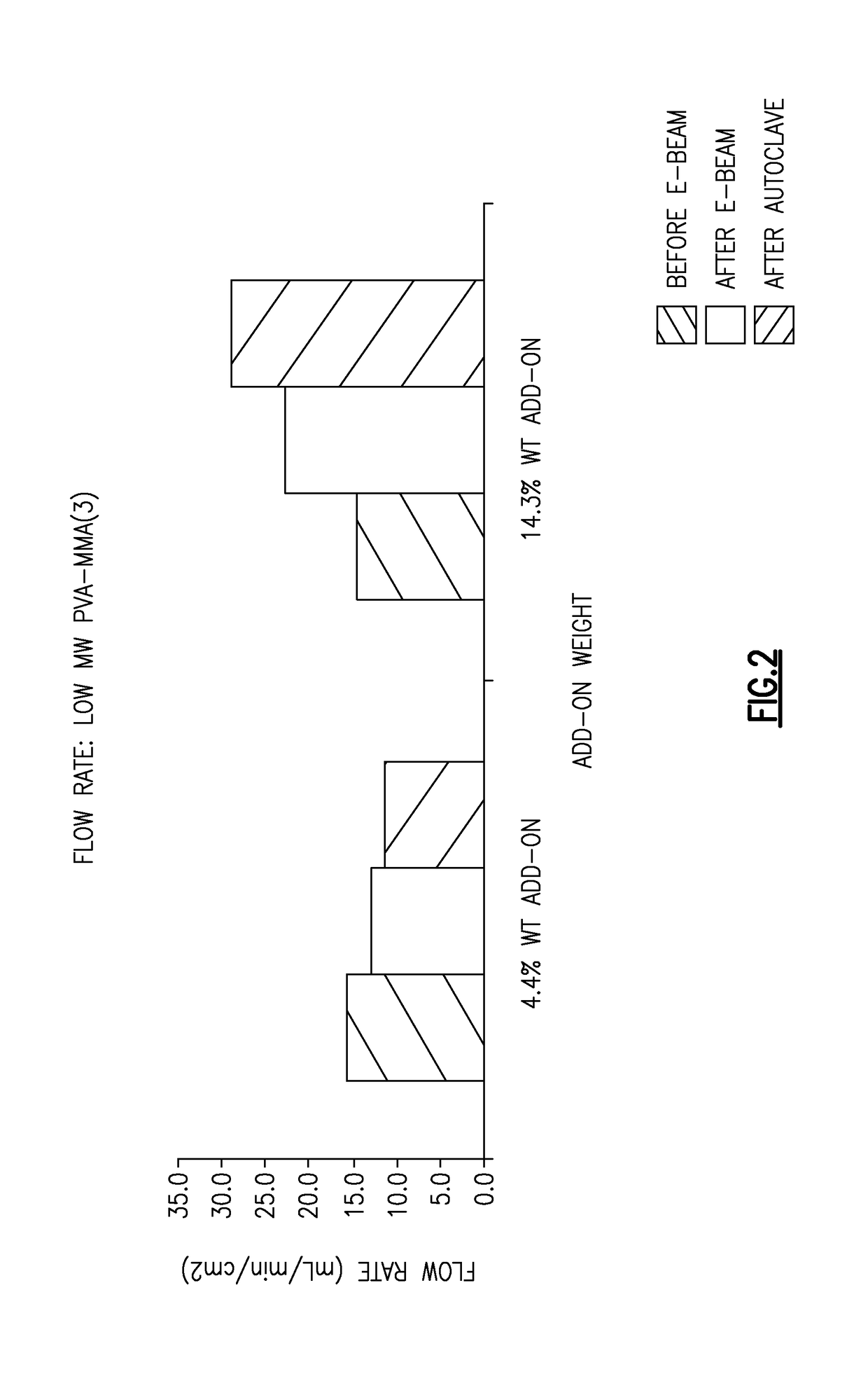

Permanent hydrophilic porous coatings and methods of making them

A membrane includes a porous base membrane and a hydrophilic coating. The coating comprises a hydrophilic additive and a hydrophilic polymer derivatized with an electron beam reactive group adapted to form a radical under high energy irradiation. In some embodiments, the membrane comprises a fluoropolymer. Also disclosed are processes for forming the membrane.

Owner:PARKER HANNIFIN CORP

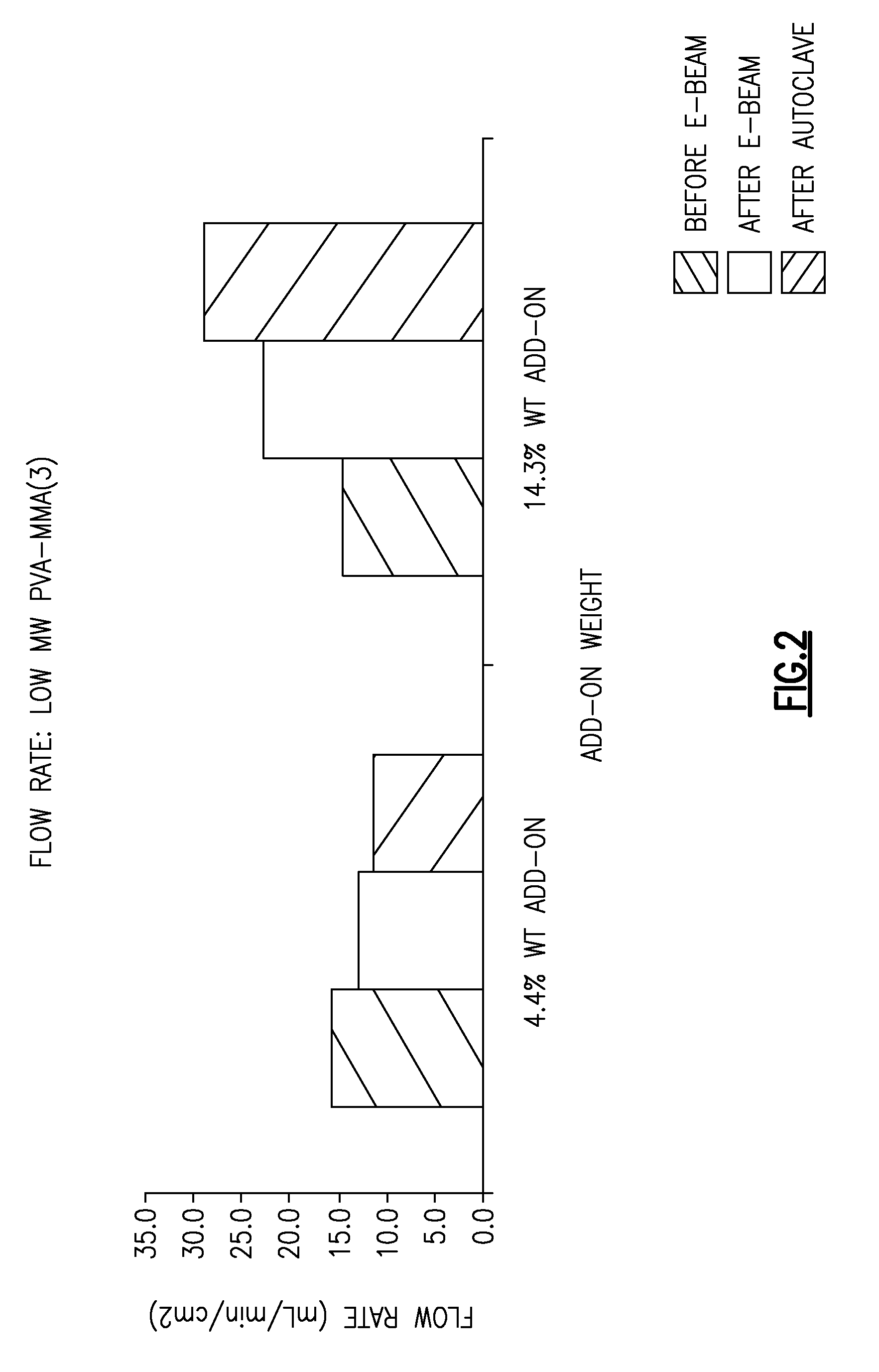

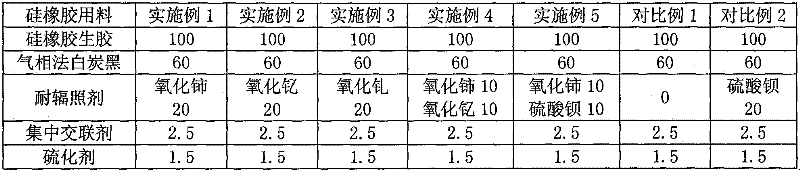

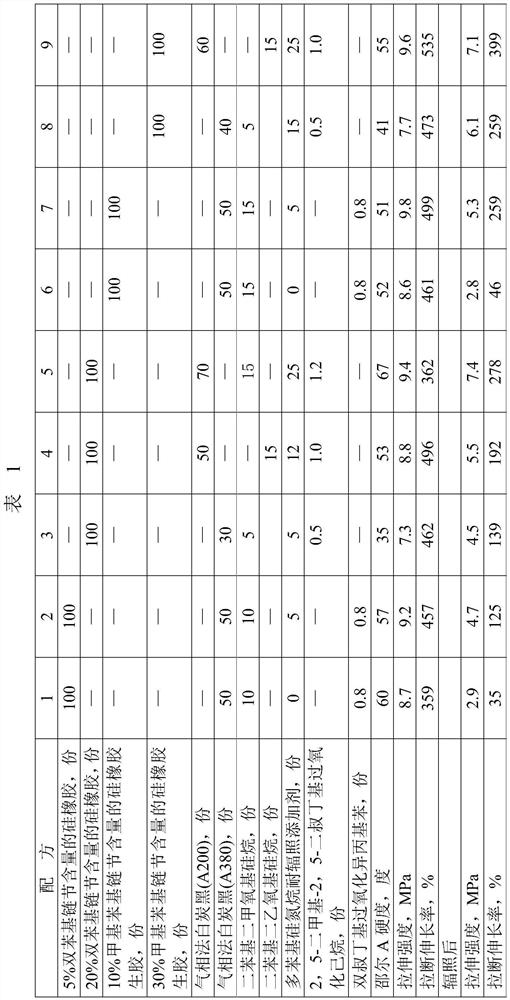

Peroxidated heat-vulcanized silicone rubber resistant to irradiation and preparation method thereof

ActiveCN101717581AImprove radiation resistanceImprove mechanical propertiesChemical industryPolymer science

The invention discloses a peroxidated heat-vulcanized silicone rubber resistant to irradiation and a preparation method thereof. The peroxidated heat-vulcanized silicone rubber comprises 100 parts of silicon rubber, 10-60 parts of anti-irradiation agent, 40-70 parts of gaseous white carbon black, 2-7 parts of concentrated crosslinker and 0.5-2.5 parts of vulcanizing agent according to parts by weight. The peroxidated heat-vulcanized silicone rubber resistant to irradiation is prepared from a main material of methyl vinyl silicon rubber by modification; the rubber has strong environmental suitability, and the stretch strength reaches more than 6MPa and the tear strength reaches more than 20KN / m after 500KGy of irradiation; the rubber can be used for producing various rubber products resistant to irradiation such as rubber cushions, sealing parts, buffer elements, distance sleeves, diaphragms, and can be widely applied to the conditions abundant in high-energy irradiation such as aerospace, nuclear industry, electronic communication, chemical industry, medicine and ship; thus, the rubber has very good economic benefit and promotional value.

Owner:SHANDONG UNIV

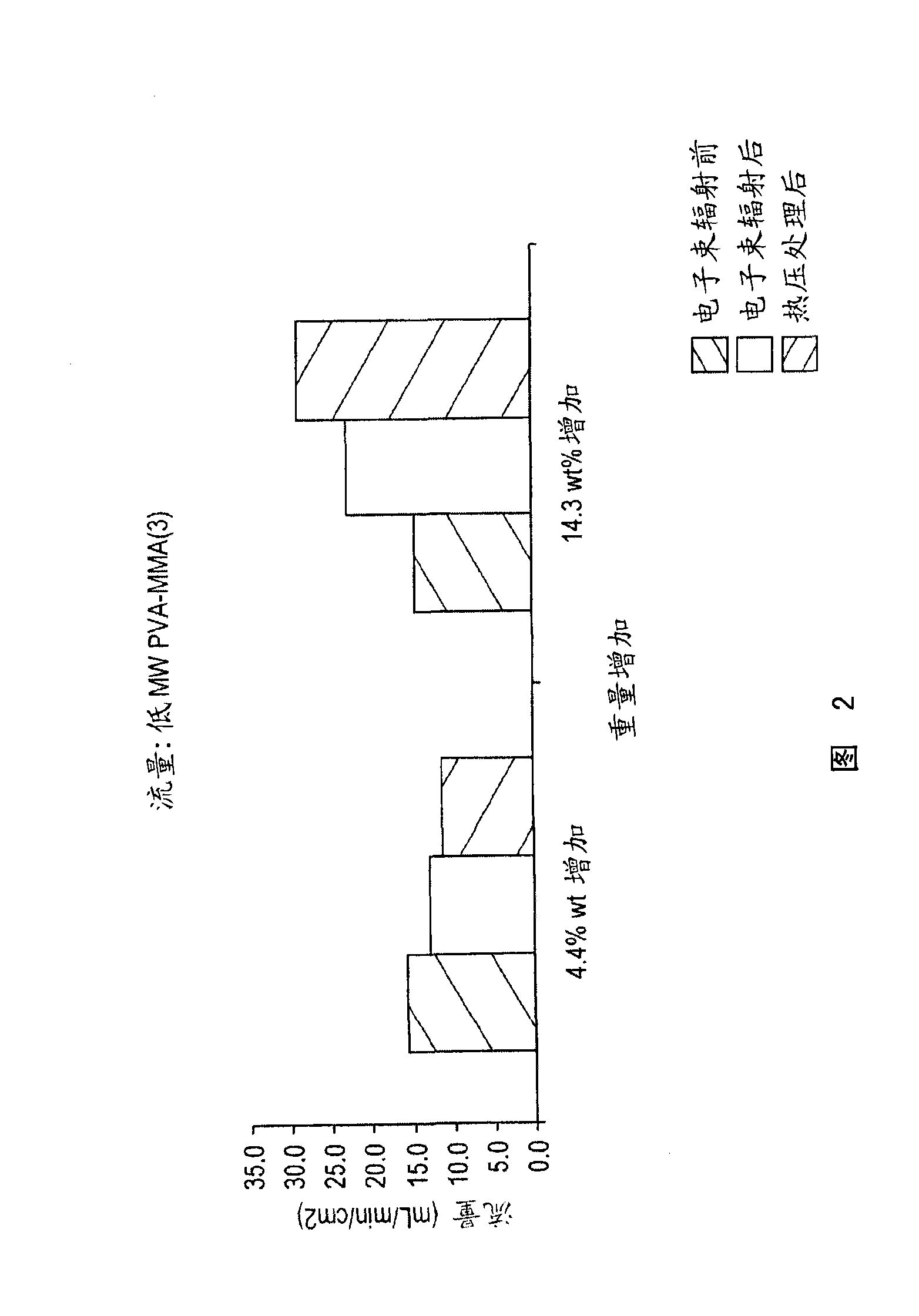

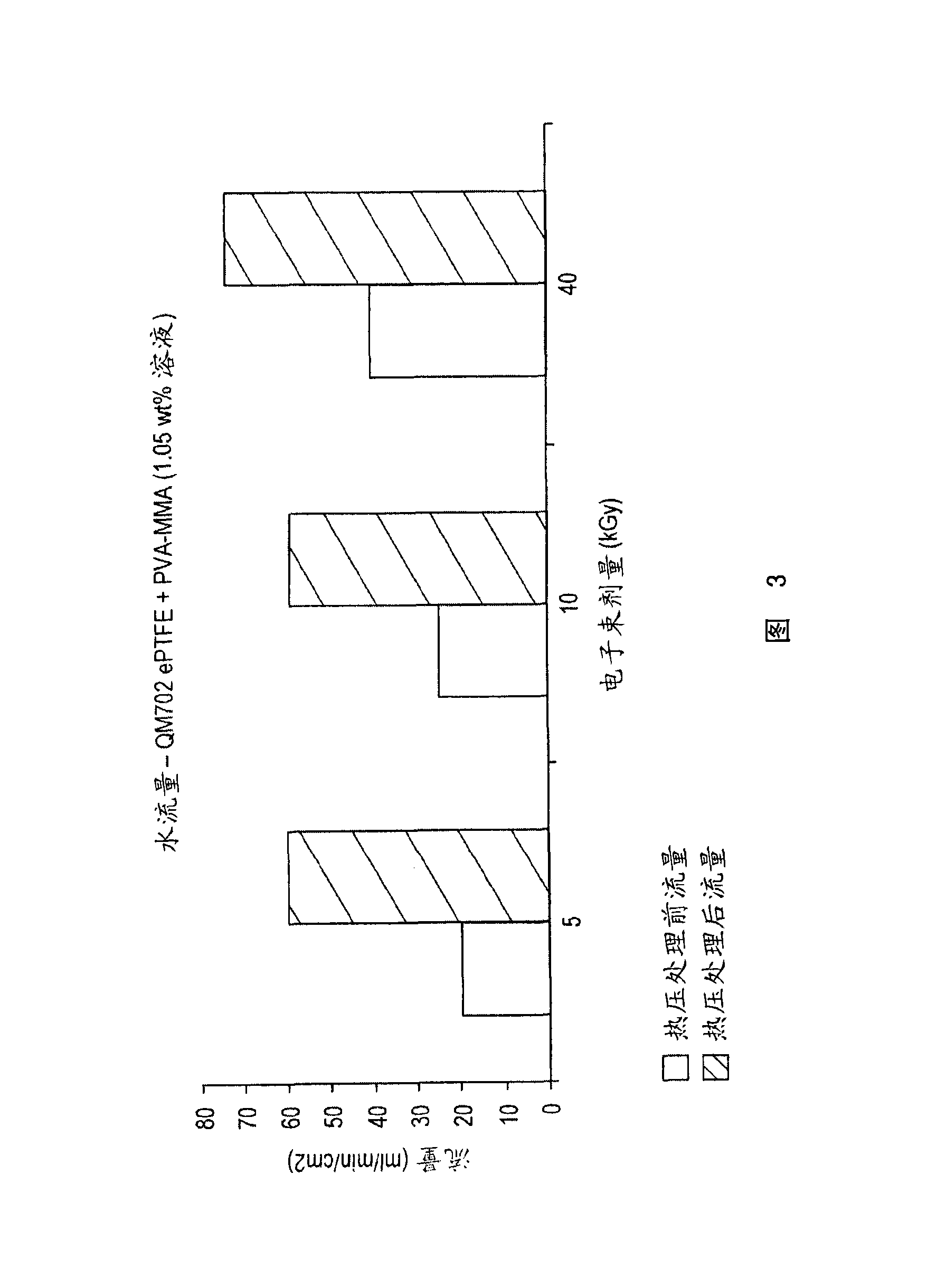

Processes for forming permanent hydrophilic porous coatings onto a substrate, and porous membranes thereof

A membrane includes a base membrane; and an electron beam functionalized coating, the coating comprising a polyvinyl alcohol, a polyvinyl alcohol-polyvinyl amine copolymer, a polyvinyl amine, and derivatives thereof functionalized with an electron beam reactive group adapted to form a radical under high energy irradiation. Also disclosed are processes for forming the membrane.

Owner:GENERAL ELECTRIC CO

Processes for forming permanent hydrophilic porous coatings onto a substrate, and porous membranes thereof

The invention relates to a process for forming permanent hydrophilic porous coatings onto a substrate, and porous membranes thereof. A membrane includes a base membrane; and an electron beam functionalized coating, the coating comprising a polyvinyl alcohol, a polyvinyl alcohol-polyvinyl amine copolymer, a polyvinyl amine, and derivatives thereof functionalized with an electron beam reactive group adapted to form a radical under high energy irradiation. Also disclosed are processes for forming the membrane.

Owner:PARKER HANNIFIN CORP

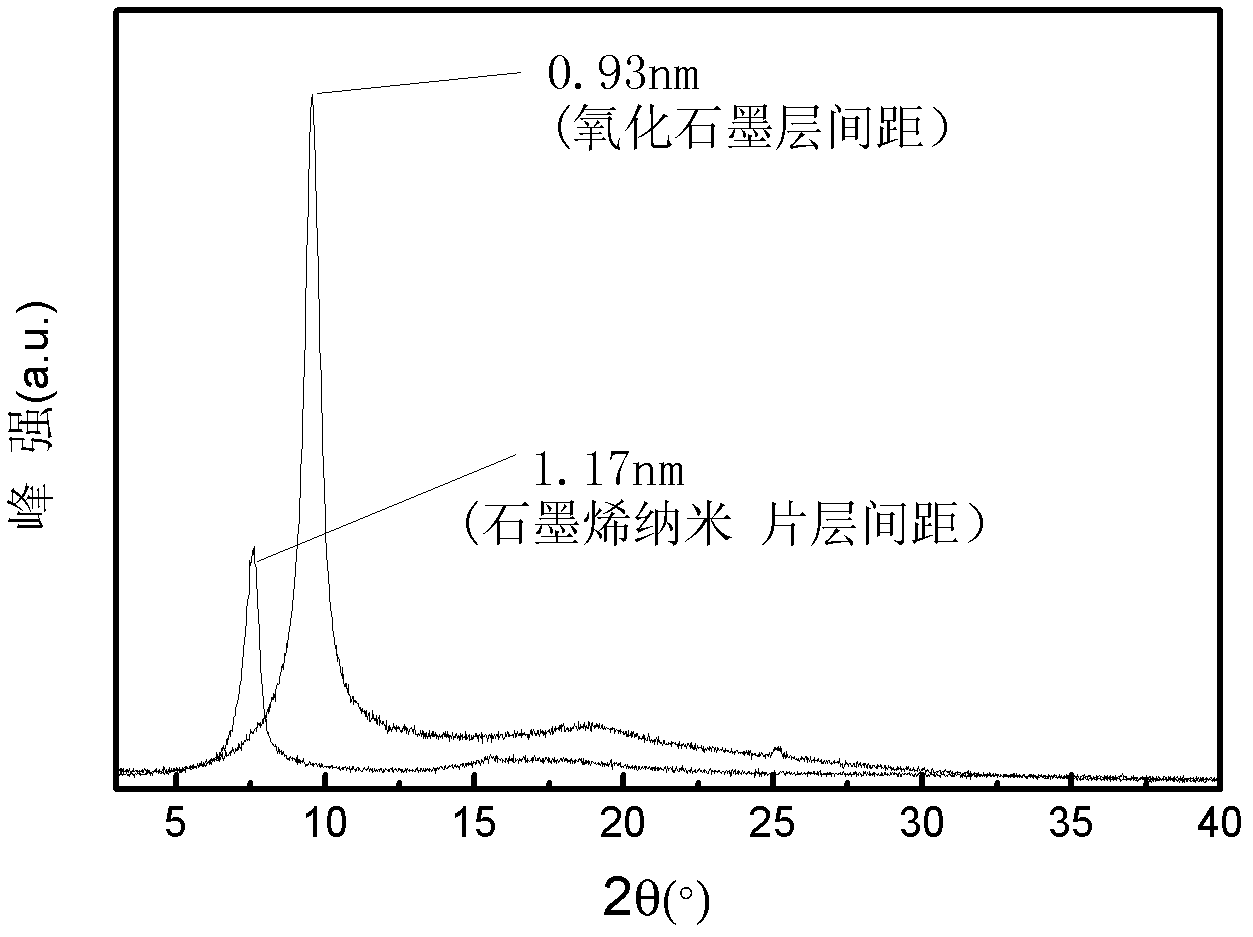

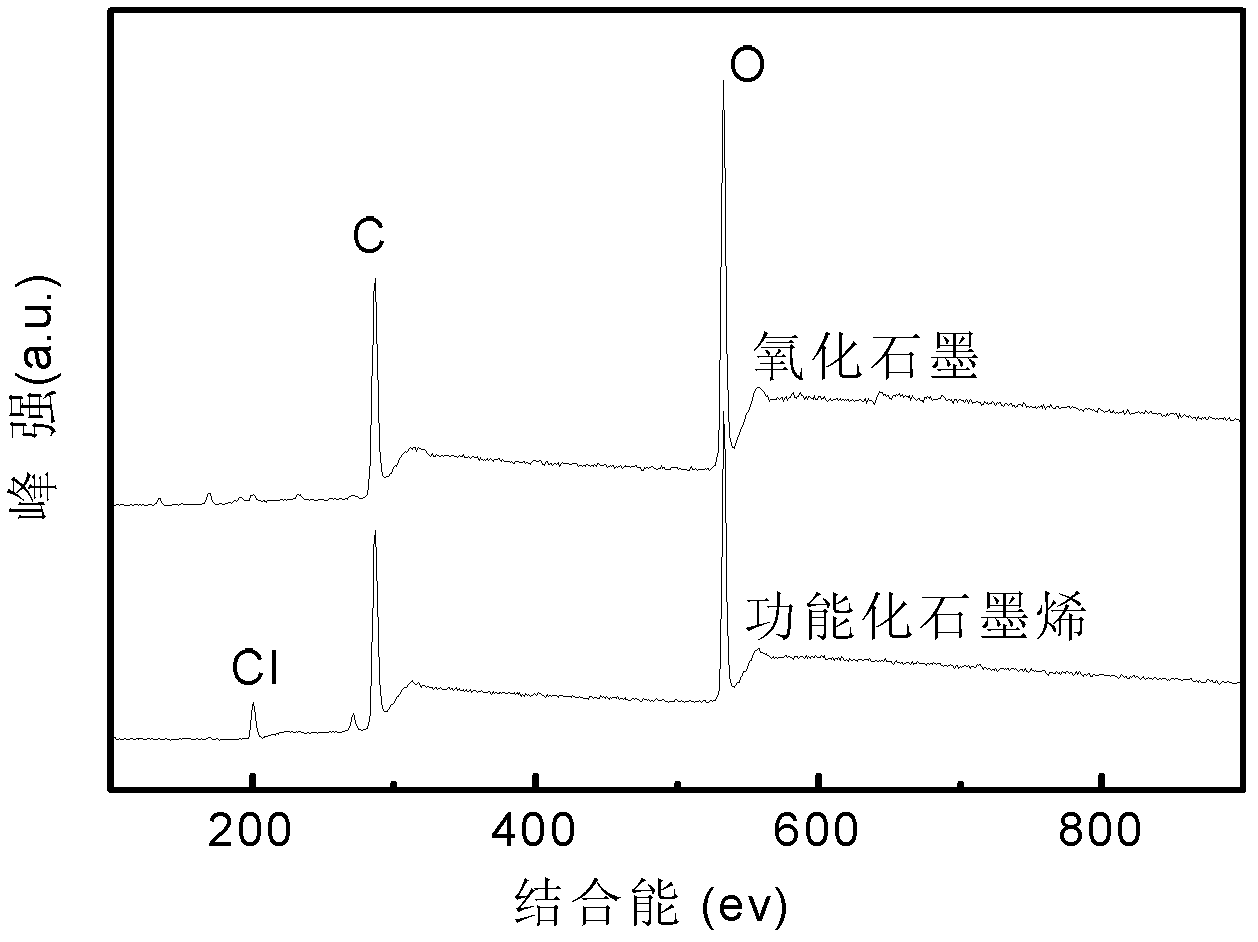

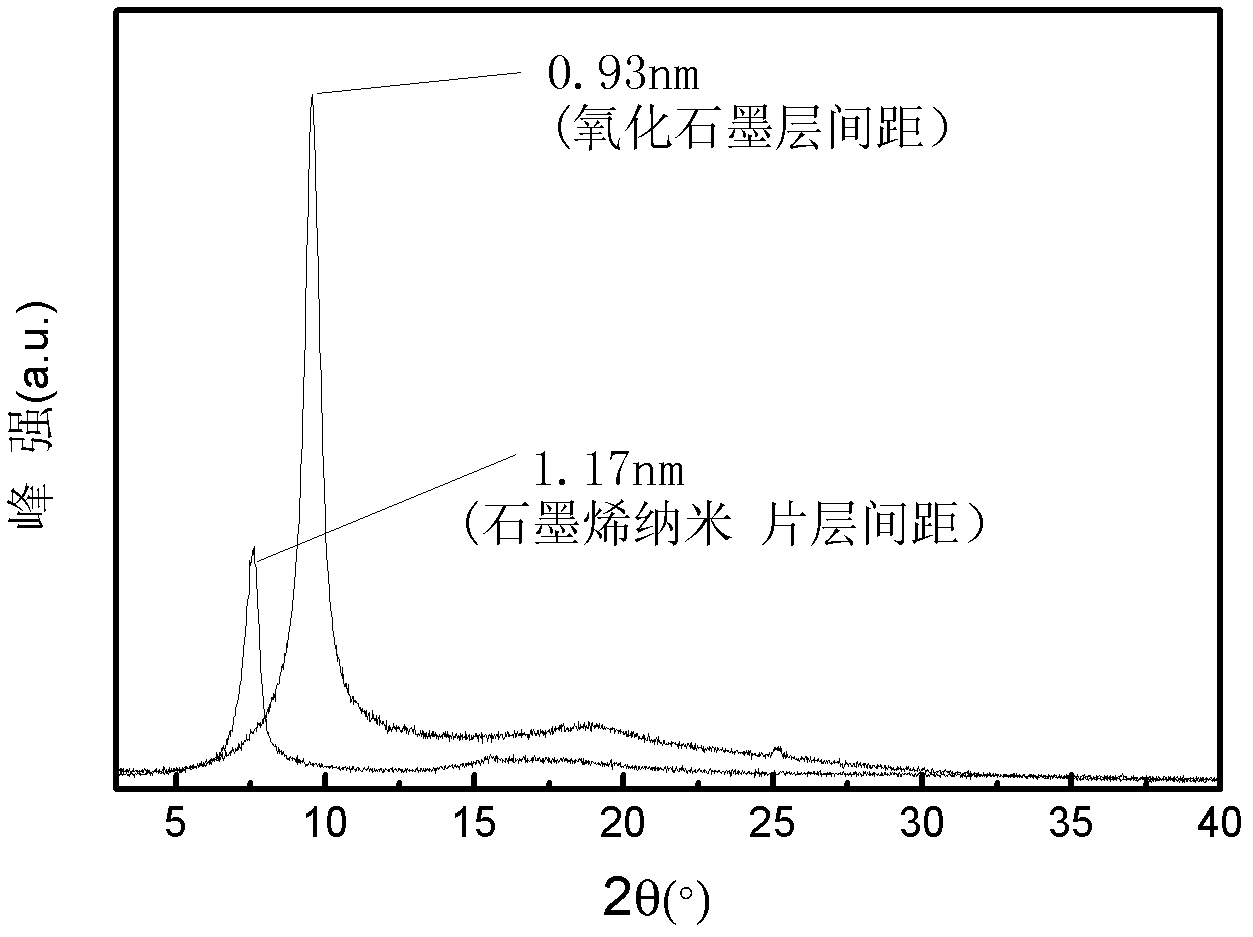

Method for preparing functionalized graphene based on high-energy irradiation one-step method

The invention discloses a method for preparing functionalized graphene based on a high-energy irradiation one-step method. The method comprises the following steps of: mixing graphite oxide and polar small molecular organic solvent, and performing ultrasonic dispersion treatment on the mixed solution for 0.5 to 2 hours, wherein the polar small molecular organic solvent is one or more of epoxy chloropropane, styrene / acetone solution, acrylic acid and lactic acid; and putting the dispersion in an irradiation source chamber of 60 Co, performing gamma ray irradiation on the mixed solution under the conditions that the irradiation dose rate is 0.6*10<3> to 6*10<3>Gy / h and the irradiation dose is 1*10<4> to 2*10<6>Gy, so that the surface of the graphite oxide is peeled, and functionalized graphene nano sheets are formed. By using the characteristics of high energy and strong penetrating power of gamma ray particles in the method, the functionalized small molecular organic substance intercalated into graphite oxide layers and the graphite oxide layers undergo grafting reaction, so that the distance between the graphite oxide layers is increased, and the graphene nano sheets are formed by peeling.

Owner:TIANJIN POLYTECHNIC UNIV

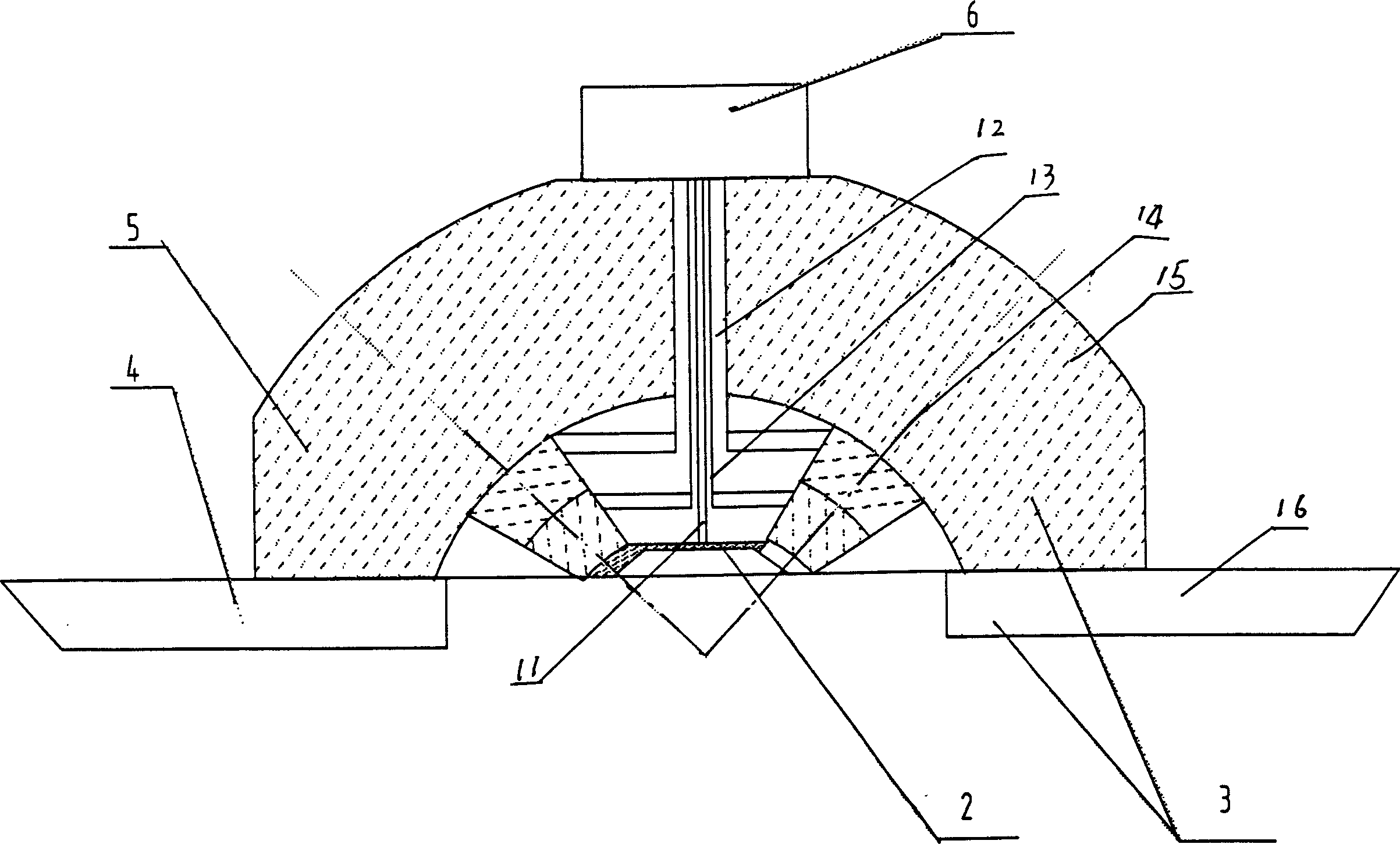

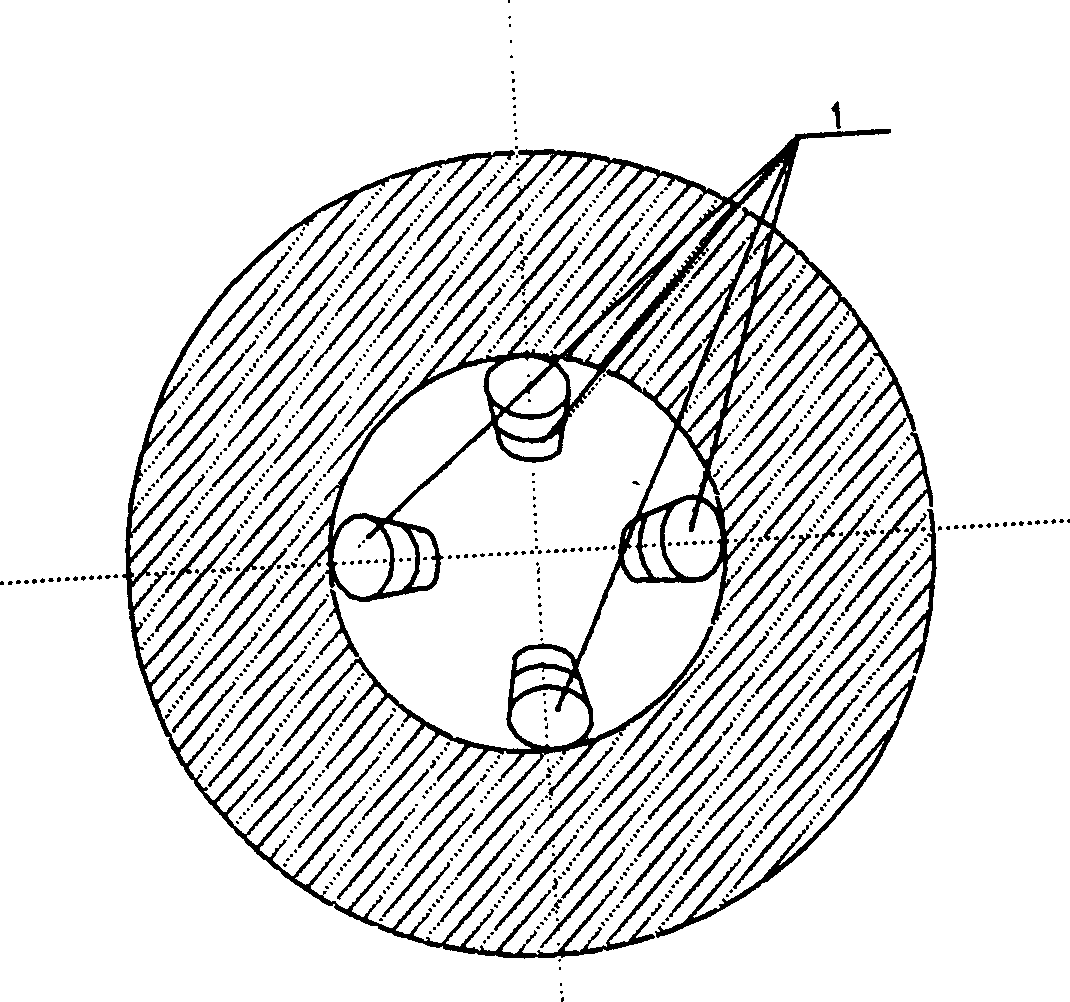

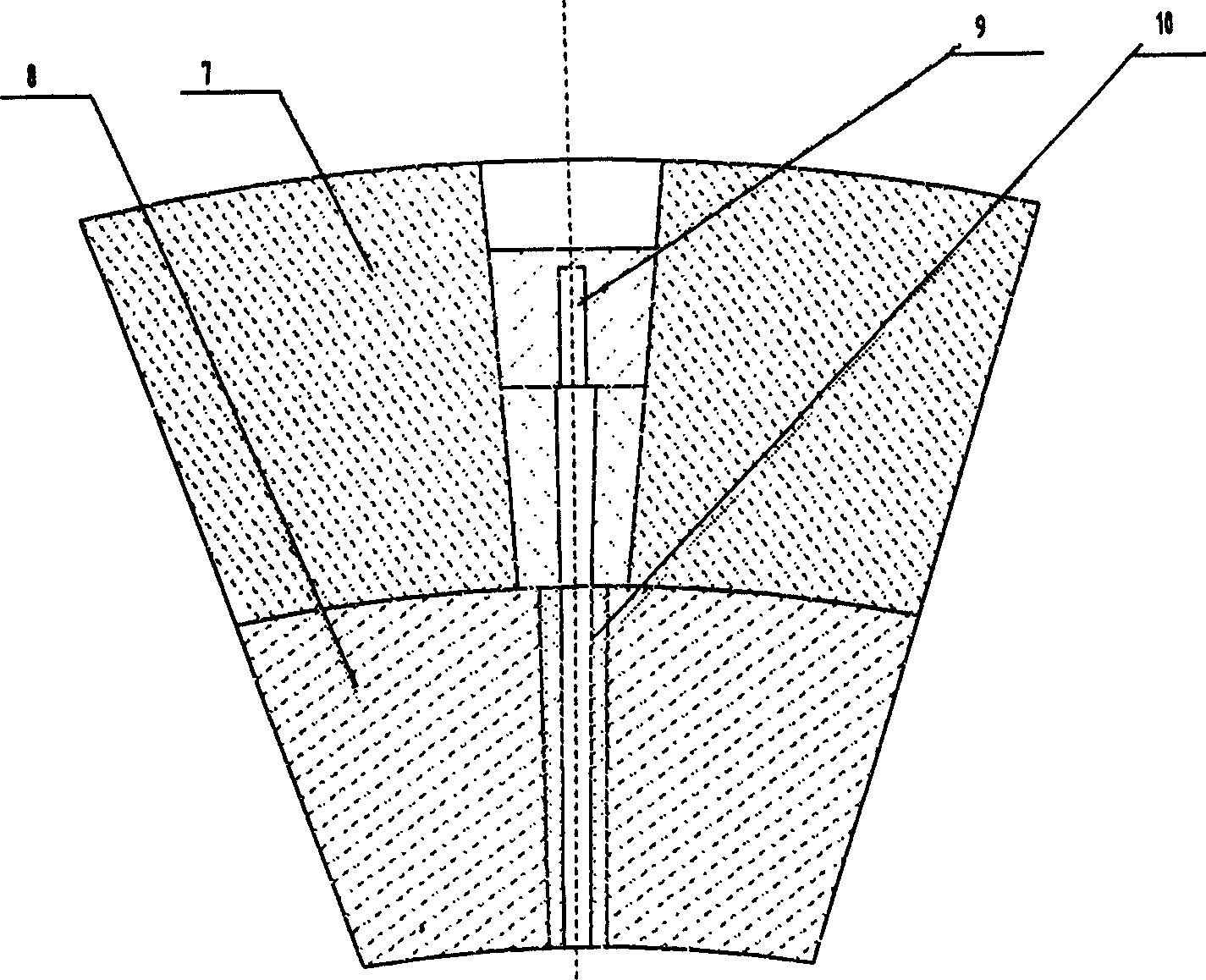

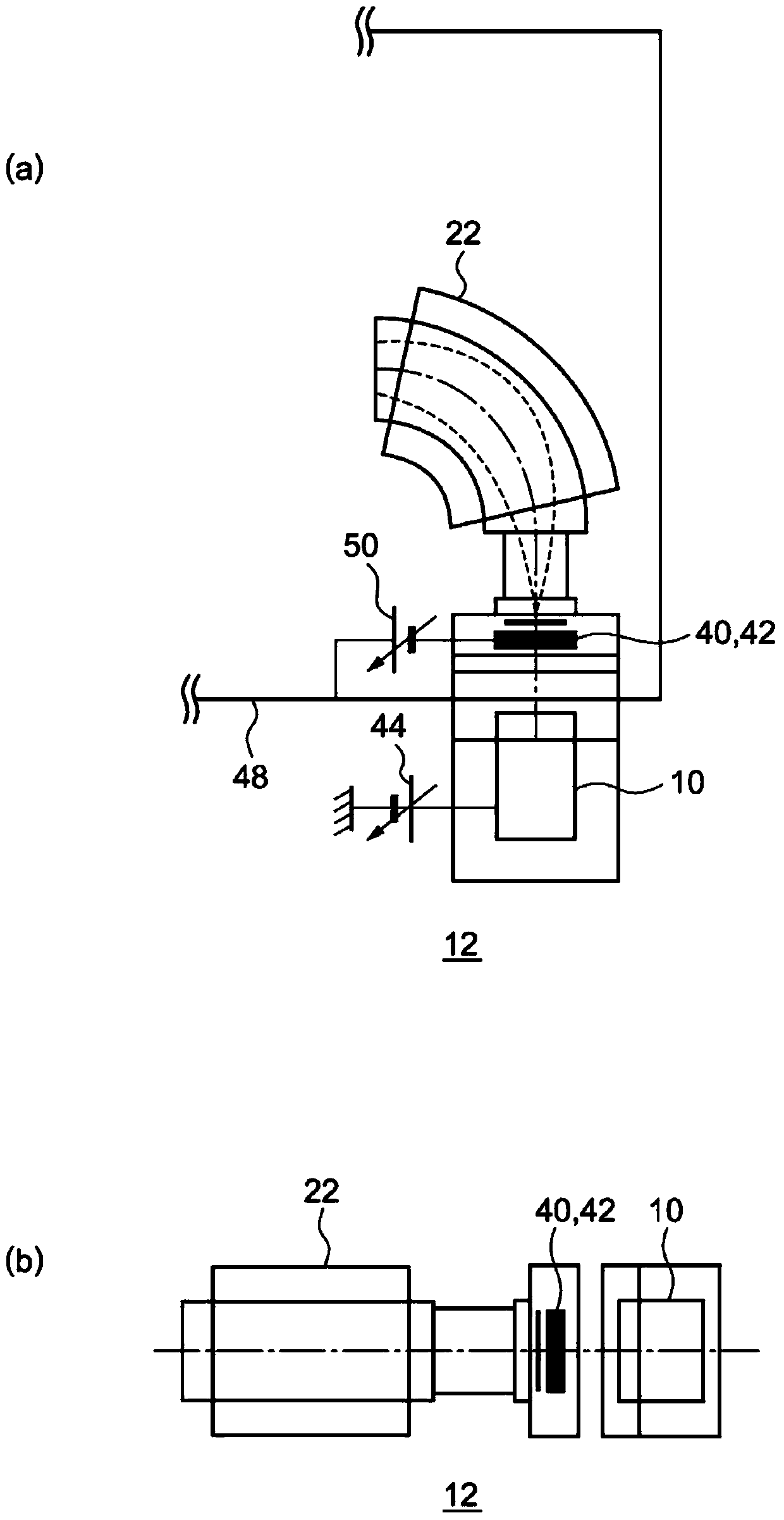

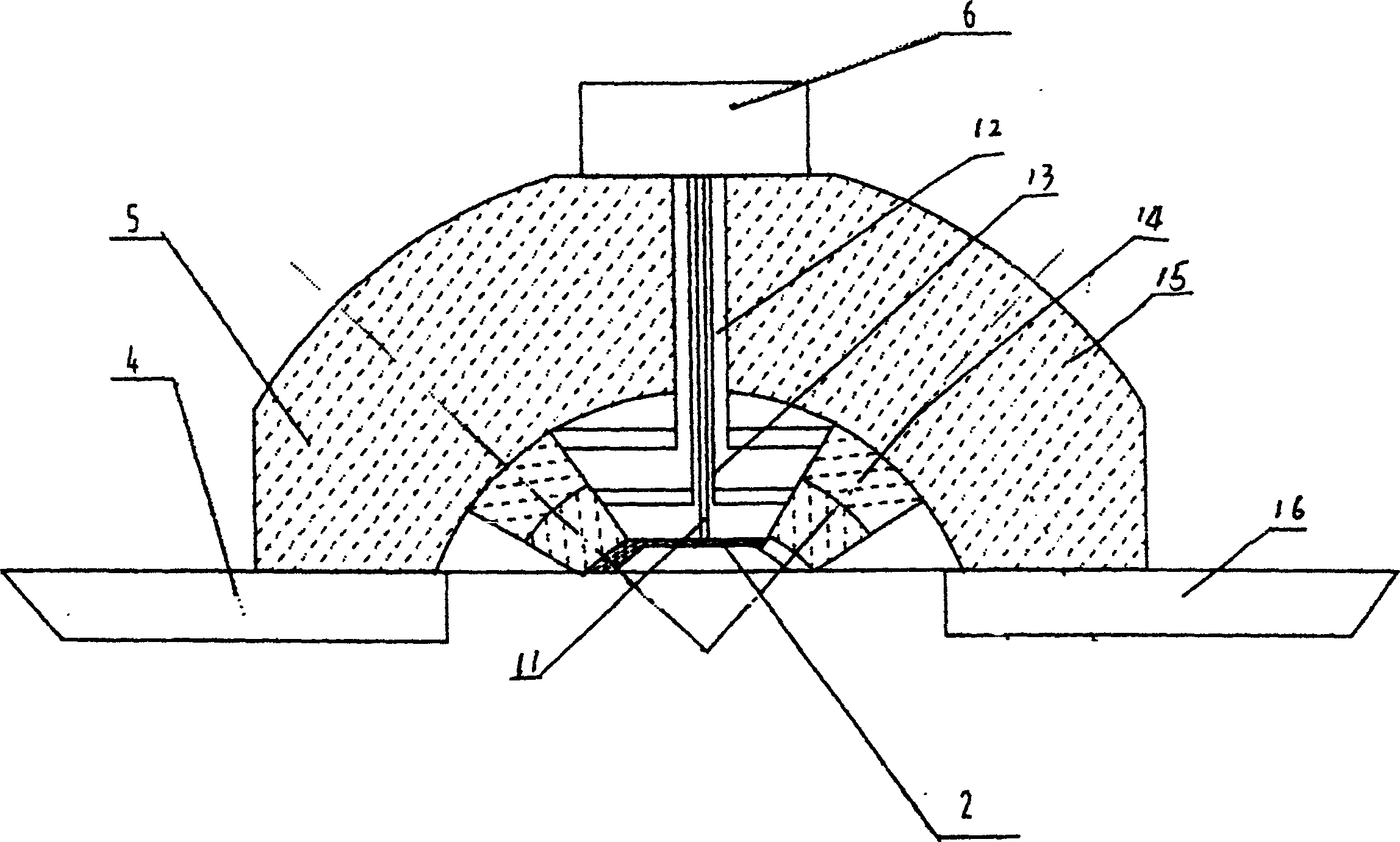

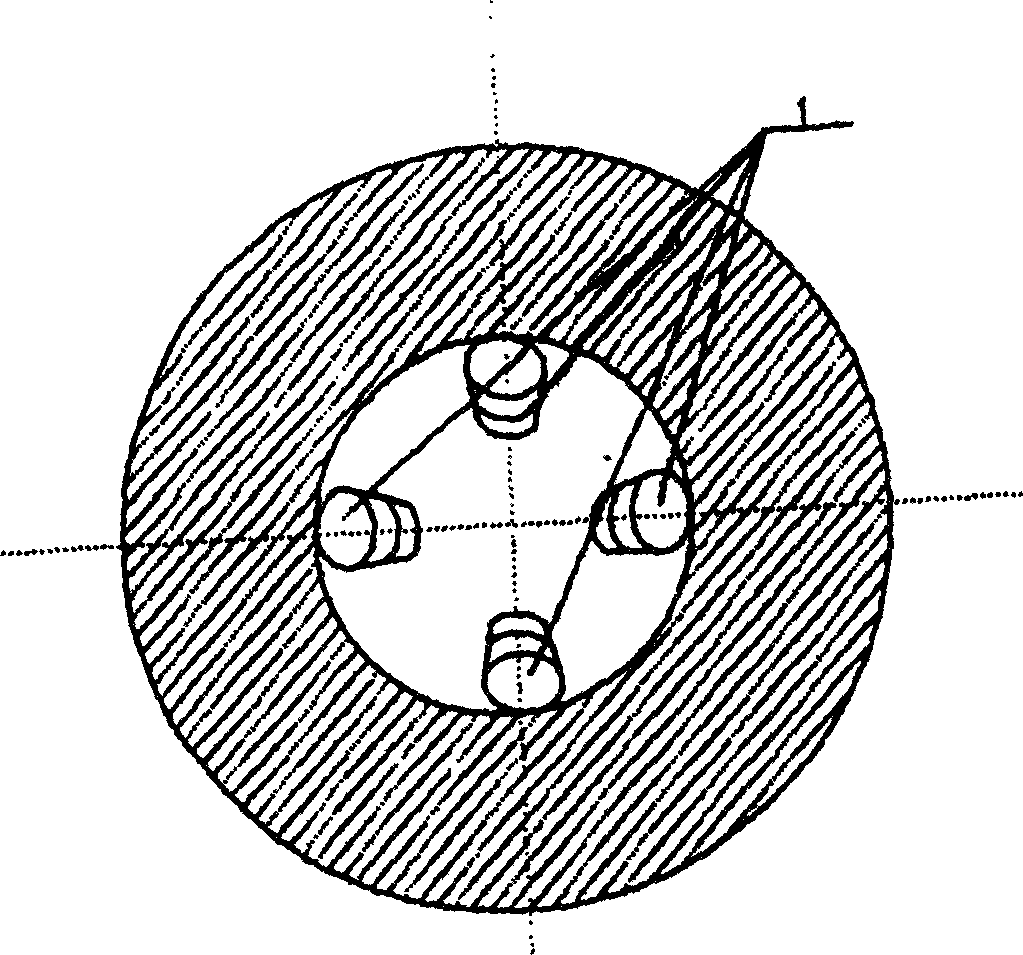

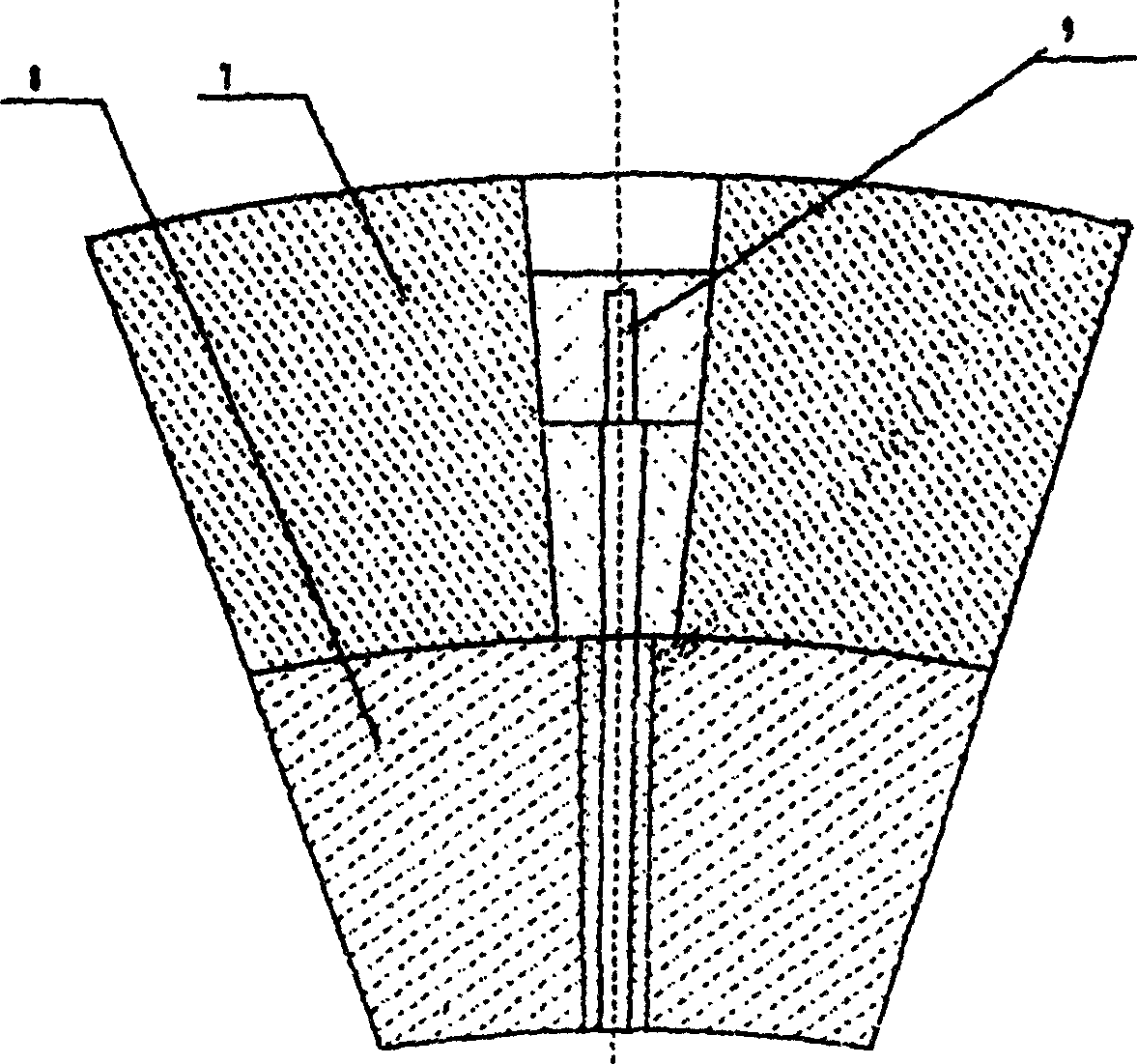

Directional intensity ajustable radiation therapy apparatus

InactiveCN1520899ATo achieve the function of stereotaxic therapyTo achieve the effect of intensity modulationSurgical instrument detailsX-ray/gamma-ray/particle-irradiation therapyDiseaseGamma ray

The directional strengthen regulating radiotherapeutic apparatus includes shielding and protecting assembly, focusing units, strengthen regulating board and driving mechanism. The advantage of the present invention is that the independently rotated and focused units may be laid in different angles to focus the dispersive rays, such as gamma rays, onto the disease focus, so that the disease focus obtains high energy irradiation while the health tissue obtains very lower irradiation, reaching stereo directional treatment. By means of the control of the switches and speeds of the focusing units and the strengthen regulating board, the spatial distribution of the dosage absorbed by the disease focus is regulated and the important tissue of the patient may be protected by means of the independent switching function.

Owner:WUHAN KANGQIAO MEDICAL NEW TECH CO LTD

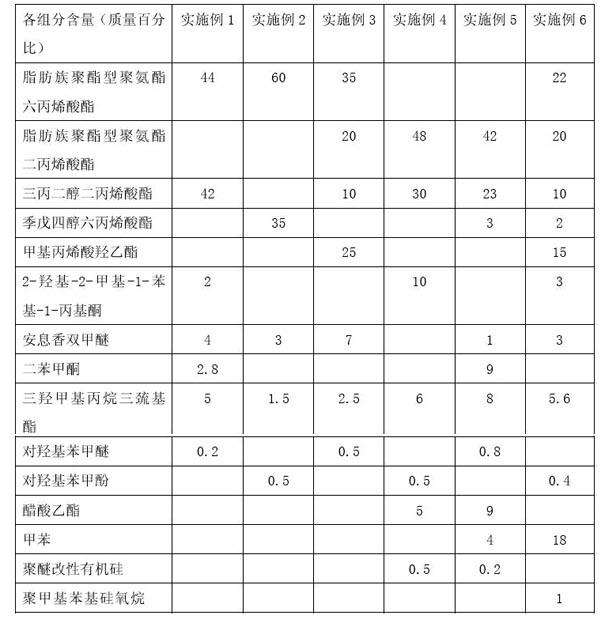

Ultraviolet curing painting capable of being cured at low energy

The invention discloses an ultraviolet curing painting capable of being cured at low energy. The ultraviolet curing painting comprises the following components in percentage by mass: 40 to 60 percent of photosensitive resin, 25 to 45 percent of crosslinking diluent, 2 to 12 percent of photoinitiator, 1 to 8 percent of trimethylolpropane tri-sulfenyl ester, and 0.1 to 0.8 percent of ultraviolet storage stabilizing agent. The painting can be cured under natural light irradiation by adding the trimethylolpropane tri-sulfenyl ester and the ultraviolet storage stabilizing agent without higher energy irradiation.

Owner:上海硕律管理咨询有限公司

Processes for forming a permanent hydrophilic surface on a porous membrane

The invention discloses a permanent hydrophilic porous coating on a substrate, and porous membrane thereof. A membrane includes a base membrane; and an electron beam functionalized coating, the coating comprising a polyvinyl alcohol, a polyvinyl alcohol-polyvinyl amine copolymer, a polyvinyl amine, and derivatives thereof functionalized with an electron beam reactive group adapted to form a radical under high energy irradiation. Also disclosed are processes for forming the membrane.

Owner:PARKER HANNIFIN CORP

Crosslinkable polyamide molding compounds and molded parts produced therewith

The invention relates to crosslinkable, thermoplastic polyamide molding compounds, the polyamides being selected among a group comprising amorphous or microcrystalline polyamides, copolyamides thereof and the blends thereof, and blends of such polyamides with semicrystalline polyamides. One inventive polyamide molding compound is characterized in that the same contains a crosslinking additive which causes the production of crosslinked molded parts formed from said polyamide molding compound under the effect of high-energy irradiation, said molded parts having a glass transition temperature of>140 DEG C and a minimum dimensional stability of 90 percent at temperatures of > 180 DEG C. The polyamides have a substantially linear structure while the monomers thereof contain no olefinic C=C double bonds. Also disclosed are corresponding crosslinked molded polyamide parts produced from a polyamide molding compound as well as the use of the polyamide molding compound for producing the crosslinked molded polyamide parts.

Owner:EMS CHEM AG

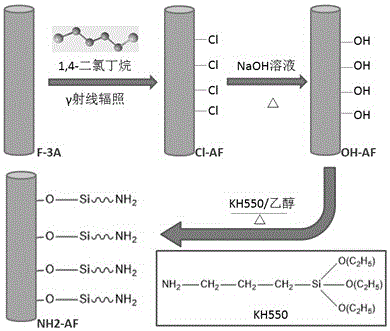

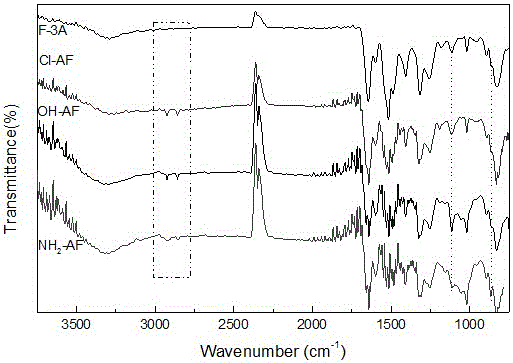

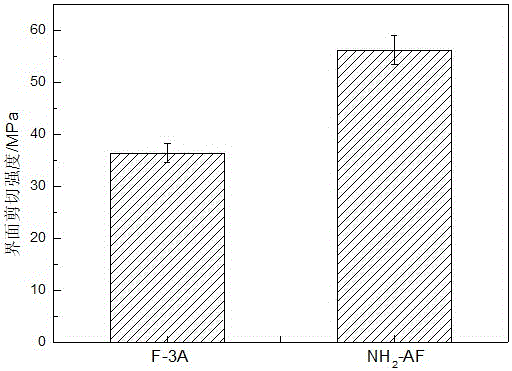

Method for modifying aramid fibers by silane coupling agent

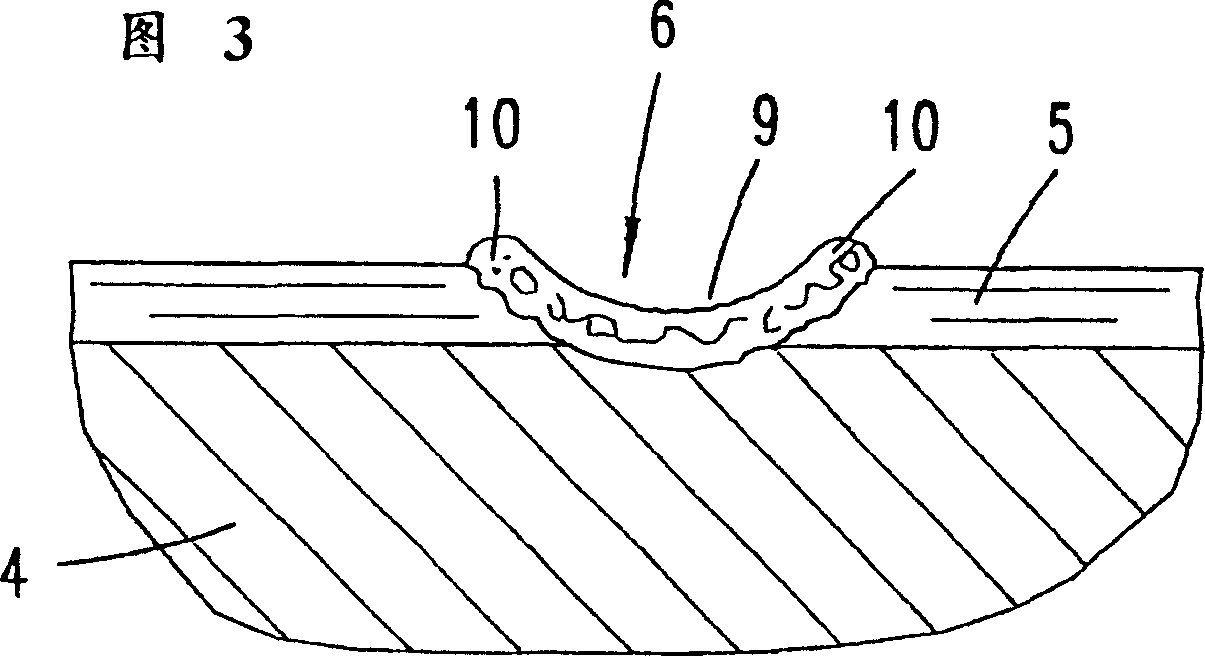

InactiveCN106120330AImproved "skin-core" structureImprove surface activityPhysical treatmentFibre typesSurface cleaningGraft reaction

A method for modifying aramid fiber with a silane coupling agent, the method comprises four steps of cleaning and drying the fiber surface, chlorination reaction on the fiber surface, hydroxylation reaction on the fiber surface and grafting silane coupling agent reaction on the fiber surface. The invention adopts gamma ray high-energy irradiation to treat aramid fibers, and uses 1,4-dichlorobutane as a grafting agent to irradiate aramid fibers and 1,4-dichlorobutane to initiate grafting on the fiber surface reaction, introduce -Cl functional group, and then use NaOH solution to carry out hydroxylation treatment, convert -Cl to -OH, introduce -OH on the surface of the fiber, and finally react the hydroxylated aramid fiber with the aminosilane coupling agent KH550 to activate Fiber surface, improve fiber interface performance. The process of the invention is simple and efficient, the fibers can be processed in batches, the reaction solvent can be reused many times, the invention is green and environmentally friendly, and is suitable for large-scale industrial production.

Owner:HARBIN INST OF TECH

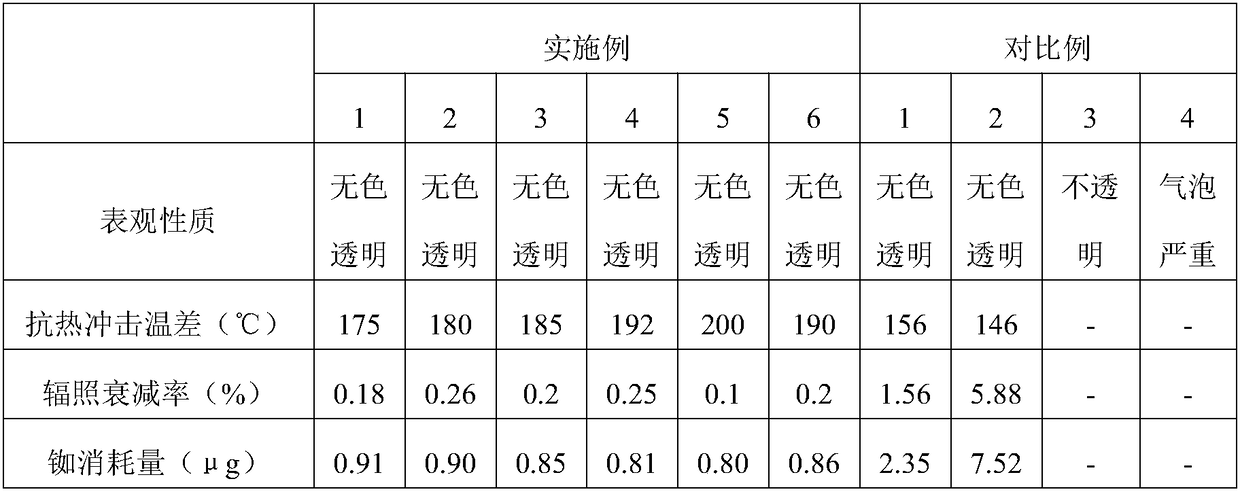

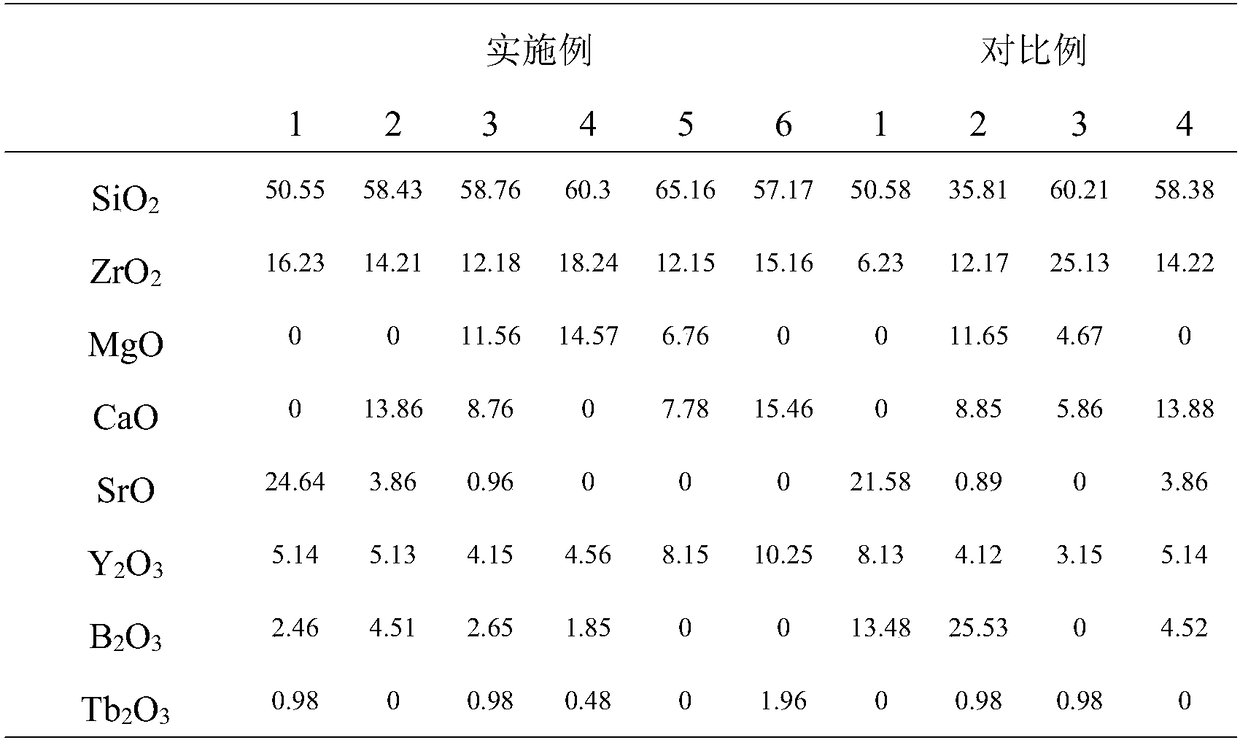

High-ZrO2-content silicate glass and preparing method thereof

ActiveCN108558201AGood chemical stabilityLower melting temperatureGlass furnace apparatusRubidiumSilicate glass

The invention belongs to the technical field of special glass preparing, and particularly relates to high-ZrO2-content silicate glass and a preparing method thereof. The glass is prepared from, by weight, 50-65% of SiO2, 12-18% of ZrO2, 15-25% of RO, 4-10% of Y2O3, 0-5% of B2O3 and 0-2% of Tb2O3, wherein RO is one or more of MgO, CaO and SrO. The preparing method includes the steps of raw materialpreprocessing, high-temperature founding, ultrasonic vibration bubble removing, forced stirring, material leakage forming and the like, and finally the silicate glass free of bubbles, stones and stripes is obtained. The obtained glass has good heat impact resistance, high-energy irradiation resistance, chemical stability and the like, especially excellent rubidium vapor resistance, and completelymeets the application requirements of rubidium vapor resistance glass blister packs, sodium vapor resistance modulator tubes and other special devices.

Owner:CHINA BUILDING MATERIALS ACAD

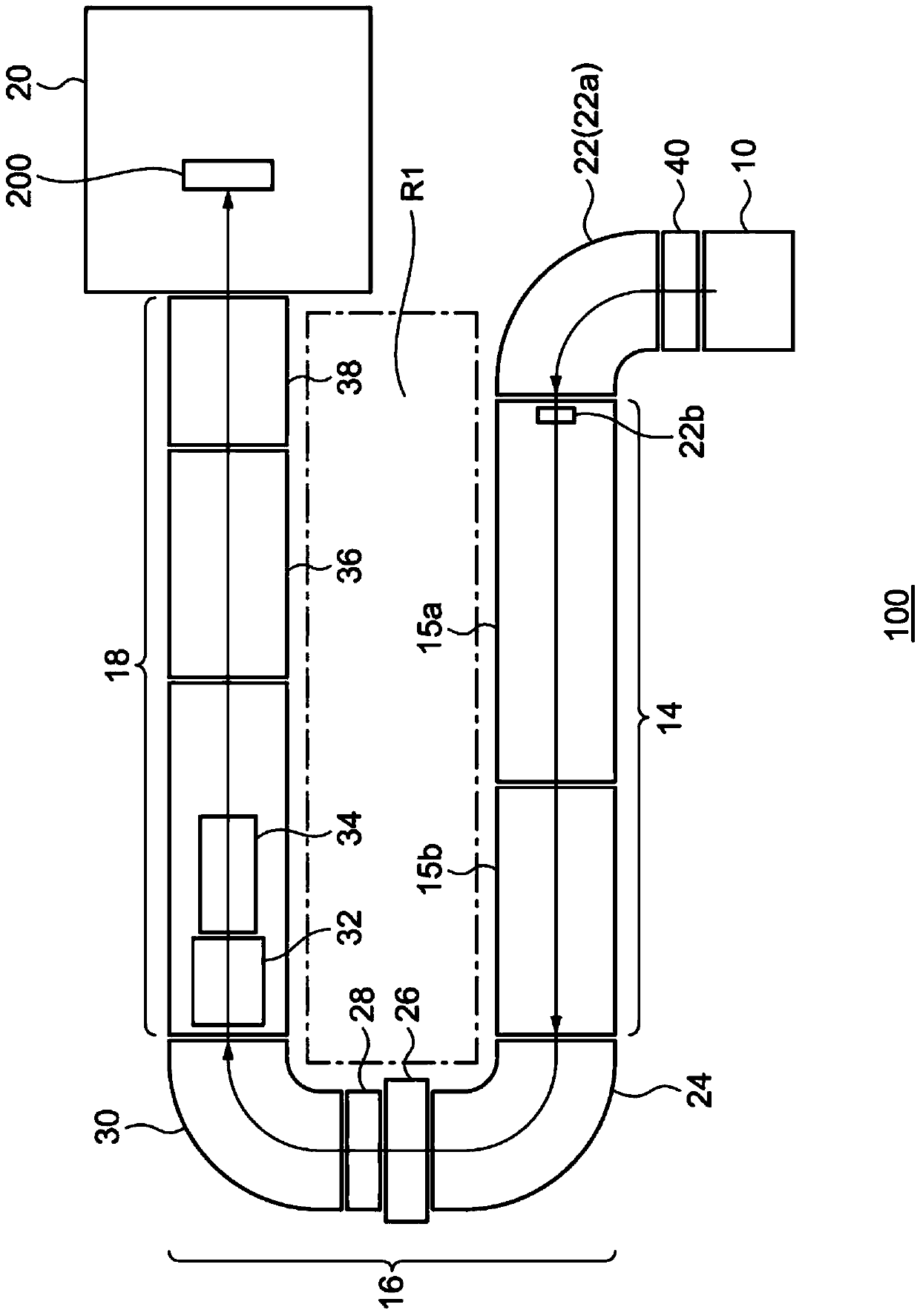

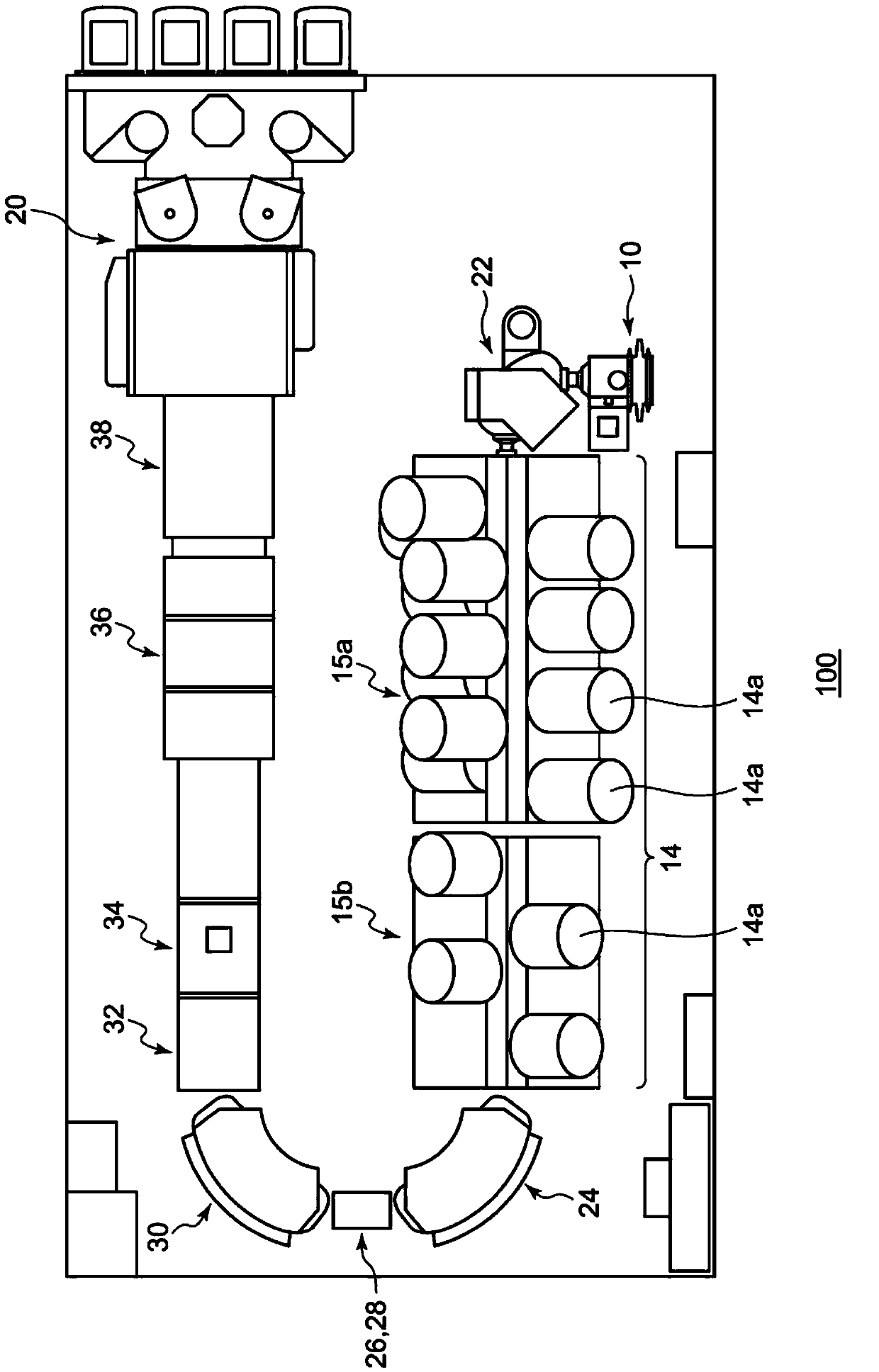

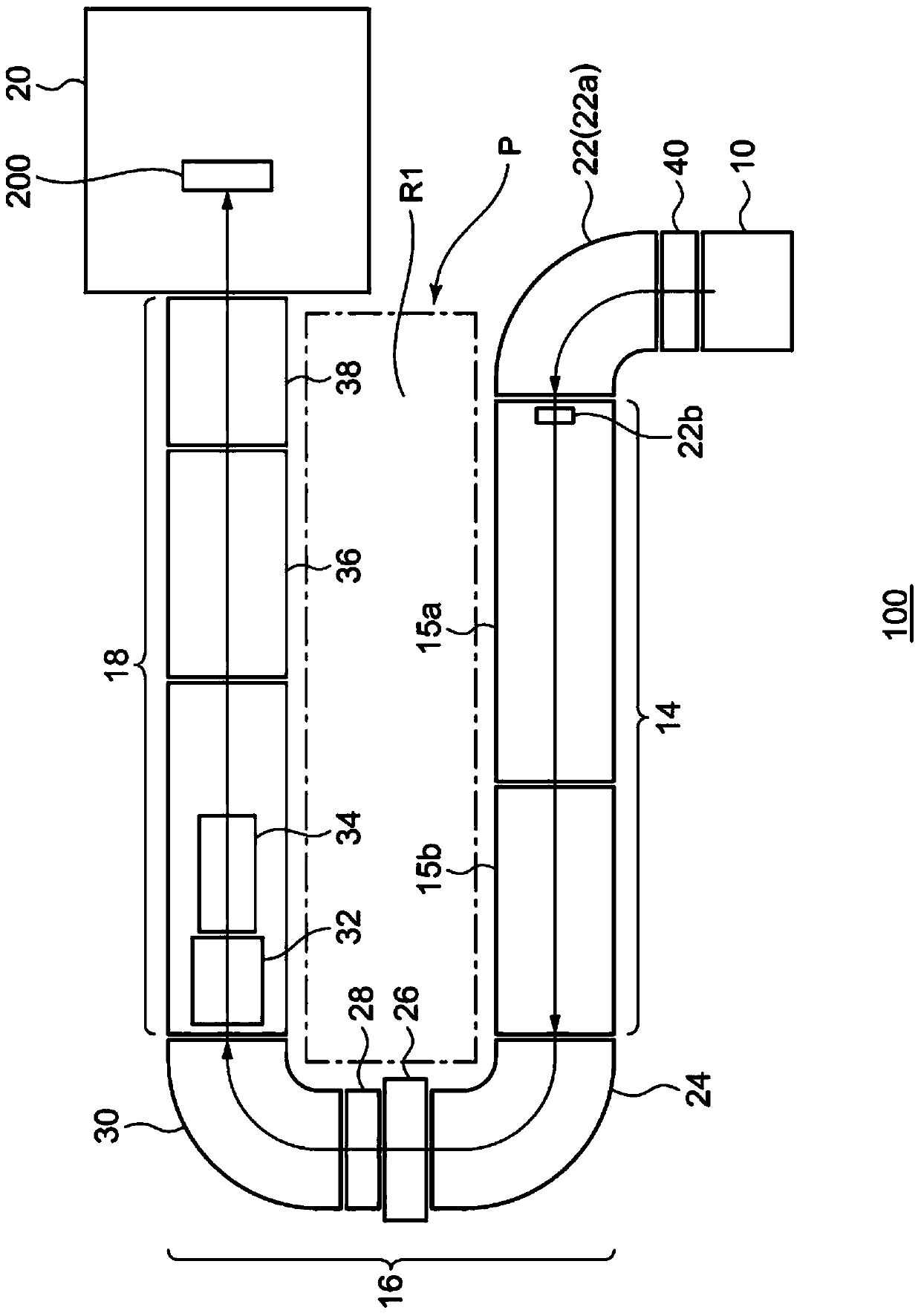

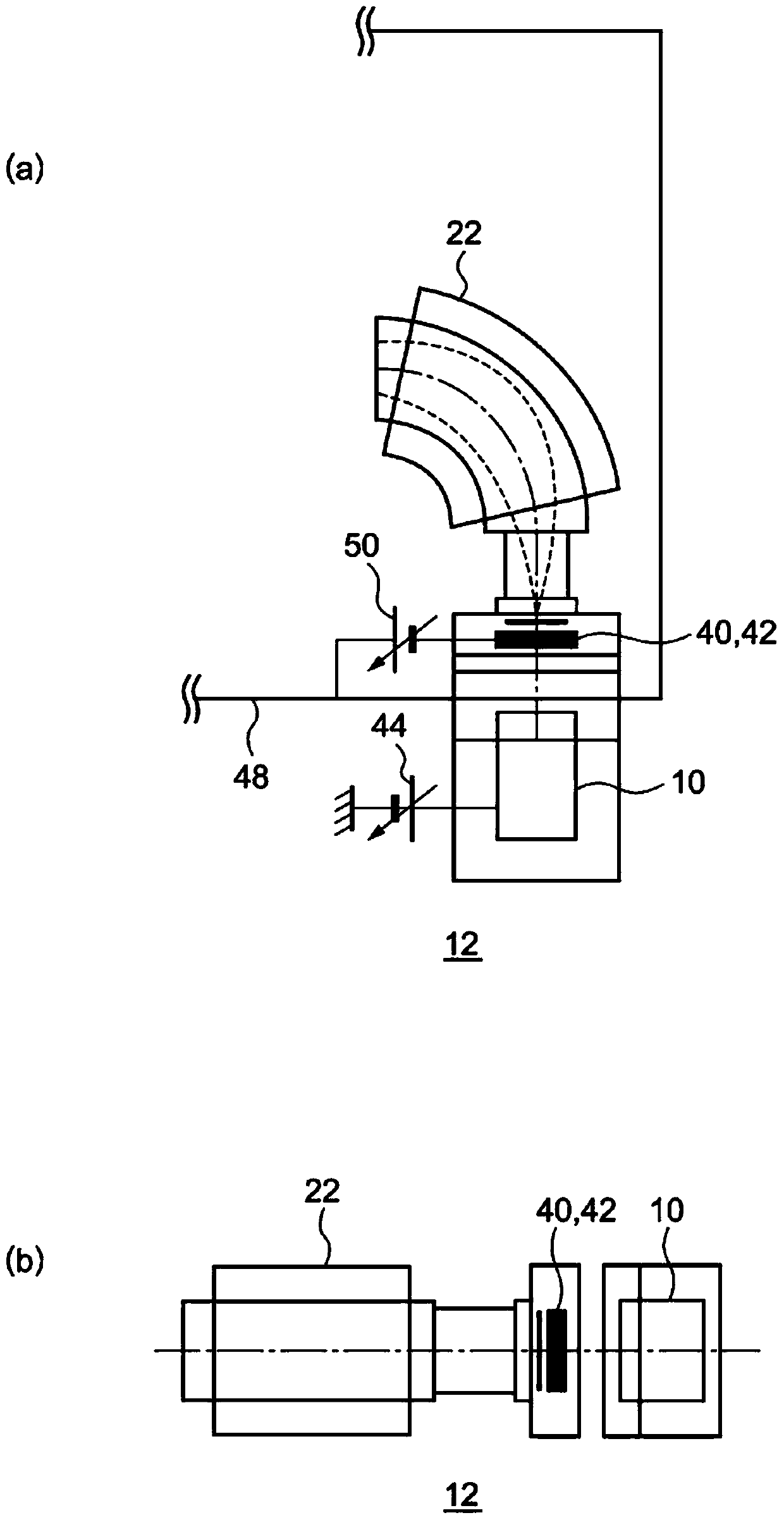

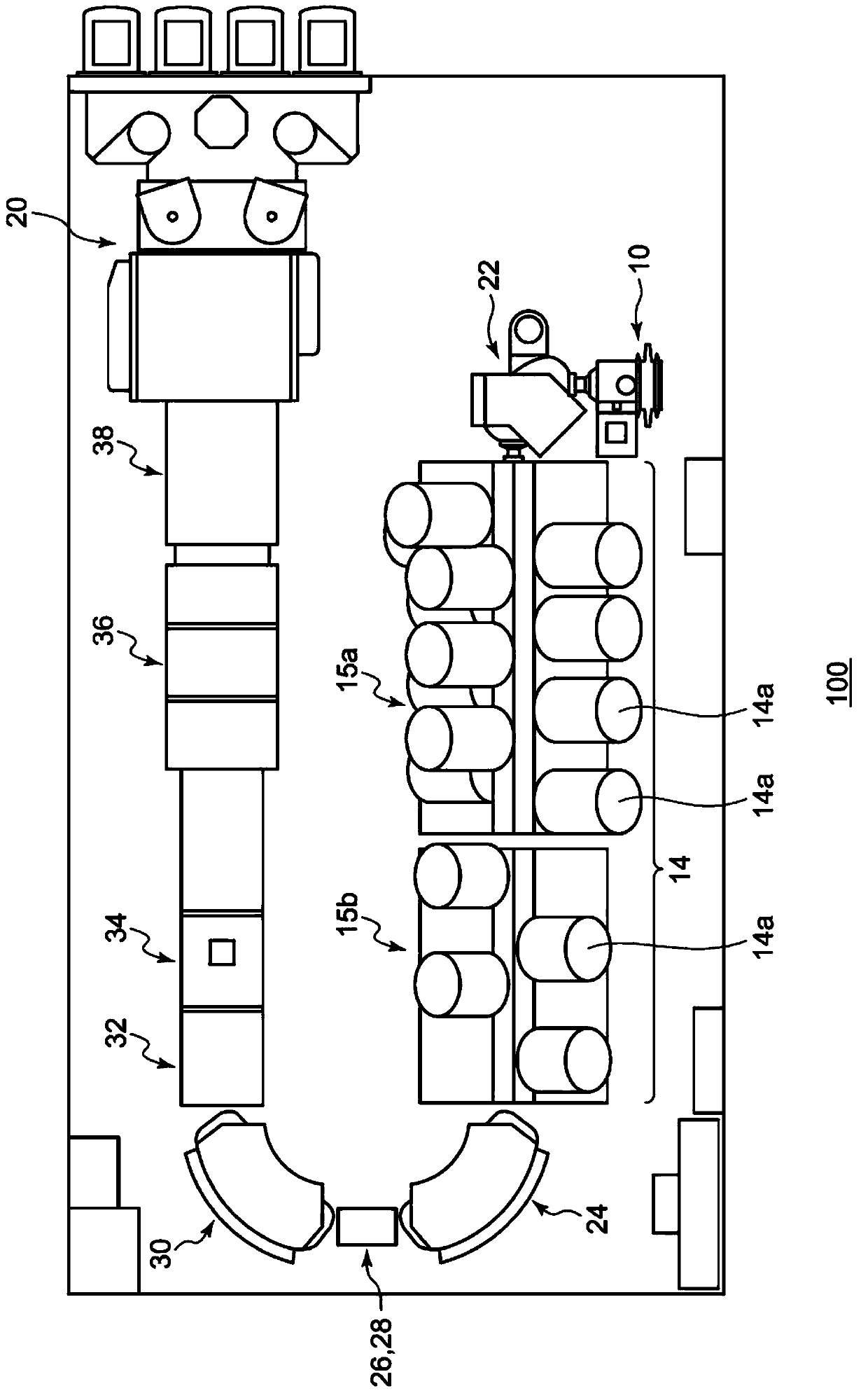

High-energy ion injection device

ActiveCN104183446AAvoid divergenceGuaranteed Energy AccuracyElectric discharge tubesSemiconductor/solid-state device manufacturingHigh energyIon beam

The present invention provides a high-energy ion injection device, which carries out scanning, parallelization, and filtering on high-energy ion beams through an electric field. The high-energy ion injection device (100) comprises: a high energy multi-segment straight line accelerating unit (14), which accelerates the ion beam and thereby generating the high-energy ion beam; a deflection unit (16), which carries out direction conversion on the high-energy ion beam toward a semiconductor wafer; irradiation beam transmission line unit (18), which transmits the deflected high-energy ion beam to the wafer. The irradiation beam transmission line unit (18) comprises an irradiation beam reshaper (32), a high-energy irradiation beam scanner (34), and a high-energy electric field irradiation beam parallelization device (36), and an electric field final energy filter (38).

Owner:SENCORP

High-energy ion injection device

ActiveCN104183449AGuaranteed Energy AccuracySuppress beam divergenceElectric discharge tubesSemiconductor/solid-state device manufacturingHigh energyIon beam

The present invention relates to a high efficiency irradiation beam transmission technology of a high-energy ion injection device. The high-energy ion injection device comprises an irradiation beam generation unit, having an ion source and a quality analyzing device; a high-energy multi-segment straight line acceleration unit, which accelerates an ion beam to generate a high-energy ion beam; a deflection unit of a high-energy irradiation beam, which carries out direction conversion on the high-energy ion beam toward the direction of a wafer; and an irradiation beam transmission line unit which transmits the deflected high-energy ion beam to the wafer. The deflection unit is made of a plurality of deflection electric magnets, and at least a transverse convergence member inserted among the plurality of deflection electric magnets.

Owner:SENCORP

Permanent hydrophilic porous coatings and methods of making them

Owner:PARKER HANNIFIN CORP

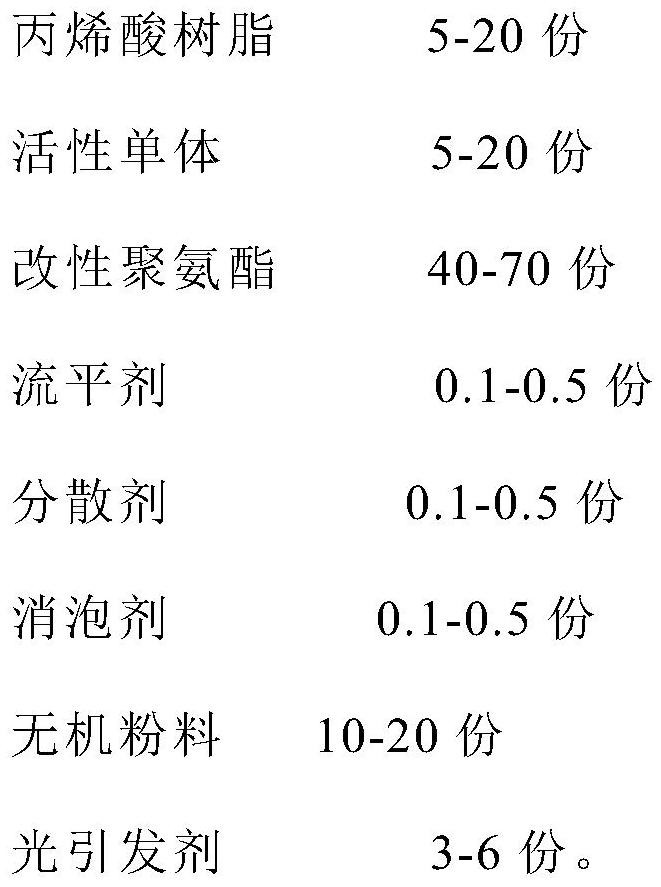

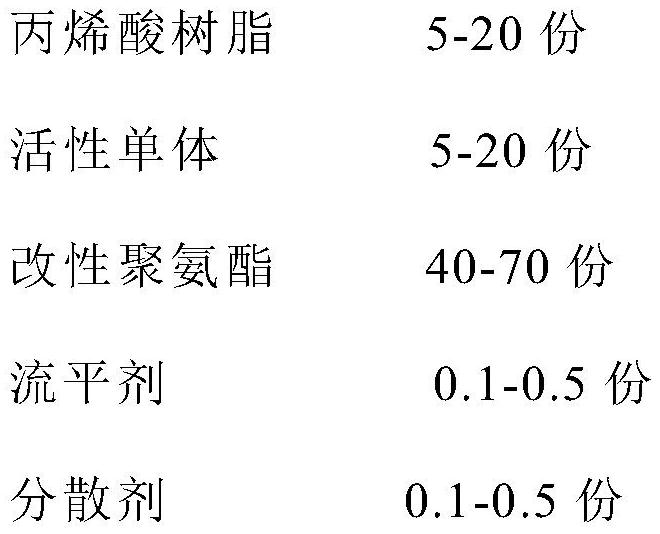

Temporary protection coating for UV illumination demolding and application of temporary protection coating

ActiveCN113667394AStrong contractionTo achieve the fade effectPolyurea/polyurethane coatingsNon-metallic protective coating applicationHigh energyAbsorbed energy

The invention relates to the technical field of coating materials, in particular to a temporary protection coating for UV illumination demolding and application of the temporary protection coating. When holes are directly drilled in the surface of a multi-layer PCB, copper cuttings are easily generated, and the drilling precision is influenced. In order to solve the problems, the invention provides a temporary protection coating material for UV illumination demolding, wherein a free photoinitiator in the coating material absorbs energy under a specific emission wavelength to initiate photocuring of the coating material system, so that a temporary protection coating is formed on the surface of a PCB multilayer circuit board, wherein the specific emission wavelength perfectly avoids the absorption wavelength range of the photoinitiator 2959, after drilling, the PCB multilayer circuit board is placed under a high-pressure mercury lamp for high-energy irradiation, the photoinitiator 2959 fragment of the modified polyurethane structure in the temporary protection coating can absorb a large amount of energy to break, the temporary protection coating is fragmented, and finally, strong shrinkage occurs under the action of high energy, so that automatic stripping from the surface of the PCB multilayer circuit can be realized.

Owner:GUANGDONG HEYGEY LIGHT CURING MATERIALS

Peroxidated heat-vulcanized silicone rubber resistant to irradiation and preparation method thereof

ActiveCN101717581BImprove radiation resistanceImprove mechanical propertiesChemical industryPolymer science

The invention discloses a peroxidated heat-vulcanized silicone rubber resistant to irradiation and a preparation method thereof. The peroxidated heat-vulcanized silicone rubber comprises 100 parts of silicon rubber, 10-60 parts of anti-irradiation agent, 40-70 parts of gaseous white carbon black, 2-7 parts of concentrated crosslinker and 0.5-2.5 parts of vulcanizing agent according to parts by weight, and which is characterized in that the anti-irradiation agent is rare earth oxide. The peroxidated heat-vulcanized silicone rubber resistant to irradiation is prepared from a main material of methyl vinyl silicon rubber by modification; the rubber has strong environmental suitability, and the stretch strength reaches more than 6MPa and the tear strength reaches more than 20KN / m after 500KGy of irradiation; the rubber can be used for producing various rubber products resistant to irradiation such as rubber cushions, sealing parts, buffer elements, distance sleeves, diaphragms, and can be widely applied to the conditions abundant in high-energy irradiation such as aerospace, nuclear industry, electronic communication, chemical industry, medicine and ship; thus, the rubber has very good economic benefit and promotional value.

Owner:SHANDONG UNIV

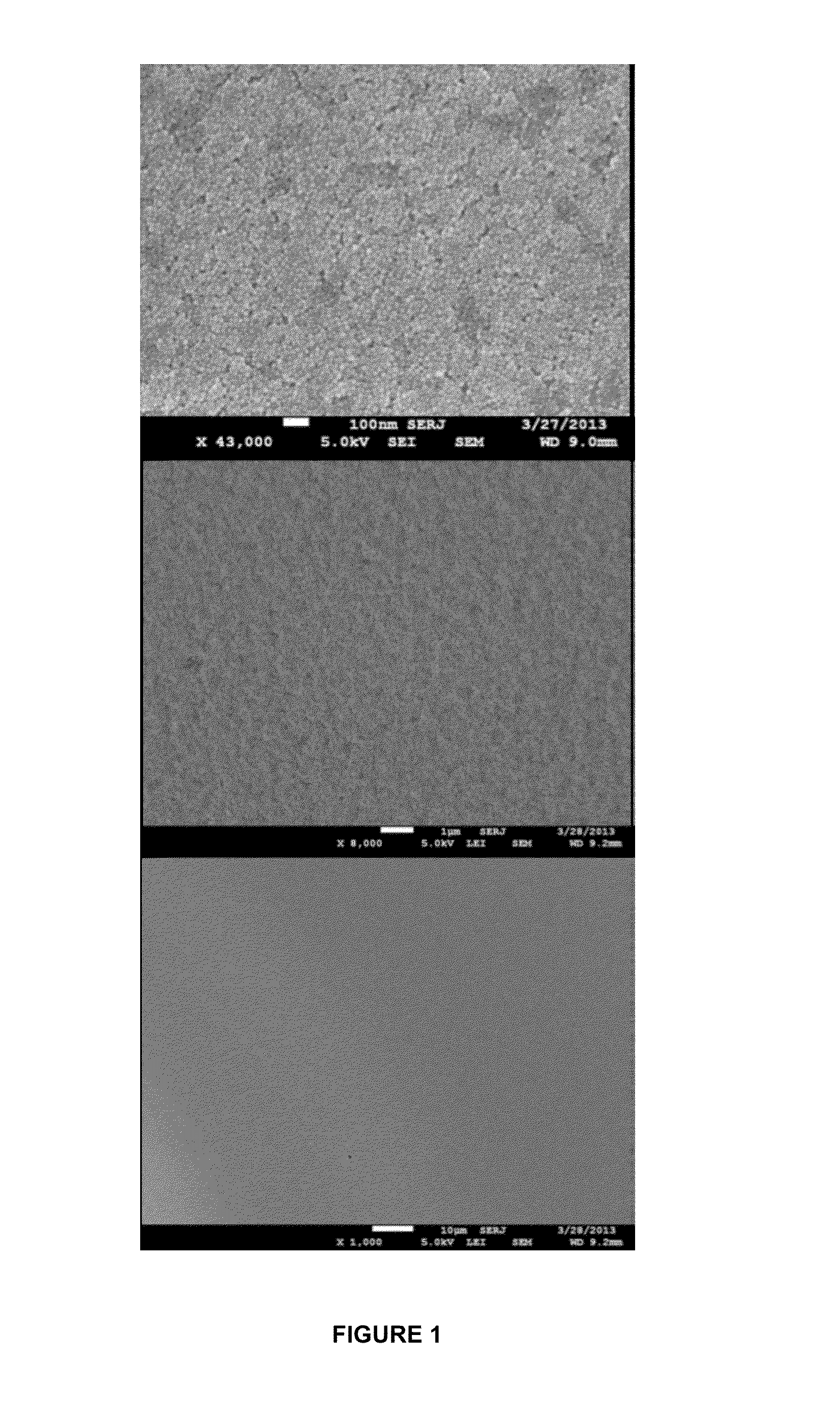

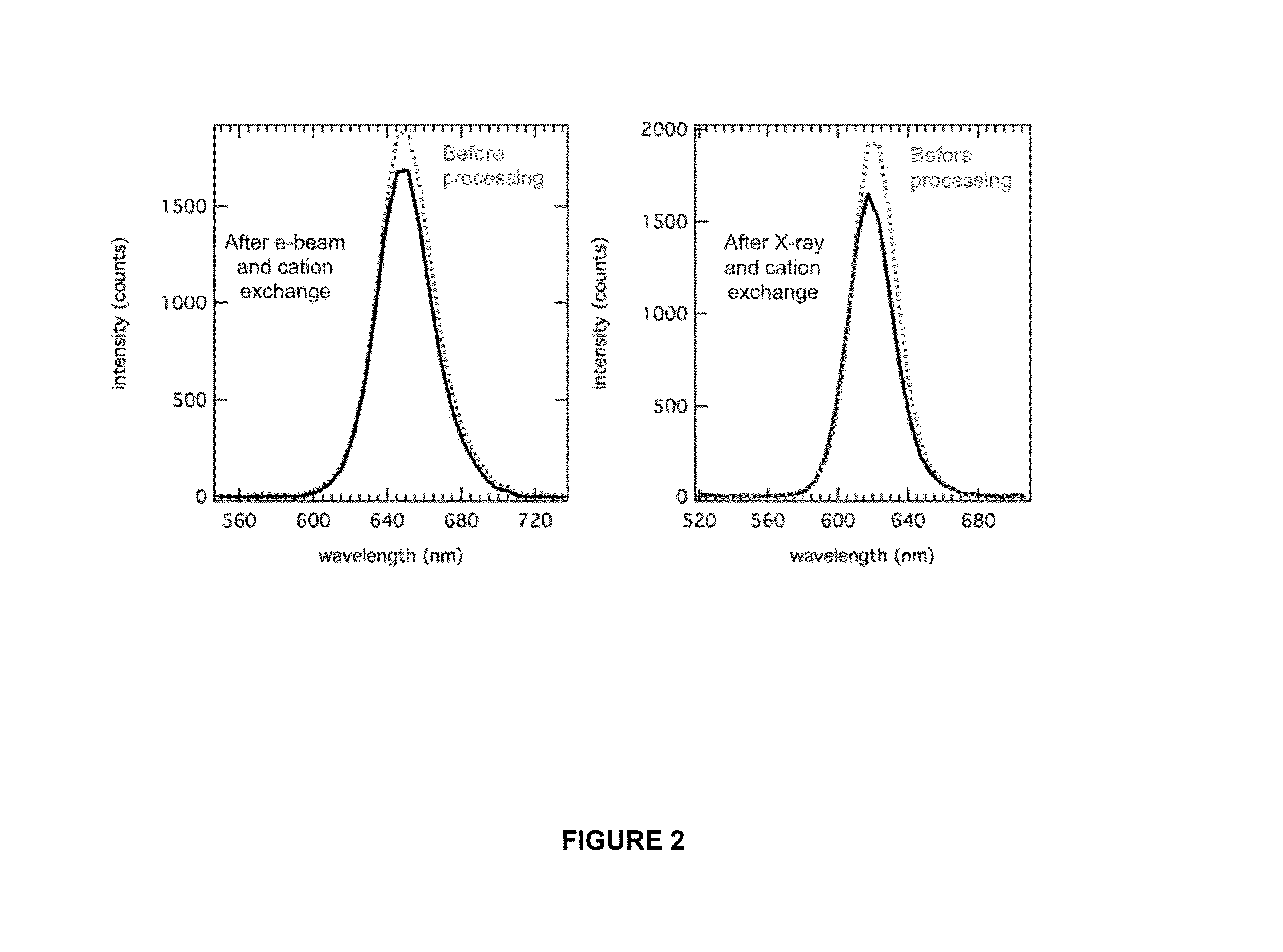

Masked cation exchange lithography

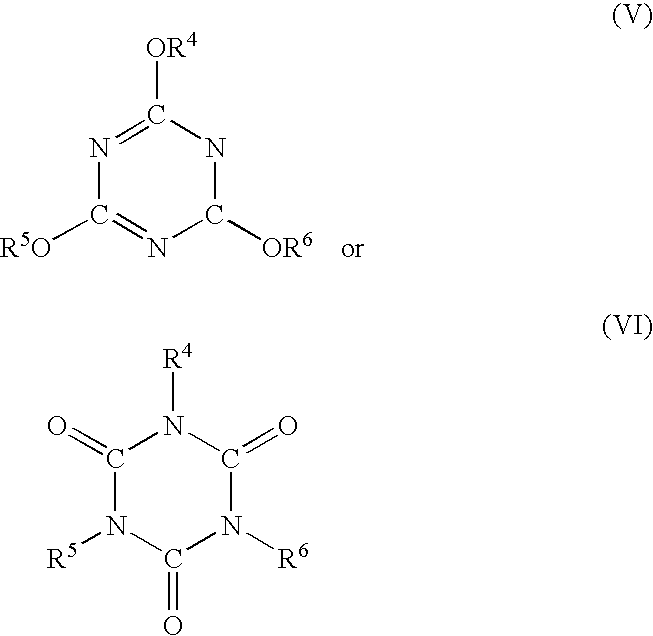

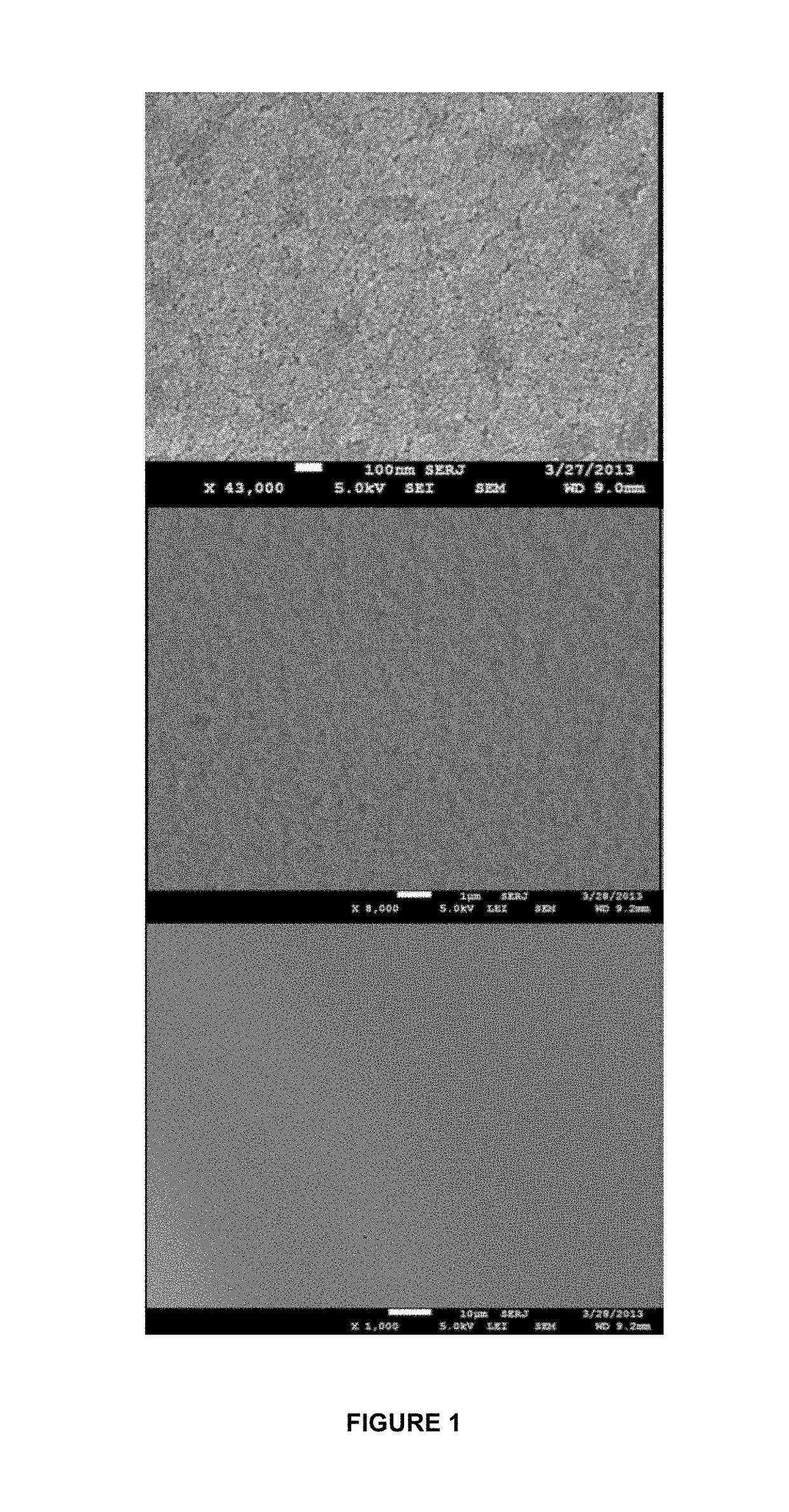

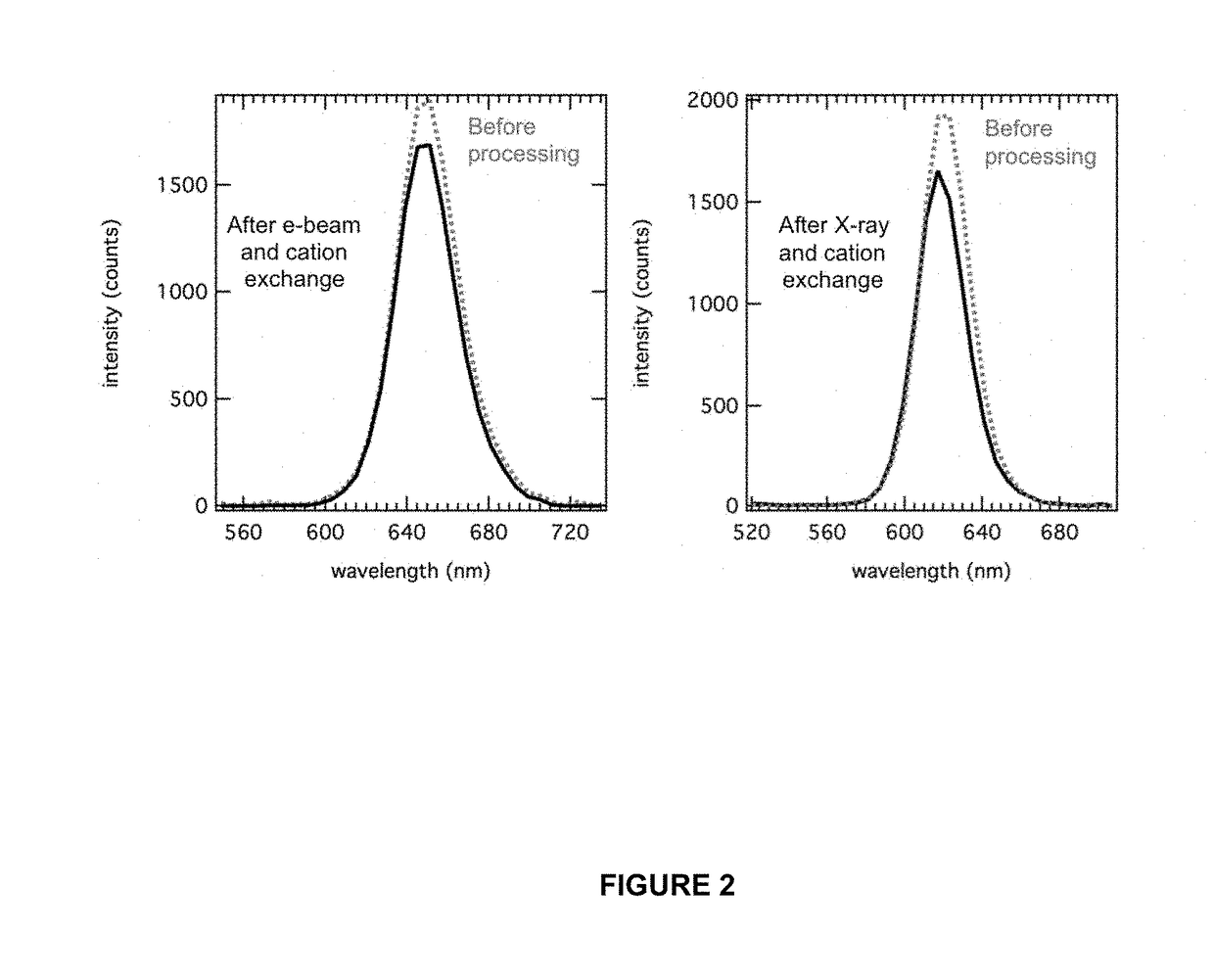

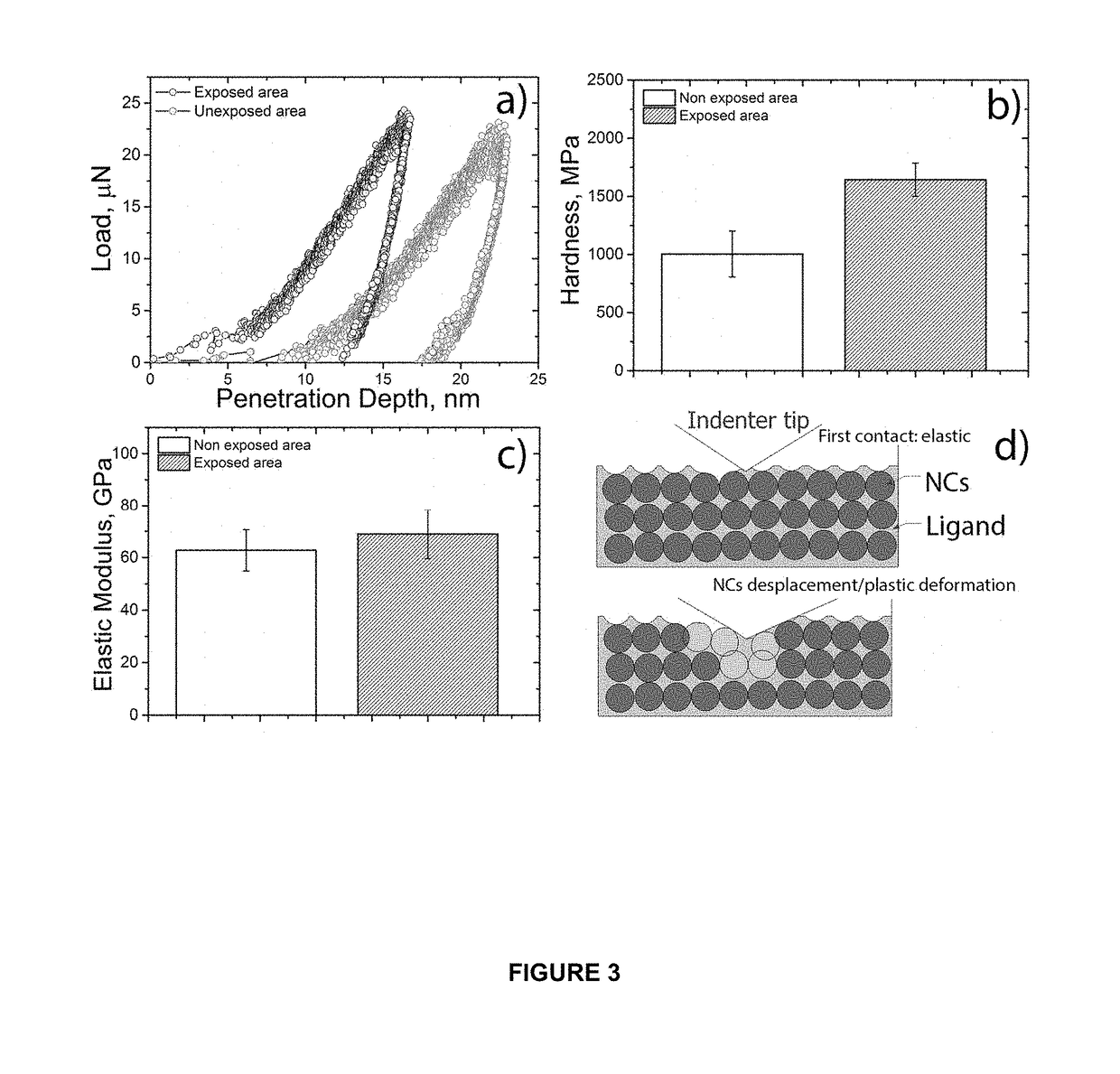

ActiveUS20160246177A1High resolutionNew versatilitySemiconductor/solid-state device manufacturingNanotechnologyCross-linkCation exchange reaction

We describe a method for patterning of colloidal nanocrystals films that combines a high energy beam treatment with a step of cation exchange. The high energy irradiation causes cross-linking of the ligand molecules present at the nanocrystal surface, and the cross-linked molecules act as a mask for the subsequent cation exchange reaction. Consequently, in the following step of cation exchange, the regions that have not been exposed to beam irradiation are chemically transformed, while the exposed ones remain unchanged. This selective protection allows the design of patterns that are formed by chemically different nanocrystals, yet in a homogeneous nanocrystal film.

Owner:FOND INST ITAL DI TECH

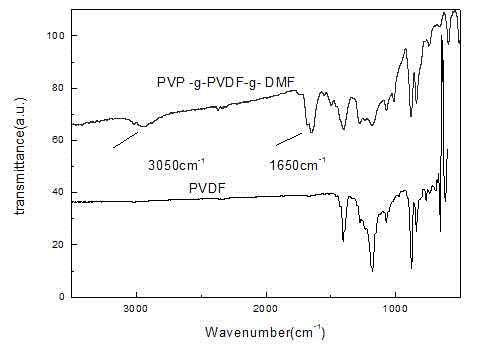

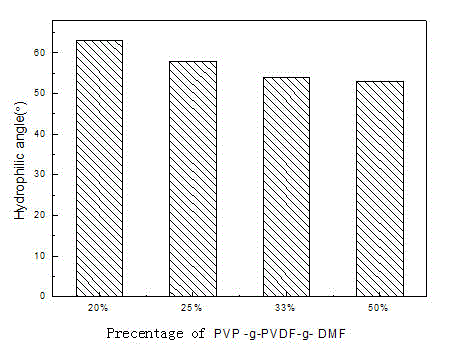

Amphiphilic polymer PVP-g-PVDF-g-DMF and preparation method and application thereof

InactiveCN104945635AImprove hydrophilicityImprove performanceSemi-permeable membranesPolymer scienceN dimethylformamide

The invention discloses an amphiphilic polymer PVP-g-PVDF-g-DMF and a preparation method and application thereof. The amphiphilic polymer PVP-g-PVDF-g-DMF is prepared from PVDF resin which is a main component of a casting solution for a PVDF separation membrane, a super-hydrophilic solvent micromolecular N,N-dimethylformamide (DMF) and a hydrophilic macromolecular pore forming agent polyvinylpyrrolidone (PVP) by a high energy irradiation method; and the amphiphilic polymer can be used for preparing a hydrophilic modified PVDF membrane. The material components used for preparing the amphiphilic polymer are all from a material system for preparing a PVDF separation membrane, and no other substances are added; the obtained modified material system can be directly used without being separated or purified; and the irradiation grafting reaction process is pollution-free and environmentally-friendly, can be performed at room temperature, and is uniform in reaction, simple to operate, stable in process and reliable in quality, thereby being suitable for industrial production.

Owner:HARBIN INST OF TECH

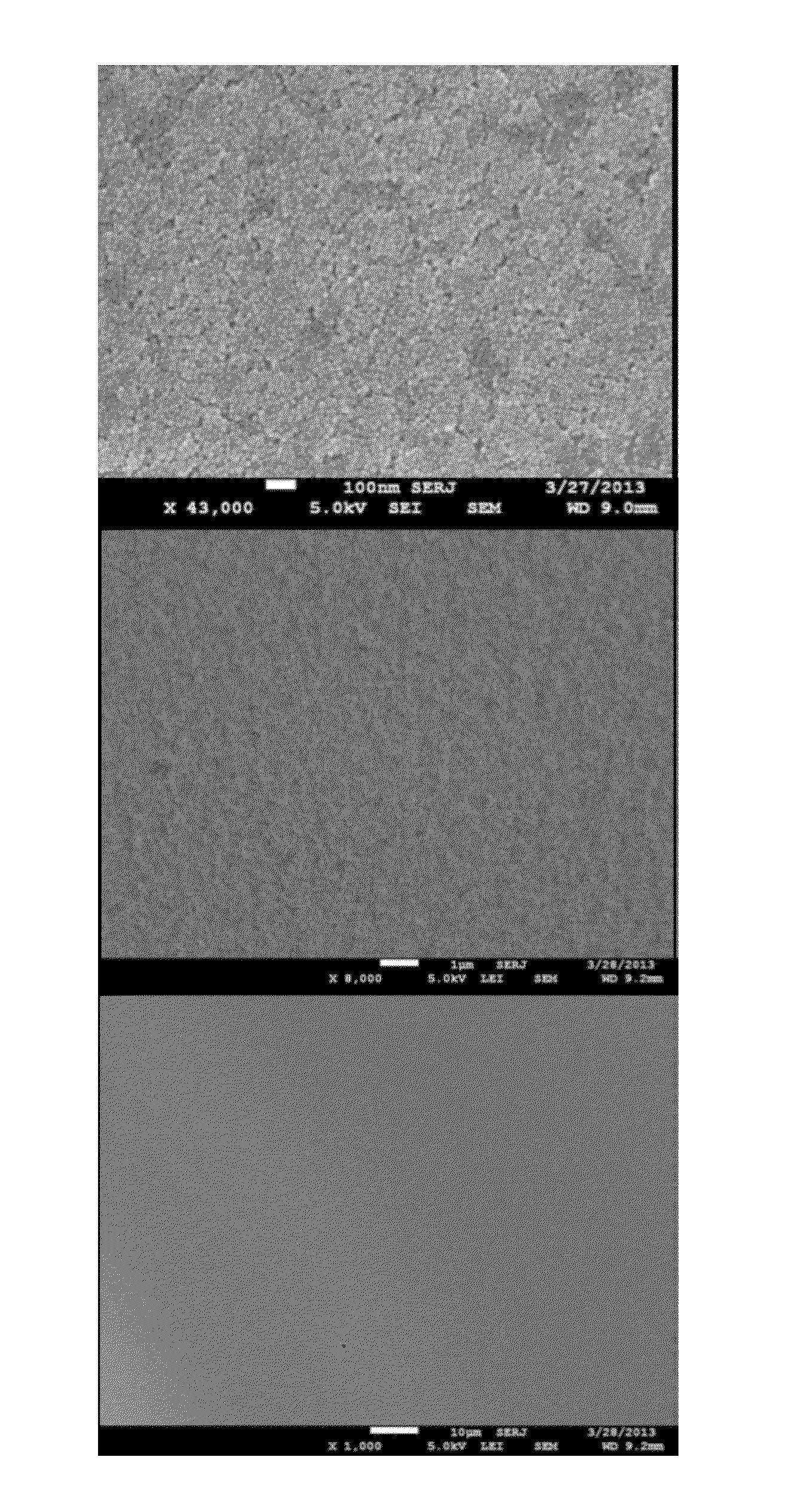

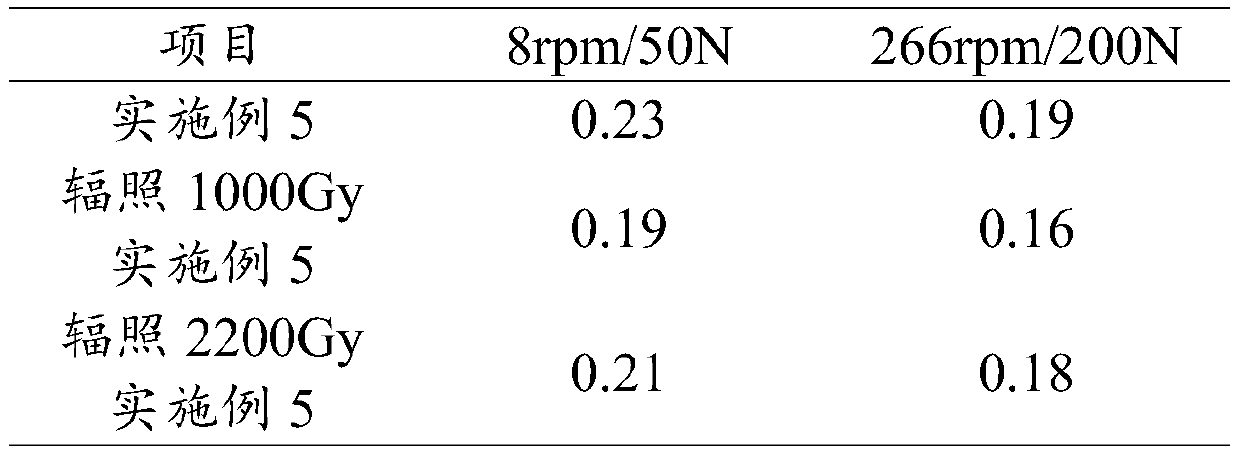

High-energy-irradiation-resistant self-lubricating fabric liner, preparation method and self-lubricating fabric composite material

InactiveCN111270516AExtended service lifeReduce coefficient of frictionSynthetic resin layered productsLight resistant fibresPhysical chemistryGraphene

The present invention provides a high-energy-irradiation-resistant self-lubricating fabric liner, a preparation method and a self-lubricating fabric composite material, and relates to the technical field of functional materials. By taking g-C3N4 and multi-layer graphene as a composite solid lubricant, the requirements of the self-lubricating fabric liner on low friction and abrasion resistance aremet. Meanwhile, the unique six-membered ring structure of the g-C3N4 and multi-layer graphene endows the self-lubricating fabric liner with the certain irradiation resistance, thereby prolonging theservice life of the self-lubricating fabric liner. In addition, by flexible conversion of chemical valence of cerium in cerium dioxide, the irradiation resistance of matrix resin (phenolic resin) is effectively improved. Moreover, the preparation method of the self-lubricating fabric liner is simple, environment-friendly and pollution-free. Furthermore, the self-lubricating fabric composite material formed by the high-energy-irradiation-resistant self-lubricating fabric liner has excellent high energy irradiation resistance and tribology performance.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

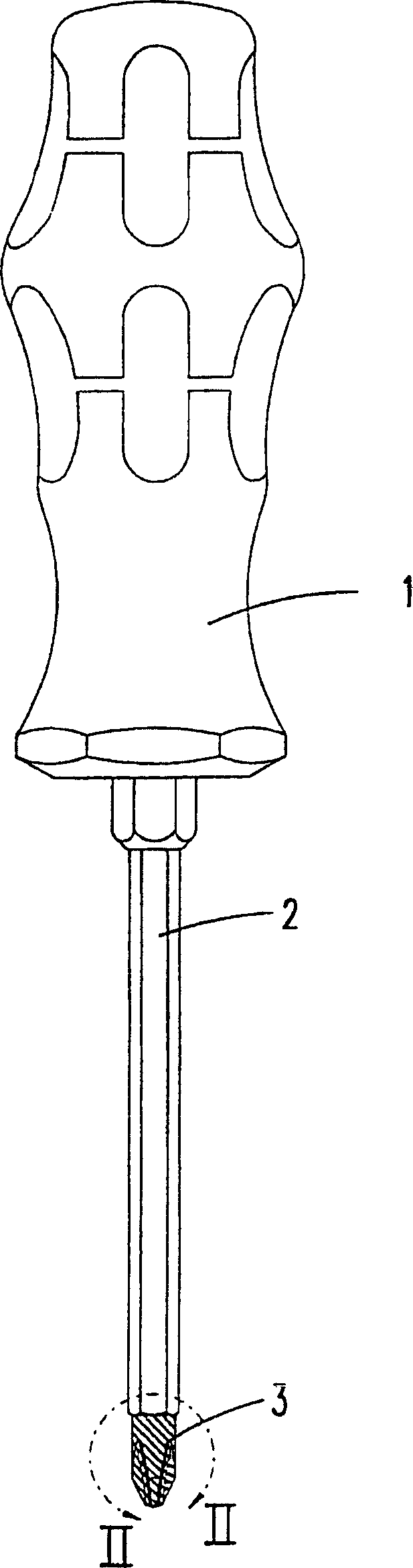

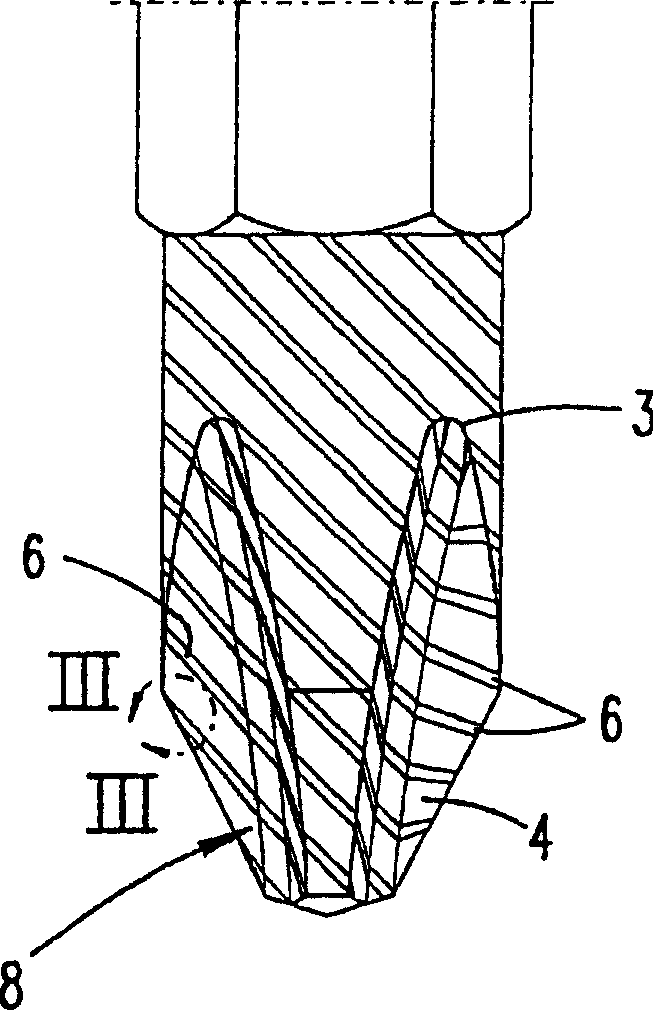

Hand tool, in particular a screwdriver

InactiveCN1214900CImprove wear resistanceAppropriate stiffnessSpannersWrenchesHand toolBiomedical engineering

Owner:WERA WERK HERMANN WERNER GMBH & CO KG

Curable reactive silicone composition, cured product thereof and uses of composition and cured product

ActiveCN113166546AGood formabilityLess prone to cohesive failureNon-macromolecular adhesive additivesVehicle componentsPolymer sciencePtru catalyst

Owner:DOW TORAY CO LTD

Directionally intensified radiation therapy apparatus

InactiveCN1296108CTo achieve the function of stereotaxic therapyTo achieve the effect of intensity modulationSurgical instrument detailsX-ray/gamma-ray/particle-irradiation therapyDiseaseGamma ray

The directional strengthen regulating radiotherapeutic apparatus includes shielding and protecting assembly, focusing units, strengthen regulating board and driving mechanism. The advantage of the present invention is that the independently rotated and focused units may be laid in different angles to focus the dispersive rays, such as gamma rays, onto the disease focus, so that the disease focus obtains high energy irradiation while the health tissue obtains very lower irradiation, reaching stereo directional treatment. By means of the control of the switches and speeds of the focusing units and the strengthen regulating board, the spatial distribution of the dosage absorbed by the disease focus is regulated and the important tissue of the patient may be protected by means of the independent switching function.

Owner:WUHAN KANGQIAO MEDICAL NEW TECH CO LTD

Method for demulsifying emulsion in wastewater

InactiveCN106044942AApplicable treatmentReduce energy consumptionFatty/oily/floating substances removal devicesLiquid separationGlycidyl methacrylateEmulsion

The invention discloses a method for demulsifying emulsion in wastewater; comprising: 1), grafting glycidyl methacrylate to polypropylene nonwoven by means of ultrasonic irradiation or high-energy irradiation within a grafting range of 5%-120%; 2), opening epoxy groups of the glycidyl methacrylate on the surface of the polypropylene nonwoven by using an amine having 4-19 carbons, and constructing hydrophilic and hydrophobic sites on the surface of the polypropylene nonwoven to obtain the modified propylene nonwoven; 3), placing the modified polypropylene nonwoven in emulsion at 10-100 DEG C, stirring for 5-40 min to demulsify the emulsion, wherein a weight ratio of the modified polypropylene nonwoven to the emulsion is 0.01% to 10%. The method has no need for any energy, is low in cost, and is applicable to large-scale wastewater treatment; the method is free of any chemical reagents and is free of other pollutants to a water body.

Owner:TIANJIN POLYTECHNIC UNIV

Process for the preparation of powder coatings

The invention relates to a process of preparation of powder coating compositions providing a desired gloss level of the resulted coatings comprising the following steps of a) providing particles of at least one powder coating composition having a number average particle size in the range of 1 to 300 mum, and b) mixing these particles with particles of at least one powder coating composition having a number average particle size in the range of 1 to 300 mum, the particles of which are irradiated with high energy radiation under near-ambient temperature, in a mixing ratio of 1:99 to 99:1; the process according to the invention provides powder coating compositions producing a desired gloss level of the coatings by varying the time period and / or the intensity of the high energy irradiation of the powder coating particles or by varying the mixing ratio between the non-irradiated powder particles and the irradiated powder particles.

Owner:EI DU PONT DE NEMOURS & CO

Crosslinkable polyamide molding compounds and molded parts produced therewith

InactiveUS8476377B2Improve mechanical propertiesImproved chemicalSynthetic resin layered productsPolyamideDouble bond

The invention relates to crosslinkable, thermoplastic polyamide molding compounds. The polyamides are selected from a group comprising amorphous or microcrystalline polyamides, copolyamides thereof and blends thereof, as well as blends of such polyamides with semicrystalline polyamides. A polyamide molding compound according to the invention is characterized in that it comprises a crosslinking additive which causes the production of crosslinked molded parts formed from said polyamide molding compound under the effect of high-energy irradiation, having a Tg value of >140° C. and a minimum dimensional stability of 90% at temperatures of ≧180° C. These polyamides have a substantially linear structure and the monomers thereof have no olefin C═C double bonds. Corresponding crosslinked polyamide molded parts produced from a polyamide molding compound and the use of this polyamide molding compound to produce these crosslinked polyamide molded parts are additionally disclosed.

Owner:EMS PATENT AG

Masked cation exchange lithography

ActiveUS10160906B2New versatilityHigh resolutionSemiconductor/solid-state device manufacturingNanotechnologyCross-linkCation exchange reaction

We describe a method for patterning of colloidal nanocrystals films that combines a high energy beam treatment with a step of cation exchange. The high energy irradiation causes cross-linking of the ligand molecules present at the nanocrystal surface, and the cross-linked molecules act as a mask for the subsequent cation exchange reaction. Consequently, in the following step of cation exchange, the regions that have not been exposed to beam irradiation are chemically transformed, while the exposed ones remain unchanged. This selective protection allows the design of patterns that are formed by chemically different nanocrystals, yet in a homogeneous nanocrystal film.

Owner:FOND INST ITAL DI TECH

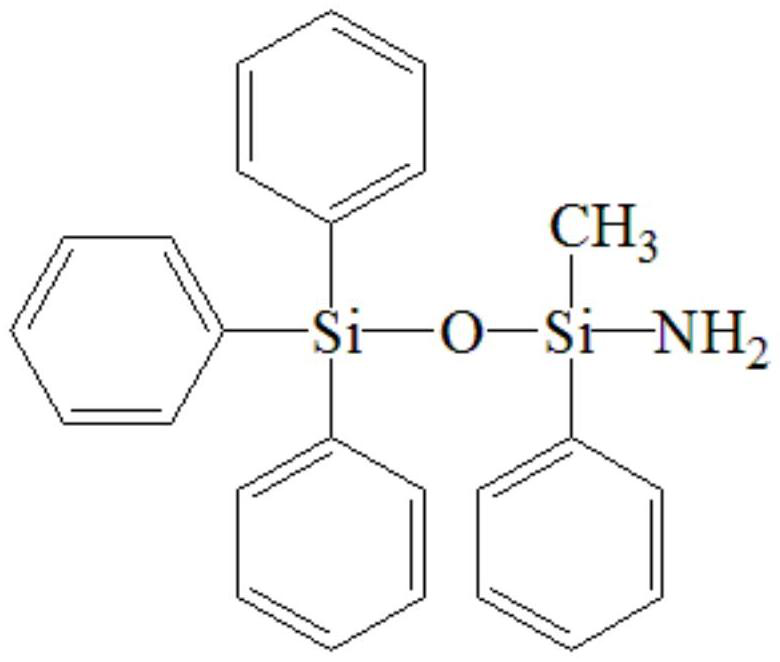

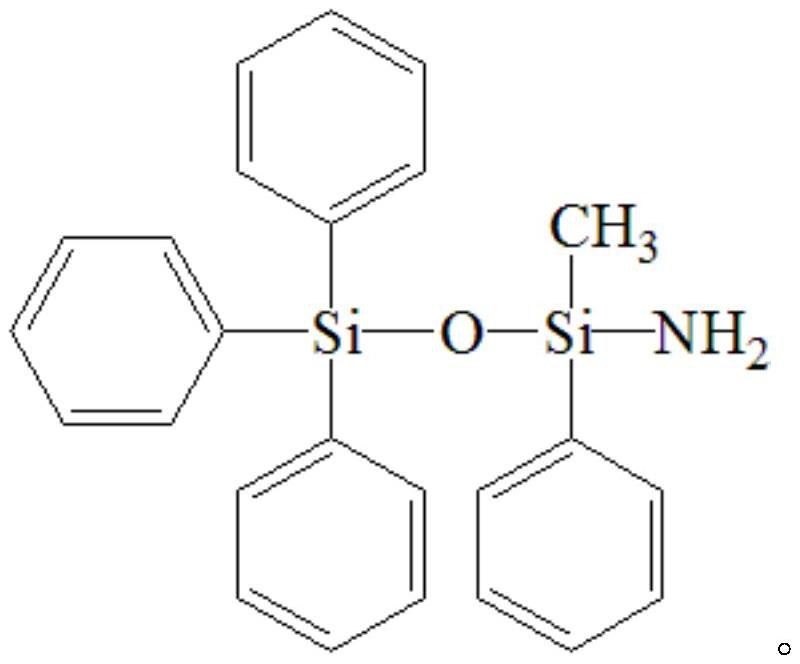

Radiation-resistant additive and method for synthesizing and preparing radiation-resistant silicone rubber material

ActiveCN110128461BImprove radiation resistanceGood compatibilityGroup 4/14 element organic compoundsPolymer scienceVulcanization

Owner:BAIMTEC MATERIAL CO LTD

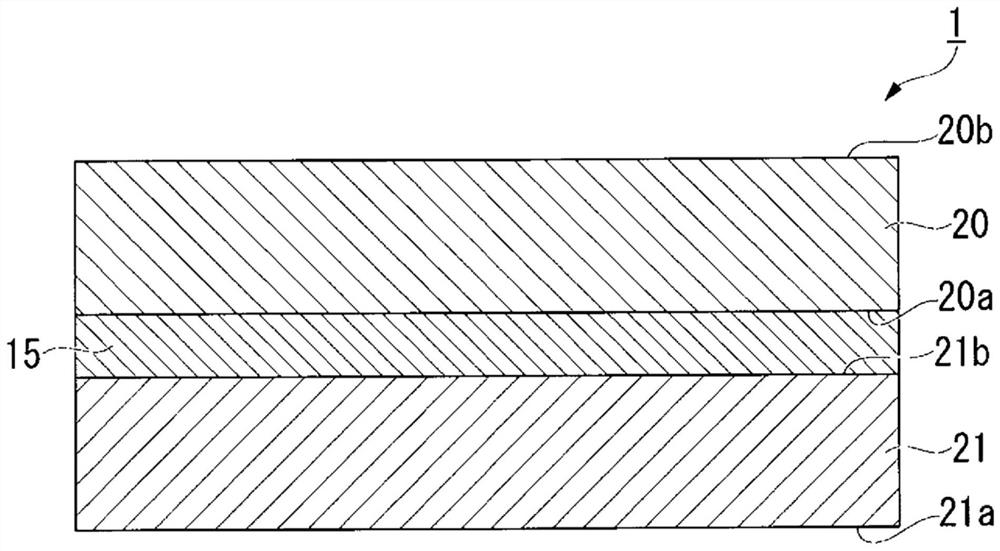

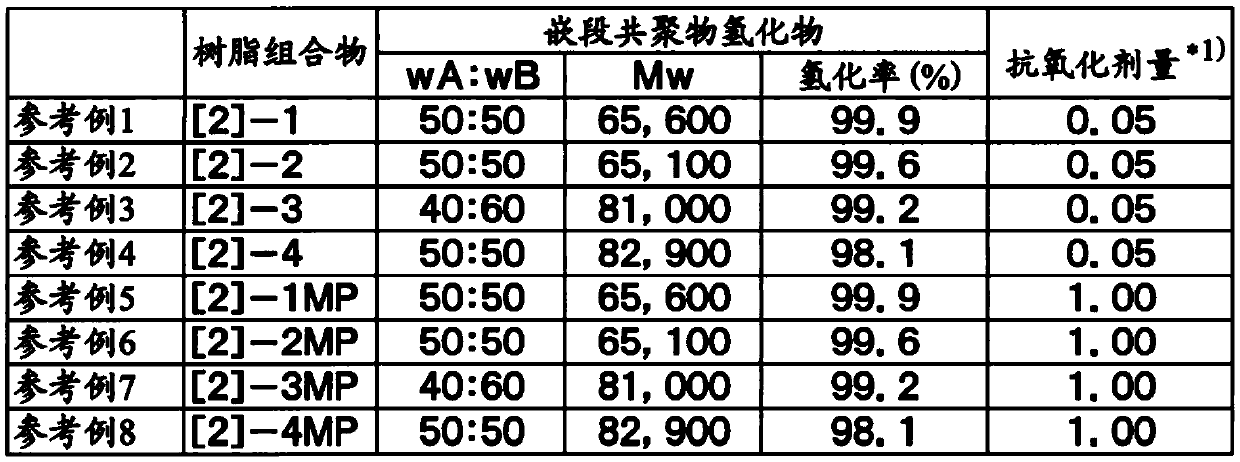

Method for producing sterilized medical molded body

A method for producing a sterilized medical molded body by high energy irradiation of the medical molded body with an exposure dose E, the medical molded body being formed from a resin composition comprising: 100 parts by weight of a block copolymer hydride in which 99% or more of the total unsaturated bond of a block copolymer is hydrogenated, the block copolymer comprising a polymer block (A) that is composed mainly of a unit derived from an aromatic vinyl compound and a polymer block (B) that is composed mainly of a unit derived from a chain conjugated diene compound with a ratio of the weight fraction of the polymer block (A) and the polymer block (B) being 30:70 to 70:30; and a phenolic antioxidant in an amount of parts by weight represented by formula 1: W=[0.46x(100-H)+0.04]x(E / 25) (In the formula, W is the parts by weight of the antioxidant with respect to 100 parts by weight of the block copolymer hydride, H is a hydrogenation degree of the block copolymer hydride indicated in % units, H is a numerical value of 99 to 100, and E is an exposure dose of high energy rays indicated in kGy units) or more and 0.50 parts by weight or less.

Owner:ZEON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com