Method for preparing functionalized graphene based on high-energy irradiation one-step method

An irradiation and functional technology, which is applied in the field of one-step preparation of functionalized graphene based on high-energy irradiation, can solve the problems of easily damaged graphene structure, and achieve the effects of strong penetrating power, low cost and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

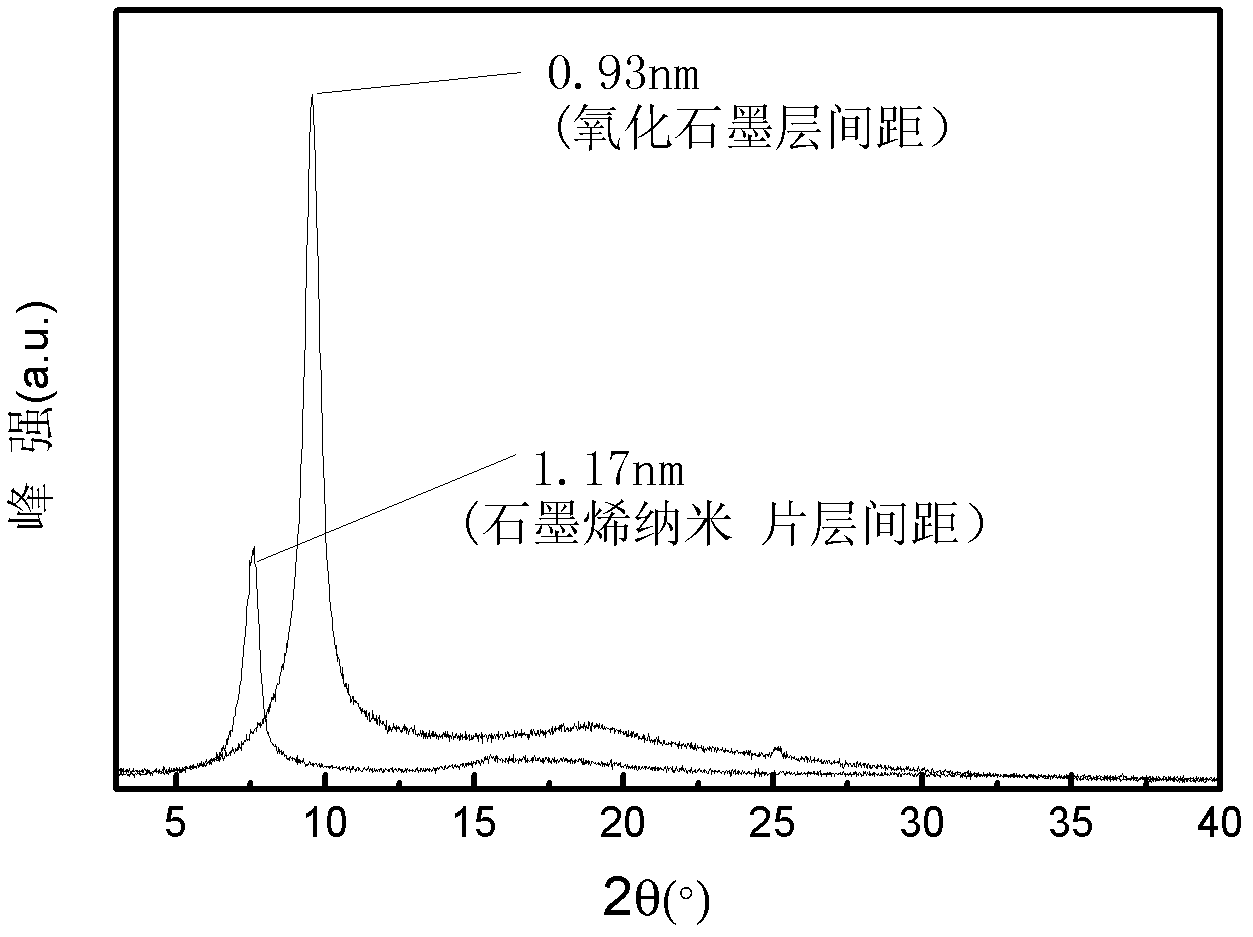

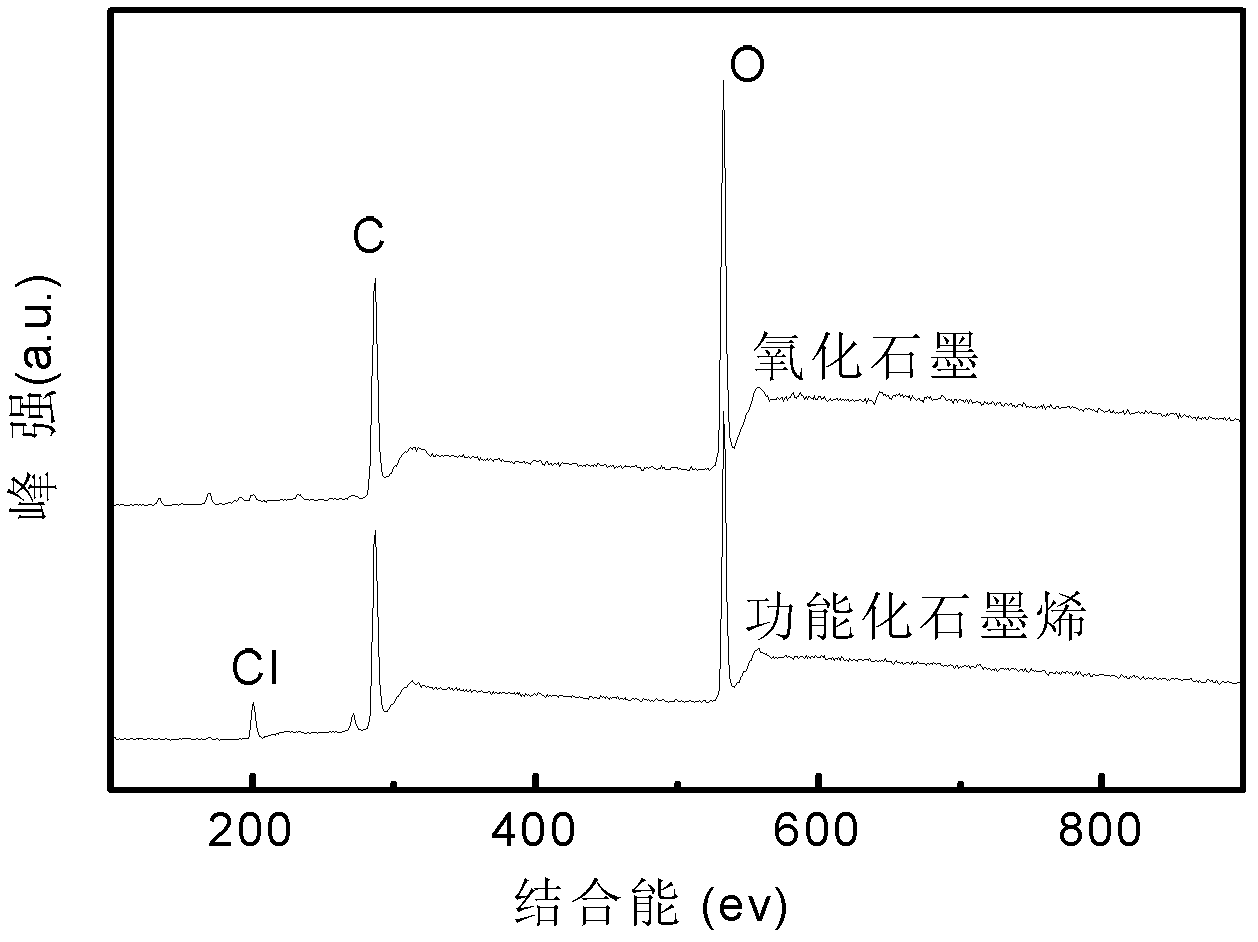

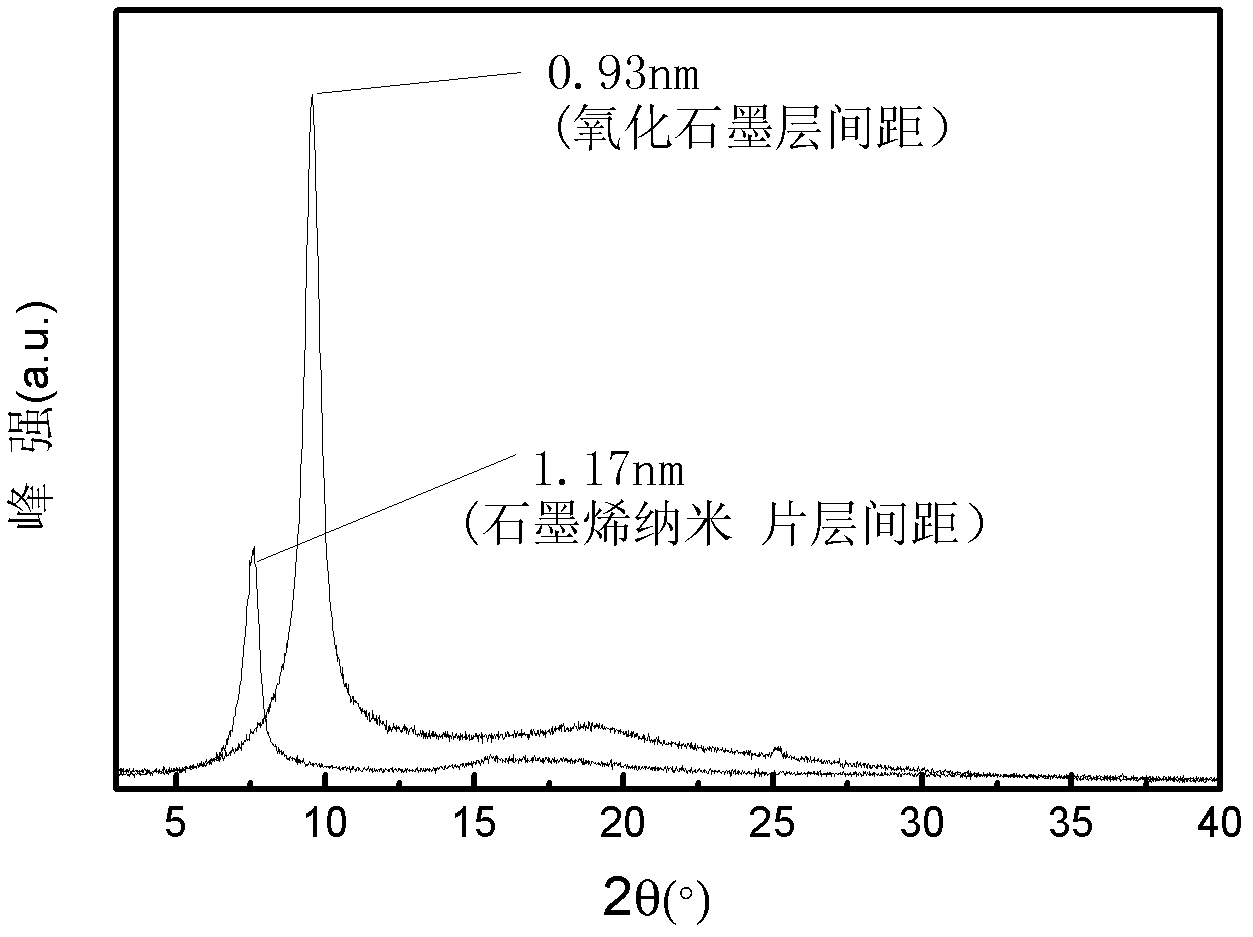

[0015] Dry the graphite oxide powder prepared according to the method described in the document "Improved Synthesis of Graphene Oxide" to obtain graphite oxide powder, take 50 mg of the prepared graphite oxide powder, and add it to a glass bottle containing 50 mL of epichlorohydrin reagent , the mixed solution was ultrasonically dispersed for 1 hour, and then the glass bottle containing the above dispersion was placed in 60 In the γ-ray irradiation room of Co, the irradiation dose rate is 2.0×10 3 Gy / h, the irradiation dose is 2×10 5 Under the condition of Gy, γ-ray irradiation is carried out, the irradiation time is 100 hours, and the irradiation temperature is room temperature, so that the surface of graphite oxide is peeled off to form graphene nanosheets. The above-mentioned obtained graphene nanosheets were analyzed by X-ray diffraction (XRD) and X-ray photoelectron spectroscopy, and compared with graphite oxide before irradiation, the results are as follows: figure 1 ,...

Embodiment 2

[0017] The graphite oxide powder prepared according to the method described in the document "Improved synthesis of graphene oxide" was dried to obtain graphite oxide powder, and 40 mg of the prepared graphite oxide powder was added to a 100 mL styrene / acetone solution (50 wt % ) in a glass bottle, the mixed solution was ultrasonically dispersed for 2 hours, and then the glass bottle containing the above dispersion was placed in 60 In the γ-ray irradiation room of Co, the irradiation dose rate is 1.0×10 3 Gy / h, the irradiation dose is 5×10 5 Under the condition of Gy, γ-ray irradiation is carried out, the irradiation time is 500 hours, and the irradiation temperature is 50° C., so that the surface of graphite oxide is peeled off to form graphene nanosheets. According to XRD analysis and XPS elemental analysis, styrene has been successfully grafted onto the surface of graphite oxide, and functionalized graphene nanosheets were obtained by exfoliation.

Embodiment 3

[0019] Dry the graphite oxide powder prepared according to the method described in the document "Improved synthesis of graphene oxide" to obtain graphite oxide powder, take 100 mg of the prepared graphite oxide powder, and add it to a container containing 100 mL of acrylic acid / water solution (10 wt %) In a glass bottle, the mixed solution was ultrasonically dispersed for 2 hours, and then the glass bottle containing the above dispersion was placed in 60 In the γ-ray irradiation room of Co, the irradiation dose rate is 2.0×10 3 Gy / h, the irradiation dose is 3×10 4 Under the condition of Gy, γ-ray irradiation is carried out, the irradiation time is 15 hours, and the irradiation temperature is 40° C., so that the surface of graphite oxide is exfoliated to form graphene nanosheets. According to XRD analysis and XPS elemental analysis, acrylic acid has been successfully grafted onto the surface of graphite oxide, and functionalized graphene nanosheets were obtained by exfoliation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com