Temporary protection coating for UV illumination demolding and application of temporary protection coating

A temporary protection and coating technology, applied in the field of coatings, can solve the problems of easy generation of copper chips and affecting drilling accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

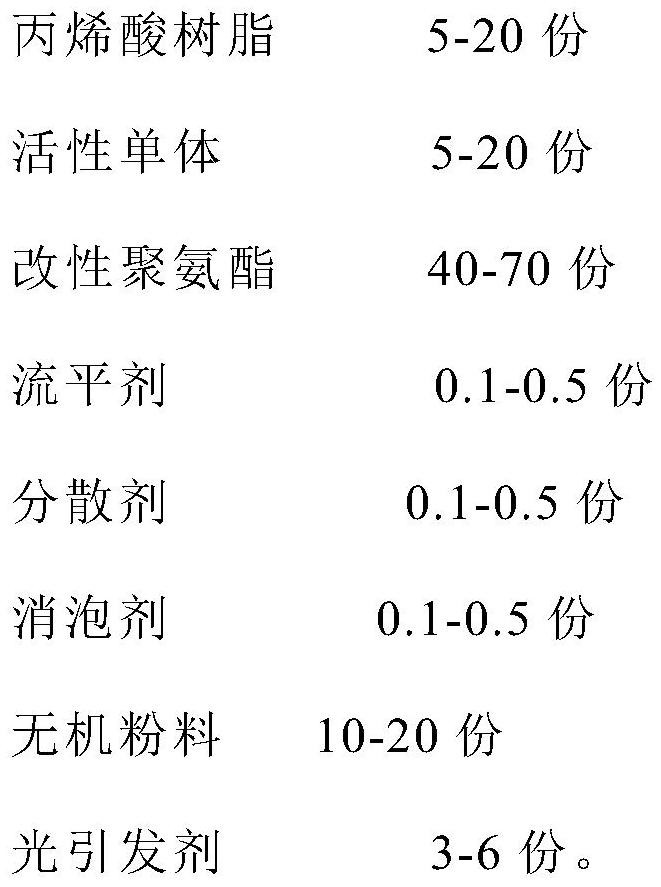

[0035] The invention provides a temporary protective coating for UV light stripping, which comprises the following components in parts by weight:

[0036]

Embodiment 2

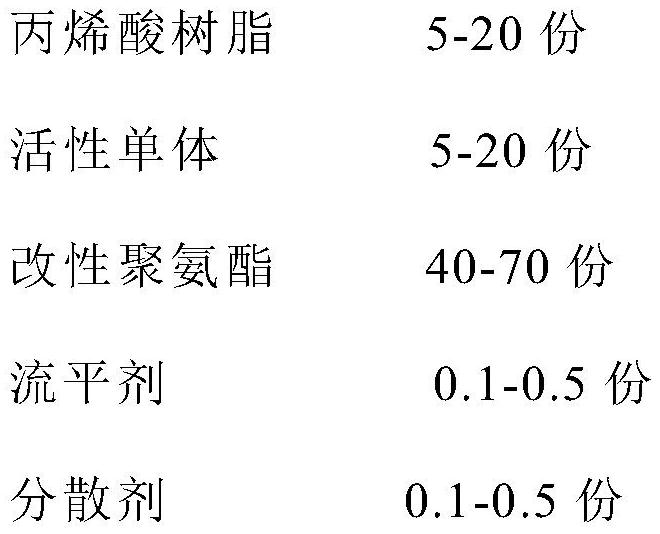

[0038] The invention provides a temporary protective coating for UV light stripping, which comprises the following components in parts by weight:

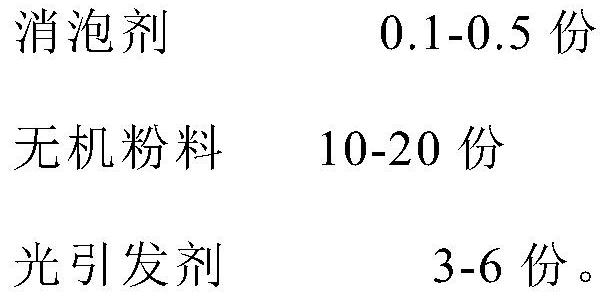

[0039]

[0040]

Embodiment 3

[0042] The invention provides a temporary protective coating for UV light stripping, which comprises the following components in parts by weight:

[0043]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com