Optical cable preparation method capable of reducing optical cable wind pressure and optical cable

A technology of optical cable and wind pressure, applied in the field of optical cable preparation, can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

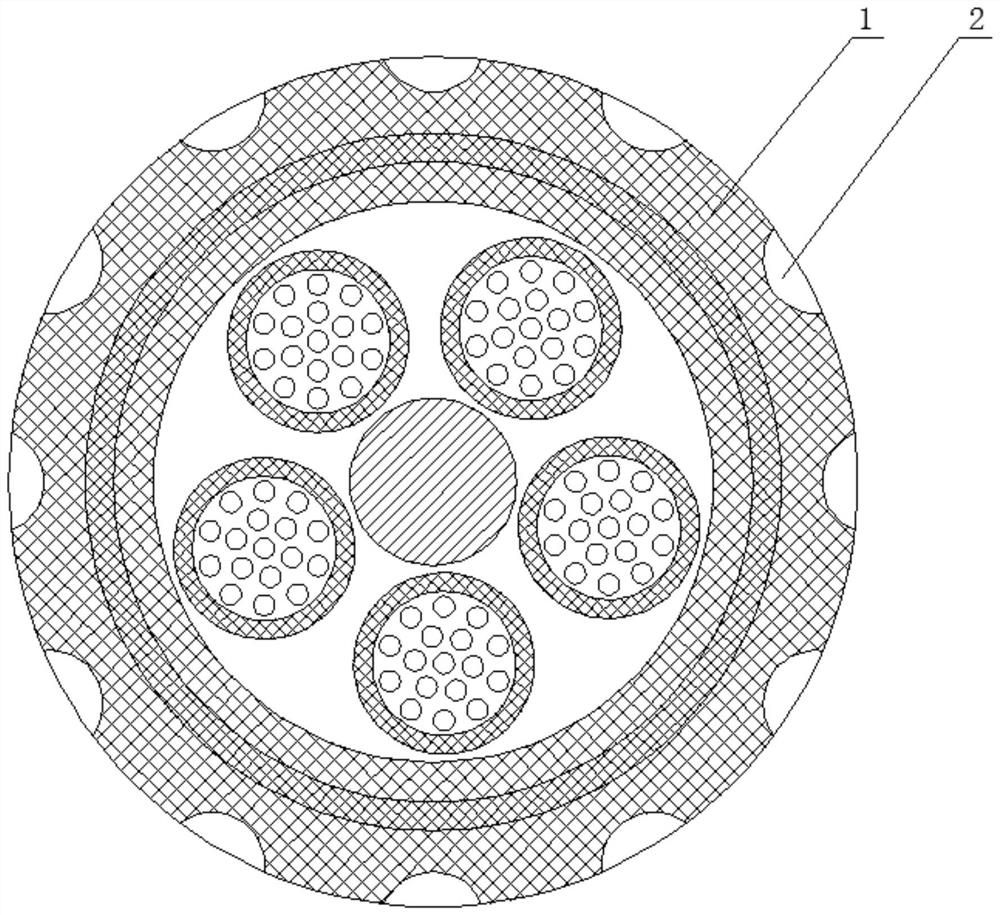

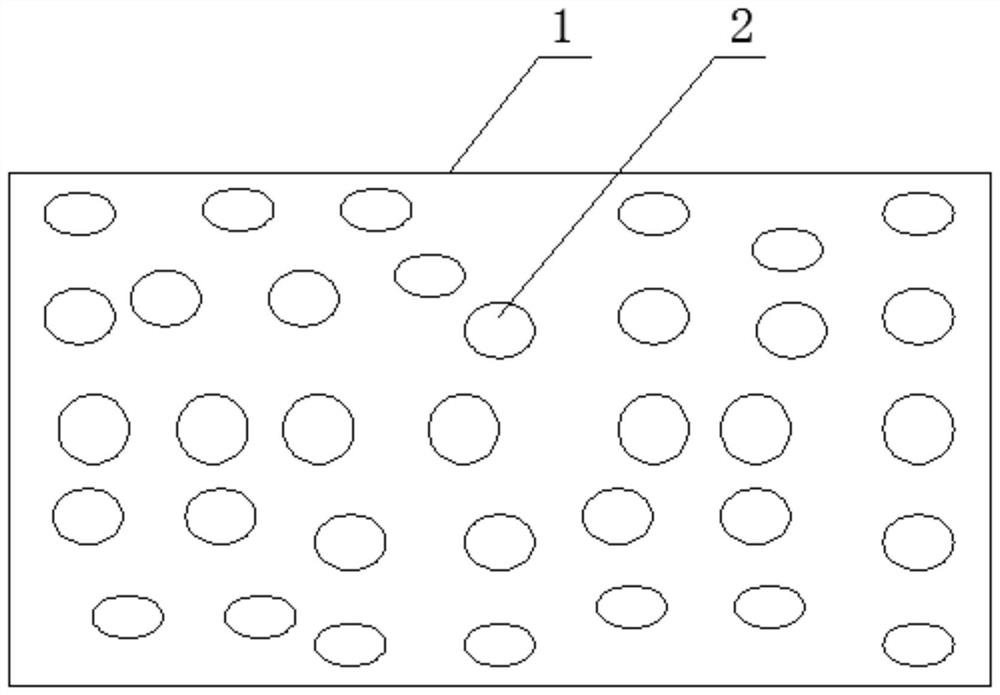

[0027] An optical cable preparation method that can reduce the wind pressure of the optical cable, the optical cable preparation method includes an extrusion step of obtaining a sheath 1 outside the cable core by extrusion; it also includes the use of a coolant contained in a cooling tank after the extrusion step , the cooling step of cooling the formed sheath 1, in the cooling step, using the waste heat of the sheath 1 to form and attach air bubbles to the local surface of the sheath 1, under the action of the air bubbles, This allows the sheath 1 to cool while passing through the cooling slot.

[0028] For the preparation of optical cables, the prepared cable core passes through the extrusion head of the extruder, and an annular extrusion hole is set on the periphery of the cable core, through which the cable core is extruded to the side of the cable core to form an optical cable The high-temperature melting material of the sheath 1, the more common materials are polyethylen...

Embodiment 2

[0031] This embodiment is further introduced on the basis of Embodiment 1: as mentioned above, in the process of the existence of air bubbles, the cooling that actually occurs on the surface of the sheath 1 is non-uniform cooling, so in order to improve the production efficiency of the optical cable, it is set as : After the preliminary cooling is completed in the presence of air bubbles, the air bubbles are removed, so that the sheath 1 is further cooled to a rollable state. The above further cooling can be cooled by cooling water.

Embodiment 3

[0033] This embodiment is further introduced on the basis of Example 1: as one of the specific ways to obtain air bubbles, the air bubbles are obtained by raising the temperature of the coolant, after the sheath 1 enters the coolant , using the waste heat of the sheath 1 to obtain the air bubbles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com