Pulse arc welding control method

A control method and pulsed arc technology, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of large external inductance value and failure to maintain waveform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

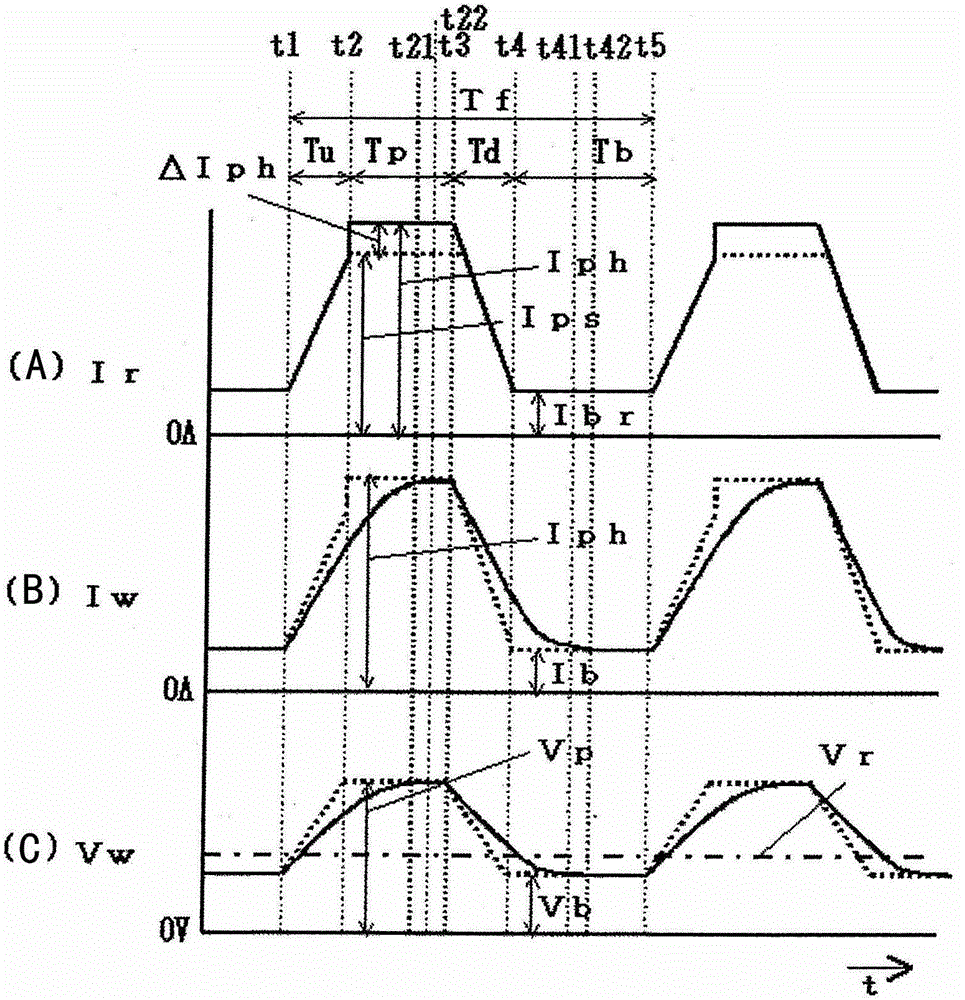

[0081] figure 1 It is a current and voltage waveform diagram showing the pulse arc welding control method according to the embodiment of the present invention when the external inductance value is large. The graph (A) shows the time change of the welding current setting signal Ir, the graph (B) shows the temporal change of the welding current Iw, and the graph (C) shows the temporal change of the welding voltage Vw. Since the external inductance value is large, this figure is a case where the rising speed Bd of the welding current Iw in the peak rising period Tu is lower than the reference speed Bt. This figure corresponds to the above Figure 5 . In this figure, the standard peak current setting Ips vs. Figure 4 as well as Figure 5 The peak current setting value Ipr is the same value. Hereinafter, description will be made with reference to this figure.

[0082...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com