Peroxidated heat-vulcanized silicone rubber resistant to irradiation and preparation method thereof

A thermally vulcanized silicone rubber, radiation-resistant technology, applied in the field of thermally vulcanized silicone rubber, high-strength peroxidized thermally vulcanized silicone rubber and its preparation, can solve the problems of cumbersome preparation process and complex rubber components, and achieve environmental adaptation Strong performance, good social and economic benefits, and good γ-ray absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

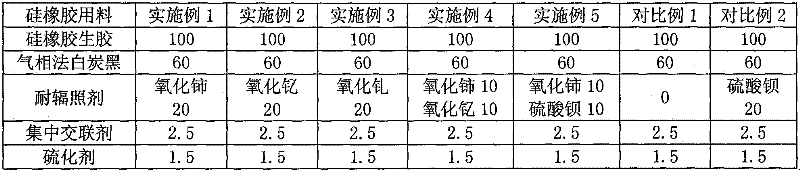

Embodiment 1

[0027] Weigh the following components in parts by weight (kg): 100 parts of silicone rubber raw rubber (methyl vinyl silicone rubber, whose vinyl content is 0.01%-0.1% by weight, molecular weight above 500,000), anti- 20 parts of irradiation agent (cerium oxide), 60 parts of fumed silica (TS530 produced by Cabot Corporation of the United States), concentrated crosslinking agent (viscosity 1500mm 2 / s, 2.5 parts of polyvinyl silicone oil with Vi weight ratio content of 11.5%, 1.5 parts of vulcanizing agent (2,5-dimethyl-2,5-di-tert-butylperoxyhexane).

[0028] Firstly add the raw silicone rubber, fumed white carbon black and anti-radiation agent in the amount of components to the mixer in sequence, mix at room temperature for 30 minutes, then heat-treat the mixed material at 160°C for 1 hour, Then cool it down to room temperature, add the concentrated cross-linking agent and vulcanizing agent of the component amount, and then knead evenly to obtain a peroxidized heat-vulcanized...

Embodiment 2

[0030] The specific operation method is the same as that of Example 1, except that cerium oxide is replaced by yttrium oxide in the distribution ratio of the radiation-resistant agent components.

Embodiment 3

[0032] The specific operation method is the same as that of Example 1, except that cerium oxide is replaced by gadolinium oxide in terms of the ratio of the radiation-resistant agent components.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com