Amphiphilic polymer PVP-g-PVDF-g-DMF and preparation method and application thereof

An amphiphilic polymer, pvp-g-pvdf-g-dmf technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of pollution, difficult to control, easy to be washed off, etc. , to achieve the effect of stable process, reliable quality and uniform response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

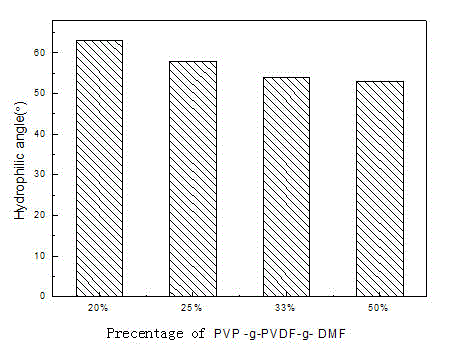

[0035] Embodiment 1: According to the ratio of mass parts PVDF:PVP:DMF=50:7-15:150-170, add PVDF resin powder and PVP powder into DMF solvent for mixing, and heat to 60 under sealed stirring condition -80°C, keep the constant temperature for 8-12 hours to completely dissolve the material mixture into a uniform solution, keep it in a sealed state and cool to room temperature, then use it as a radiation grafting system for gamma-ray irradiation treatment. Adopt one-step irradiation method to complete the irradiation grafting treatment according to the irradiation dose of 25.0 kGy and the irradiation dose rate of 6.0 KGy / h, and obtain modified materials containing the target product PVP-g-PVDF-g-DMF and its unreacted DMF system. Mix the grafted reaction material after irradiation treatment with the film-casting solution of unmodified PVDF resin according to the mass ratio of 10-50:100 to prepare a composite film-making solution. The casting solution was used for film formation, ...

specific Embodiment approach 2

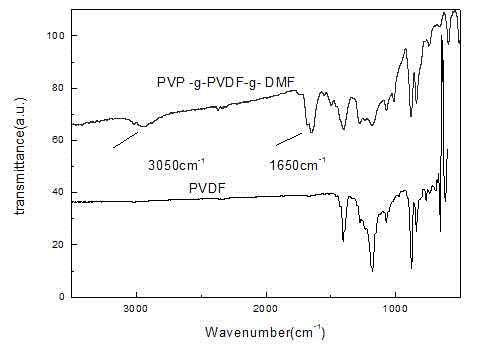

[0039] Specific embodiment two: the difference between this embodiment and specific embodiment one is: two-step irradiation treatment is adopted, the irradiation dose of the first step irradiation grafting treatment is 5.0-10.0 kGy, and the irradiation dose rate is 5.0-5.5 KGy / h, this process is to realize the grafting reaction of PVDF and DMF to obtain the pre-product PVDF-g-DMF; on this basis, the second step of irradiation treatment is carried out, the irradiation dose is 7.5-18.0 kGy, and the irradiation dose rate is 6.6-7.5 KGy / h, this process is to realize the grafting reaction of the pre-product PVDF-g-DMF and PVP to form the double-grafted product PVP-g-PVDF-g-DMF. From the graft reaction material system after irradiation treatment, a small part is taken out for separation and purification to obtain the pure target product PVP-g-PVDF-g-DMF, and the infrared spectrum analysis of the product structure is shown in figure 1 , compared with the spectrum of unmodified pure P...

specific Embodiment approach 3

[0040] Specific embodiment three: the difference between this embodiment and specific embodiment one is: the components in the grafting system of specific embodiment one are prepared according to the following proportions to prepare two grafting systems, and grafting system 1 is composed of PVDF and DMF. Component composition, PVDF:DMF= 25:75-85, graft system 2 is composed of PVDF, PVP and DMF three components, PVDF:PVP:DMF= 25:7-15:75-85, using two-step radiation According to the treatment method, the first step is to irradiate the graft system 1, the irradiation dose is 5.0-10.0 kGy, and the irradiation dose rate is 5.0-5.5 KGy / h. This process is to realize the grafting reaction of PVDF and DMF to obtain Pre-product PVDF-g-DMF; the graft system 1 and graft system 2 after the first step of irradiation treatment are mixed evenly for the second step of irradiation treatment, the irradiation dose is 7.5-18.0 kGy, and the irradiation dose rate is 6.6-7.5 KGy / h, this process is to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com