High-energy-irradiation-resistant self-lubricating fabric liner, preparation method and self-lubricating fabric composite material

A self-lubricating, fabric technology, used in chemical instruments and methods, textiles and papermaking, synthetic resin layered products, etc. The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

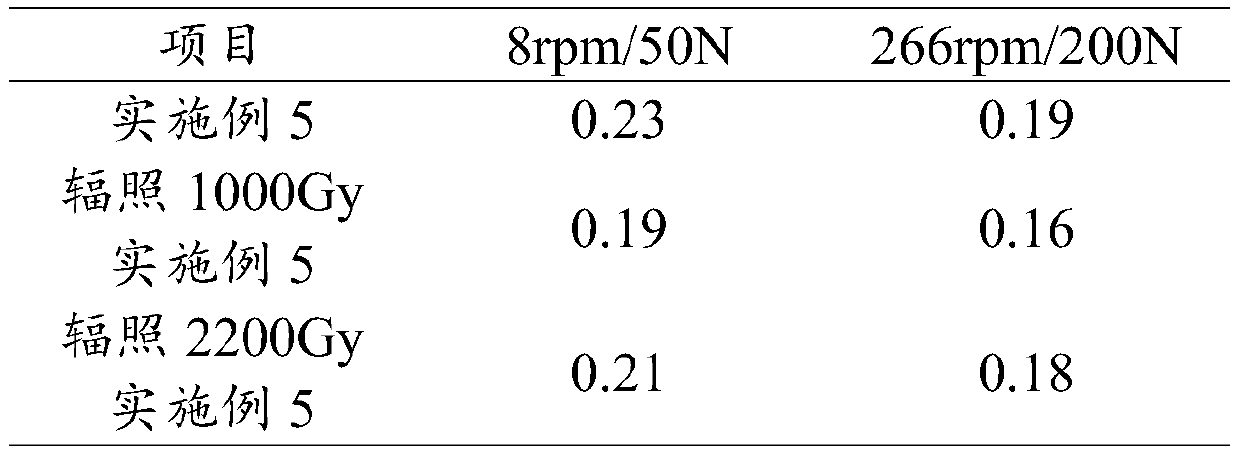

Examples

preparation example Construction

[0039] The present invention also provides a preparation method of the anti-high energy radiation self-lubricating fabric liner described in the above technical solution, comprising the following steps:

[0040] mixing and dispersing the composite solid lubricant, cerium oxide, phenolic resin adhesive and diluent to obtain a self-lubricating dipping solution;

[0041] The self-lubricating impregnation solution is applied to the pretreated blended fiber cloth and dried to obtain the high-energy radiation-resistant self-lubricating fabric pad.

[0042] The invention mixes and disperses the composite solid lubricant, cerium oxide, phenolic resin adhesive and diluent to obtain a self-lubricating dipping solution.

[0043] In the present invention, the method of obtaining the composite solid lubricant is consistent with the above technical solution, and will not be repeated here.

[0044] In the present invention, the phenolic resin adhesive is preferably a phenolic-nitrile adhesi...

Embodiment 1

[0061] 1. Dissolve 8g of 3,4-dihydroxyphenylethylamine and 6g of tris(hydroxymethyl)aminomethane in 140g of deionized water to obtain a mixed solution; soak the blended fiber cloth in the mixed solution for pretreatment for 60min, and take it out at 100°C Dried for 24 hours in a blast oven to obtain a pretreated blended fiber cloth;

[0062] 2. Add 10gg-C 3 N 4 After mixing with 10 g of multilayer graphene ball mill for 8 hours, take it out and wash it twice with ethanol, and then dry it at 80°C for 10 hours to obtain a composite solid lubricant;

[0063] 3. 10g phenolic-nitrile adhesive (solid content 75%), 0.11g nanometer CeO 2 And 1.875g of the composite solid lubricant prepared in step 2 is dispersed in 35.5g of ethyl acetate, fully mixed at a speed of 10000r / min in a high-speed dispersing emulsifier to obtain a self-lubricating impregnation solution;

[0064] 4. Apply the self-lubricating impregnating solution on the pretreated blended fiber cloth, then move it to an 8...

Embodiment 2

[0067] 1, prepare pretreatment blended fiber cloth according to the method for embodiment 1 step 1;

[0068] 2. Add 35gg-C 3 N 4 Mix with 5g multilayer graphene ball mill for 72h, take it out, wash it twice with ethanol, and dry it at 100°C for 2h to obtain a composite solid lubricant;

[0069] 3, with 10g phenolic-modified epoxy adhesive (solid content 75%), 0.6g nanometer CeO 2 And prepare 3.9g of composite solid lubricant in step 2 and disperse in 65.5g of tetrahydrofuran, fully mix in a high-speed dispersing emulsifier at a speed of 21000r / min to obtain a self-lubricating impregnation solution;

[0070] 4. Apply the self-lubricating impregnation solution on the pretreated blended fiber cloth, then move it to a blast oven at 100°C to dry for 2 hours, and repeat this process until the weight of the pretreated blended fiber cloth increases by 65%, and obtain high-energy radiation-resistant According to self-lubricating fabric liners;

[0071] 5. Finally, paste the above-m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com