High-energy ion injection device

An ion implantation device and high-energy technology, which are applied in the manufacture of discharge tubes, electrical components, semiconductor/solid-state devices, etc., to achieve high-energy ion implantation devices, ensure energy accuracy, and suppress beam divergence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

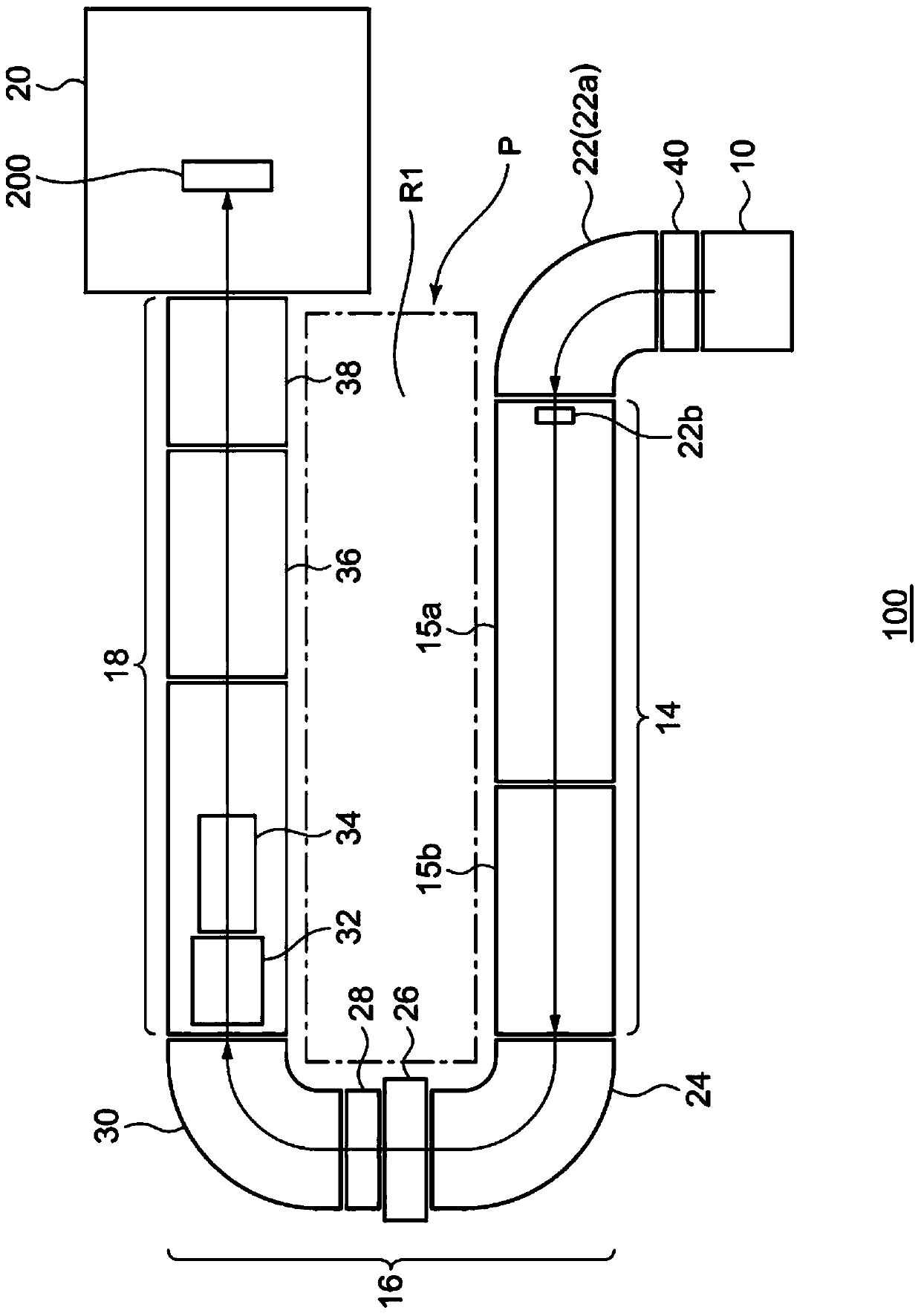

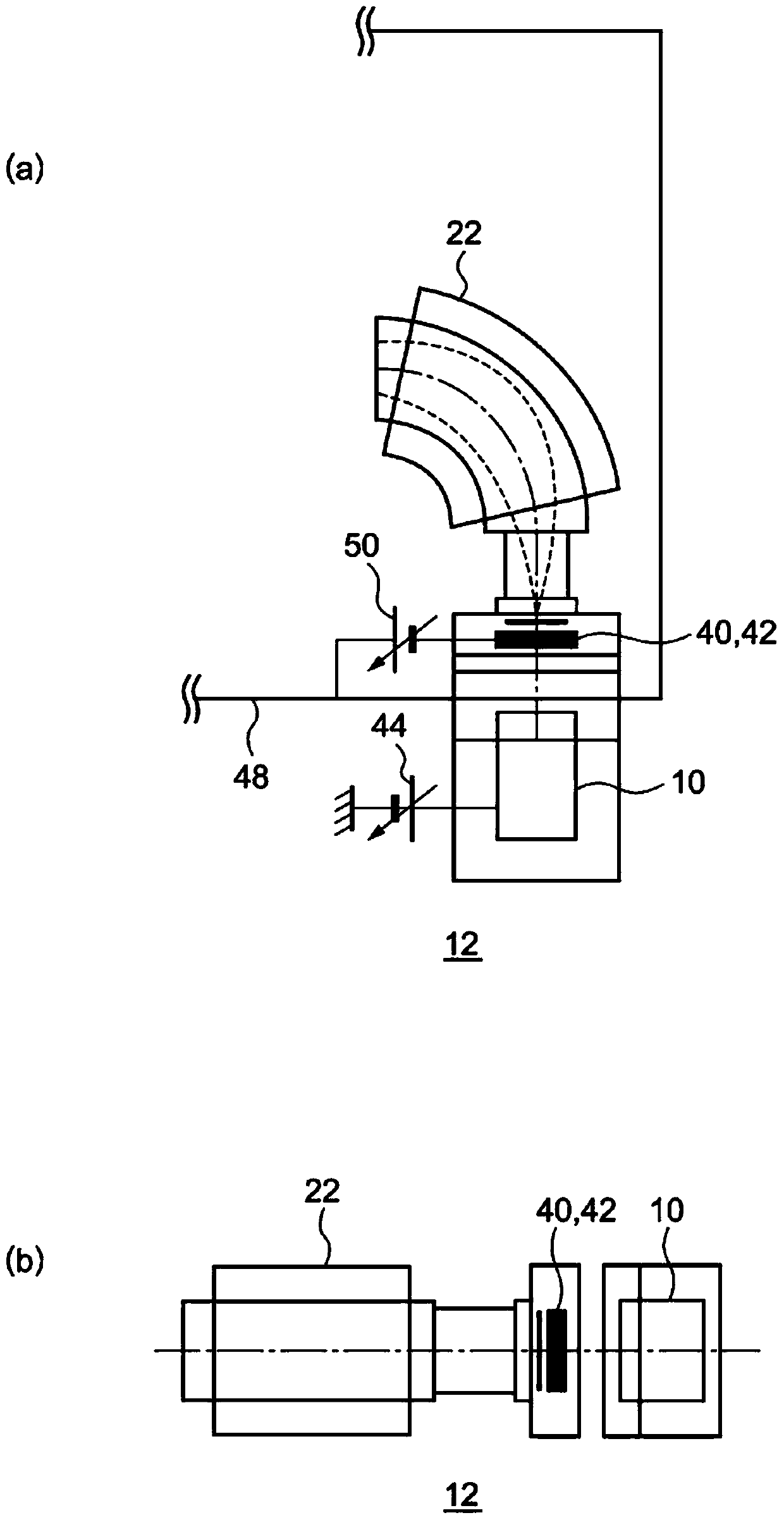

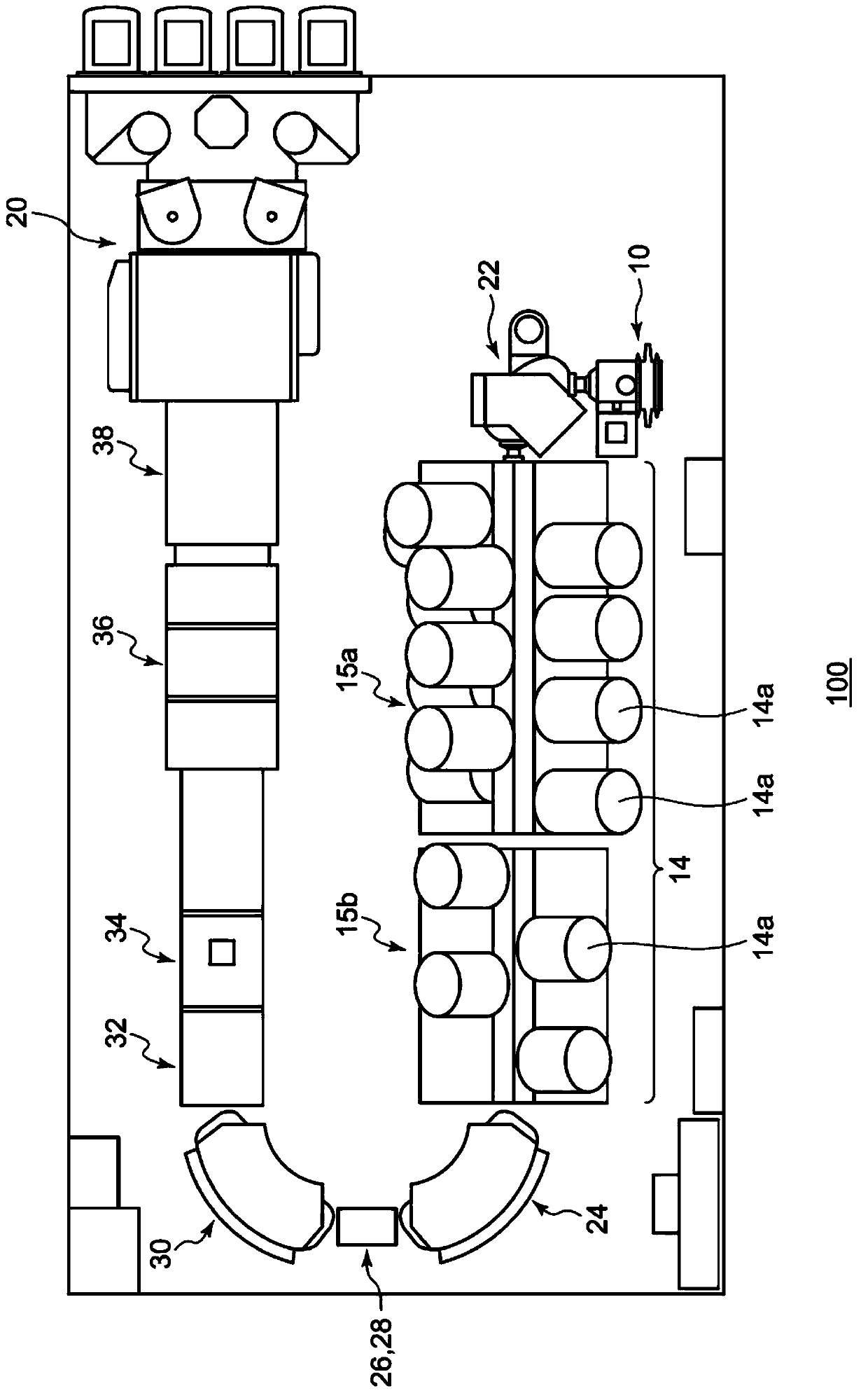

[0051] An example of the high-energy ion implantation apparatus according to this embodiment will be described in more detail below. First, the process by which the present inventors conceived the present invention will be described.

[0052] (parallel magnet)

[0053] A conventional high-energy ion implanter using a parallelizing magnet for parallelizing tracks by a deflection magnetic field has the following problems.

[0054] If high-energy ions are implanted into a wafer with a photoresist layer, a large amount of air leakage will occur, and the molecules of the air leakage will interact with beam ions, and the valence numbers of some ions will change. When the valence changes when passing through the parallelizing magnet, the deflection angle changes, so the parallelism of the beam is broken, and the injection angle toward the wafer becomes different.

[0055] In addition, the amount (number or dose) of implanted ions is obtained by measuring the beam current value with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com