High-ZrO2-content silicate glass and preparing method thereof

A technology of silicate glass and zirconium silicate, which is applied in glass manufacturing equipment, glass furnace equipment, manufacturing tools, etc., can solve the problems of high melting temperature, poor resistance to radiation and alkali metal vapor corrosion, and reduce the The effect of melting temperature, improving radiation resistance, and excellent chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

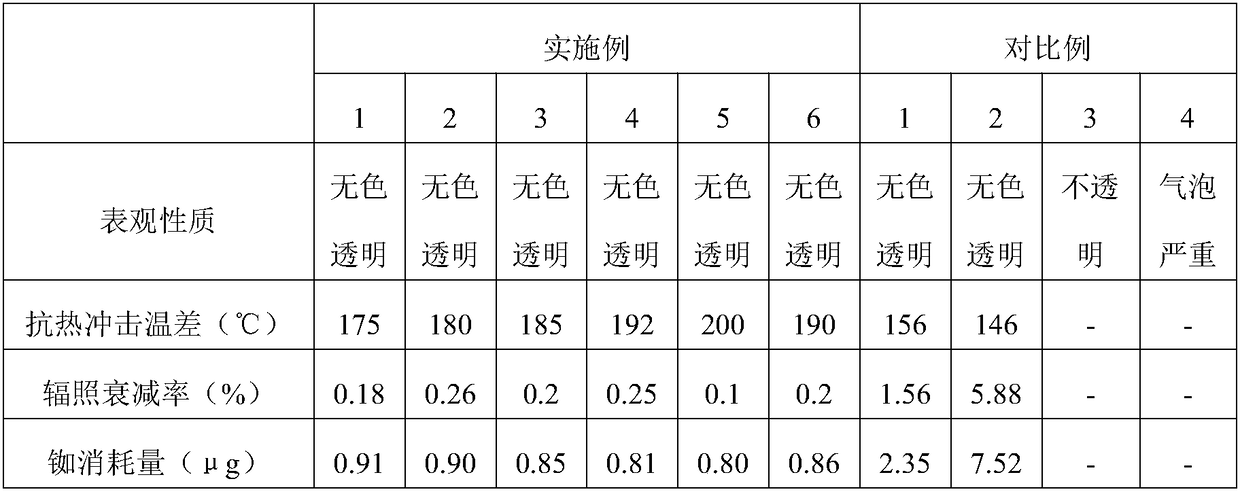

Examples

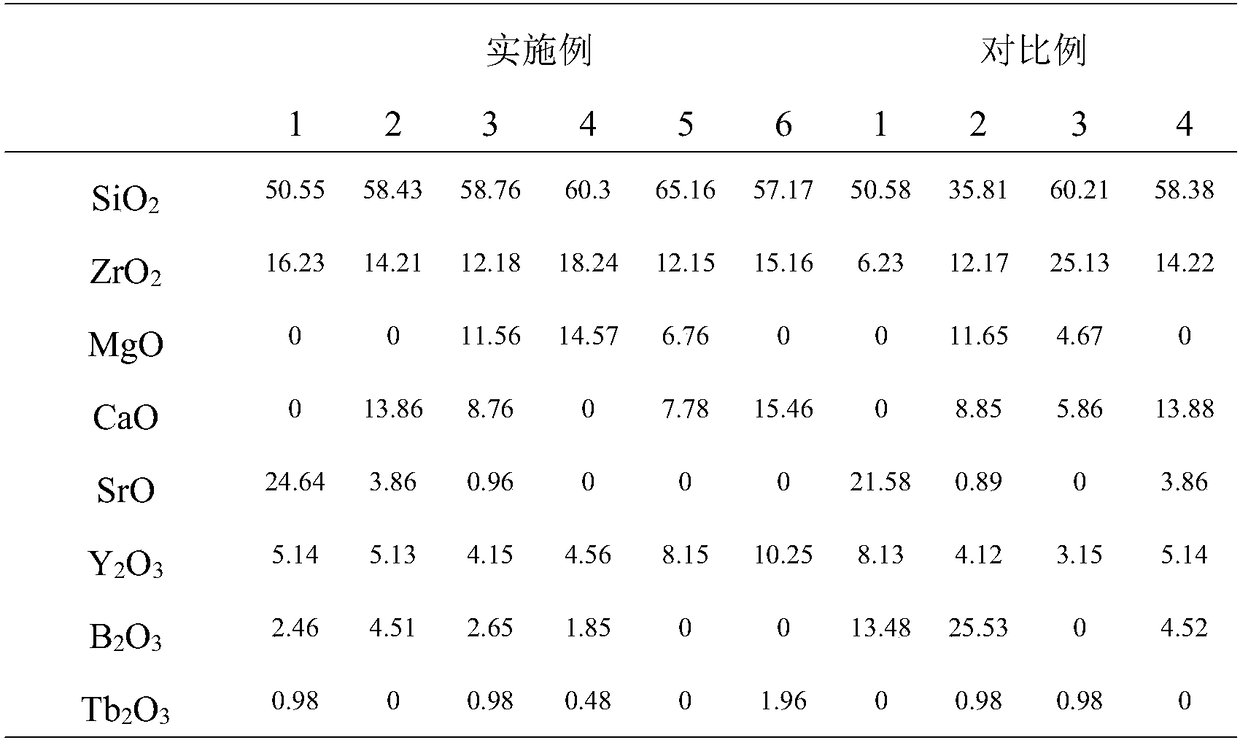

Embodiment 1

[0038] Raw materials were weighed and mixed according to the proportions required in Table 1, wherein, 422.4g of quartz sand, 372.96g of strontium zirconium silicate, 166.12g of strontium carbonate, 50.05g of yttrium oxide, 53.72g of boric acid, and 10.01g of terbium oxide. The mixture was treated at 700°C for 4 hours, cooled and crushed, then placed in a Pt-10Rh crucible and melted at 1560°C at a high temperature. During melting, ultrasonic vibration was performed on the molten glass in different regions. The frequency of the 3 area is 70kHz and the frequency of the upper 1 / 3 area is 20kHz. The glass liquid is stirred upwards with a double-blade stirrer, and the speed of the paddle is 60rpm, and the time is 3h. Lower the temperature to 1380°C for leakage molding, and the corresponding high ZrO can be obtained after annealing 2 content of silicate glass.

Embodiment 2

[0040]Raw materials were weighed and mixed according to the proportioning required in Table 1, wherein, 512.23g of quartz sand, 272.27g of calcium zirconate, 137.61g of calcium carbonate, 57.56g of strontium carbonate, 50.05g of yttrium oxide, and 89.53g of boric acid. The mixture was treated at 500°C for 5 hours, cooled and crushed, put into a Pt-10Rh crucible and melted at 1540°C at a high temperature. During melting, ultrasonic vibration was performed on the molten glass in different regions. The frequency of the 3 area is 80kHz and the frequency of the upper 1 / 3 area is 40kHz. The glass liquid is stirred upwards by using a double-blade stirrer. The speed of the paddle is 40rpm and the time is 6h. Lower the temperature to 1300°C for leakage molding, and obtain the corresponding high ZrO after annealing 2 content of silicate glass.

Embodiment 3

[0042] Weigh and mix raw materials according to the ratio required in Table 1, wherein, 521.99g of quartz sand, 111.11g of magnesium zirconate silicate, 91.29g of calcium zirconate silicate, 27.72g of strontium zirconium silicate, 100.1g of magnesium oxide, and 123.81g of calcium carbonate , yttrium oxide 40.04g, boric acid 53.72g, terbium oxide 10.01g. The mixture is treated at 600°C for 3 hours, cooled and crushed, then put into a Pt-10Rh crucible and melted at 1550°C at high temperature. Ultrasonic vibration is performed on the molten glass in different regions during melting. The frequency of the 3 area is 80kHz and the frequency of the upper 1 / 3 area is 30kHz. The glass liquid is stirred upwards by using a double-blade stirrer. The blade speed is 70rpm and the time is 3h. Lower the temperature to 1320°C for leakage molding, and the corresponding high ZrO can be obtained after annealing 2 content of silicate glass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com