Curable reactive silicone composition, cured product thereof and uses of composition and cured product

A technology of curing reaction and composition, which is applied in the fields of curing reactive silicone composition and its cured product, and heating and melting adhesive materials, which can solve the problems of low adhesiveness of the adherend and achieve high adhesiveness, Excellent gap filling performance and high adhesive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9、 comparative example 1~8

[0390] Using the following components, each component was heat-mixed uniformly with the composition (parts by mass) shown in Table 1, and the hardening reactive silicone composition of the Example and the comparative example was prepared. In each structural formula, Me is a methyl group, and Vi is a vinyl group.

[0391] As (A) component, the following components were used.

[0392] a1-1: (Me 3 SiO 1 / 2 ) 0.46 (SiO 4 / 2 ) 0.54 (HO 1 / 2 ) 0.05

[0393] a1-2: (Me 3 SiO 1 / 2 ) 0.48 (SiO 4 / 2 ) 0.52 (HO 1 / 2 ) 0.04

[0394] a2-1: (ViMe 2 SiO 1 / 2 ) 0.046 (Me 3 SiO 1 / 2 ) 0.394 (SiO 4 / 2 ) 0.56 (HO 1 / 2 ) 0.05

[0395] As (B) component, the following components were used. In addition, the following components starting with B'-1 were used as comparative components.

[0396] B-1: ViMe 2 SiO(Me 2 SiO) 151 SiMe 2 Vi

[0397] B-2: ViMe 2 SiO(Me 2 SiO) 830 SiMe 2 Vi

[0398] B'-1: ViMe 2 SiO(Me 2 SiO) 45 SiMe 2 Vi

[0399] B'-2: ViMe 2 SiO(Me 2 SiO) 47...

Embodiment 10

[0410] The curable reactive silicone composition was prepared according to the following steps 1-4, and it was carried out until sheeting.

[0411] The configuration of the twin-screw extruder used for sheeting and the overall configuration of sheeting are shown in Figure 9 and Figure 10 .

[0412] [Step 1: The step of mixing (A) component and (B) component to obtain a hot-melt solid component]

[0413] Put 2.50 kg of xylene, 6.45 kg of (a1-1) component (white solid at 25°C), and (a2-1) component (white at 25°C) into a cylindrical metal tank (barrel). Solid state) 0.42 kg and (B-2) component 3.13 kg were dissolved and mixed at room temperature using a motor type stirring device.

[0414] The obtained solution was continuously fed at a rate of 10 kg / hr from an input portion provided on the most upstream side of a twin-screw extruder which continuously rotates the screws. Here, the set temperature of the input part was 150 degreeC. Simultaneously, a vacuum pump is used to...

Embodiment 11~19

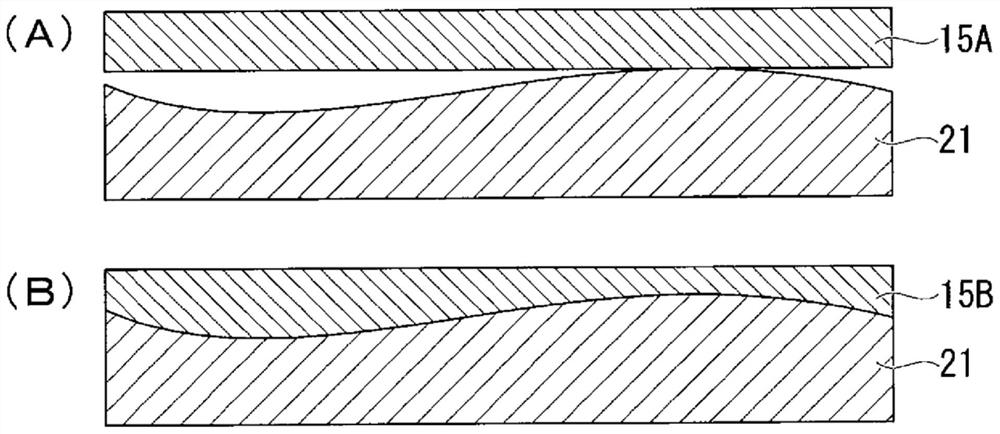

[0427] The kneaded melts obtained in Examples 1 to 9 above were laminated between two peelable films. Next, the laminate was stretched between rolls controlled at a temperature of 80° C. to form a sheet made of a hot-melt curable reactive silicone composition with a thickness of 1 mm and laminated between two release films. The laminated body is cooled by air cooling.

[0428] As a result of separating the peelable film from the obtained laminate, a bubble-free, flat, homogeneous and transparent sheet made of a hot-melt curable reactive silicone composition was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com