Alloy powder for electrode and manufacture method thereof

A technology of alloy powder and manufacturing method, which is applied in electrode manufacturing, battery electrode, active material electrode, etc., can solve the problems of shortening battery cycle life and increasing manufacturing cost, and achieve the effect of good high discharge rate characteristics and short time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] (i) Step 1

[0057] Mix Mm, Ni, Mn, Al and Co according to the specified ratio, and make the composition MmNi in a high-frequency furnace 4.1 mn 0.4 Al 0.3 co 0.4 hydrogen storage alloy ingots. Then, heat treatment was performed at 1060° C. for 10 hours in an argon atmosphere. After the alloy ingot was pulverized into coarse particles, the coarse particles were pulverized into particles with a particle size of 75 μm or less by a wet ball mill in the presence of water to obtain a raw material powder of hydrogen storage alloy with an average particle size of 20 μm.

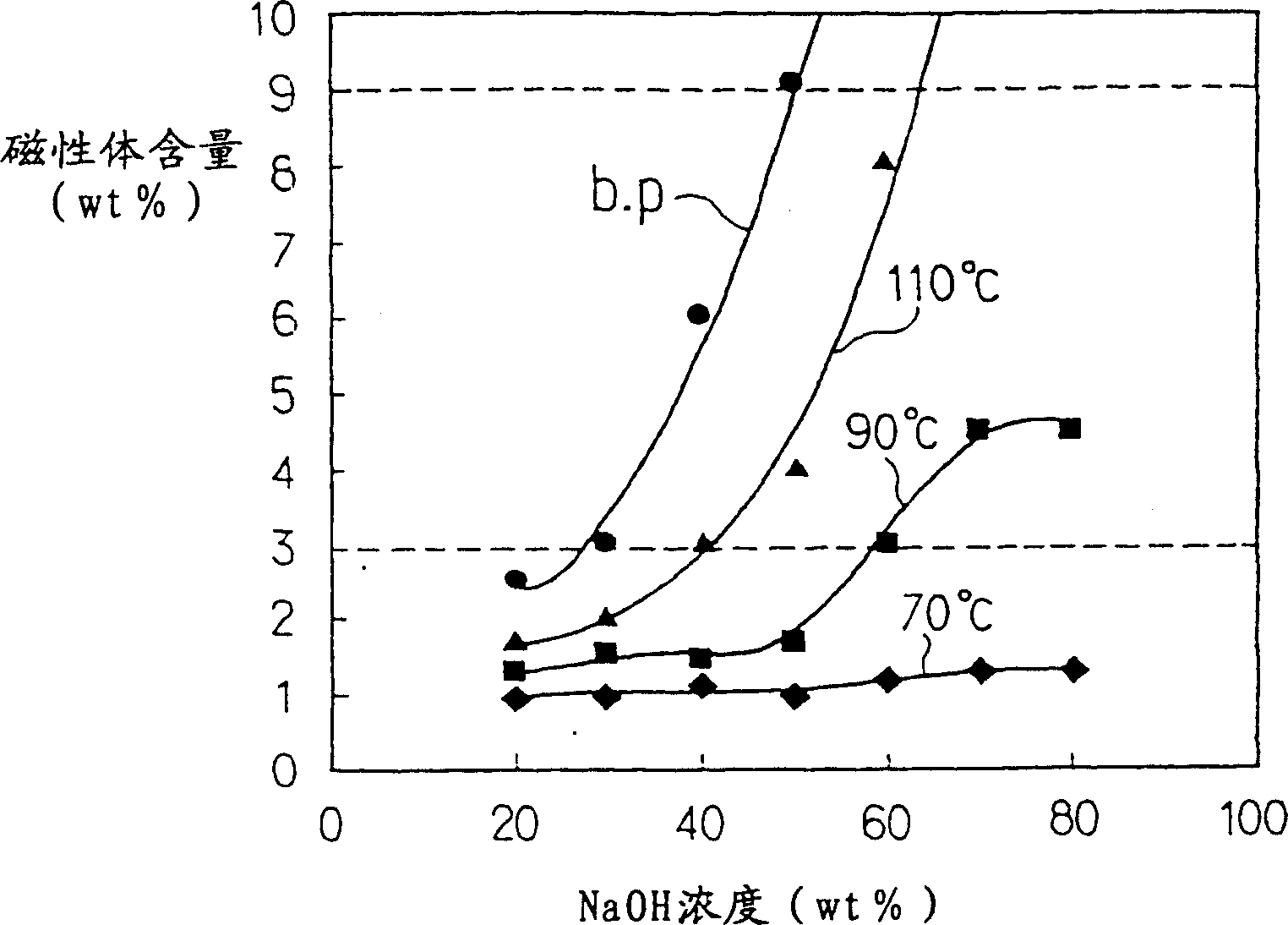

[0058] Next, the obtained raw material powder is subjected to alkaline treatment. That is, the raw material powder is immersed in an aqueous solution of 70° C. to boiling point containing 20 to 80% by weight of NaOH, and stirred for 1 hour. Since the alloy powder produced by the wet ball mill contains moisture, the concentration of NaOH in the aqueous solution should be adjusted to a specified value tak...

Embodiment 2

[0117] Except that the raw material powder formed by the same hydrogen storage alloy used in Example 1 is immersed in the NaOH or KOH aqueous solution of the concentration and temperature shown in Table 3 at the time shown in Table 3, other operations are the same as in Example 1, and obtained Alloy powder for electrodes. Then, the magnetic substance content in the obtained alloy powder for electrodes was measured by the same method as Example 1, and the result is shown in Table 3.

[0118] alkaline substance

type

concentration

(wt%)

temperature

(℃)

time

(Hour)

Magnetic substance content

(wt%)

NaOH

30

90

1

1.5

2

2.3

3

3

40

110

1

3

2

4.5

3

6

80

boiling point

0.1

1.8

0.2

3

KOH

40

110

1

2

...

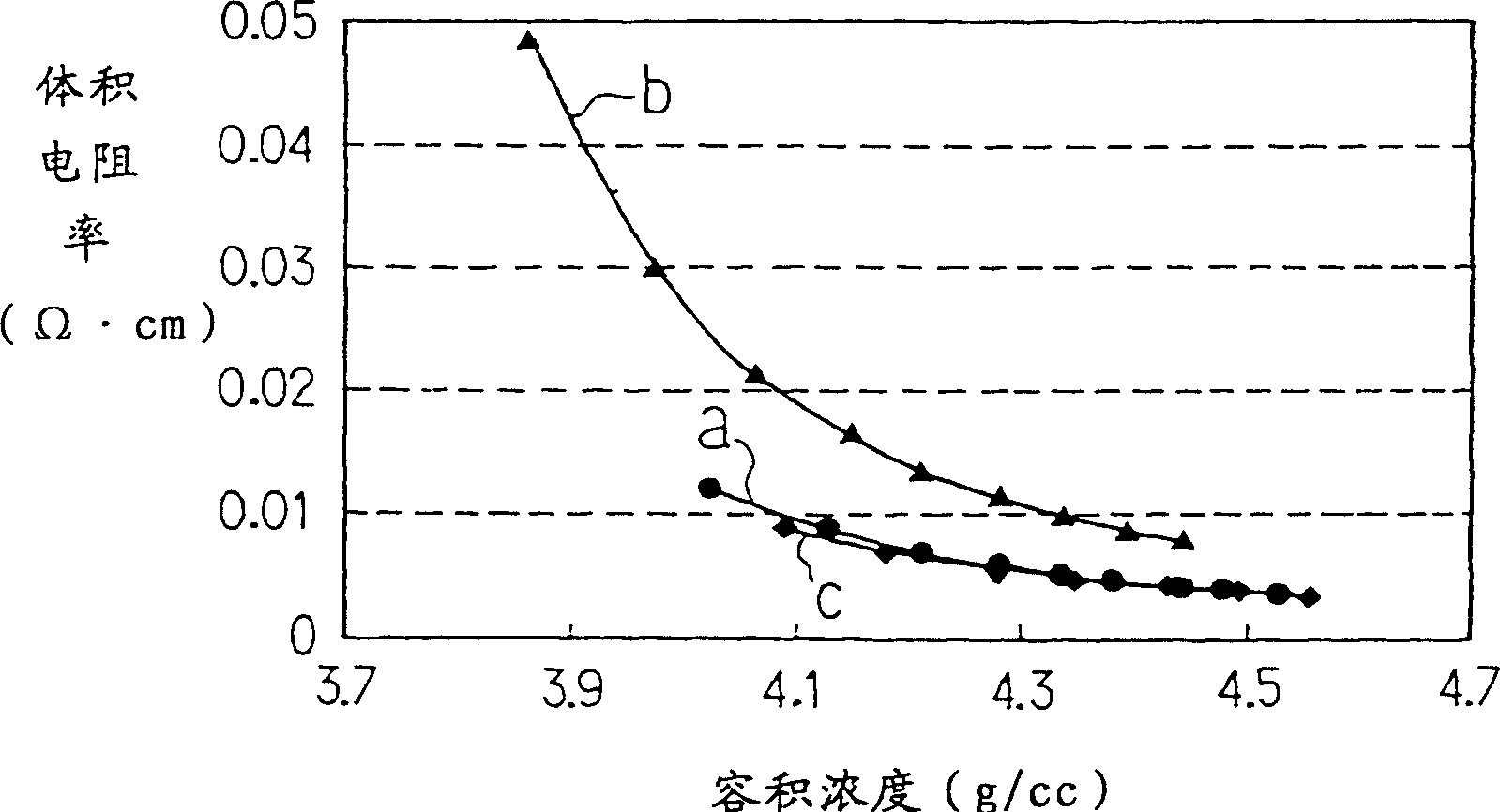

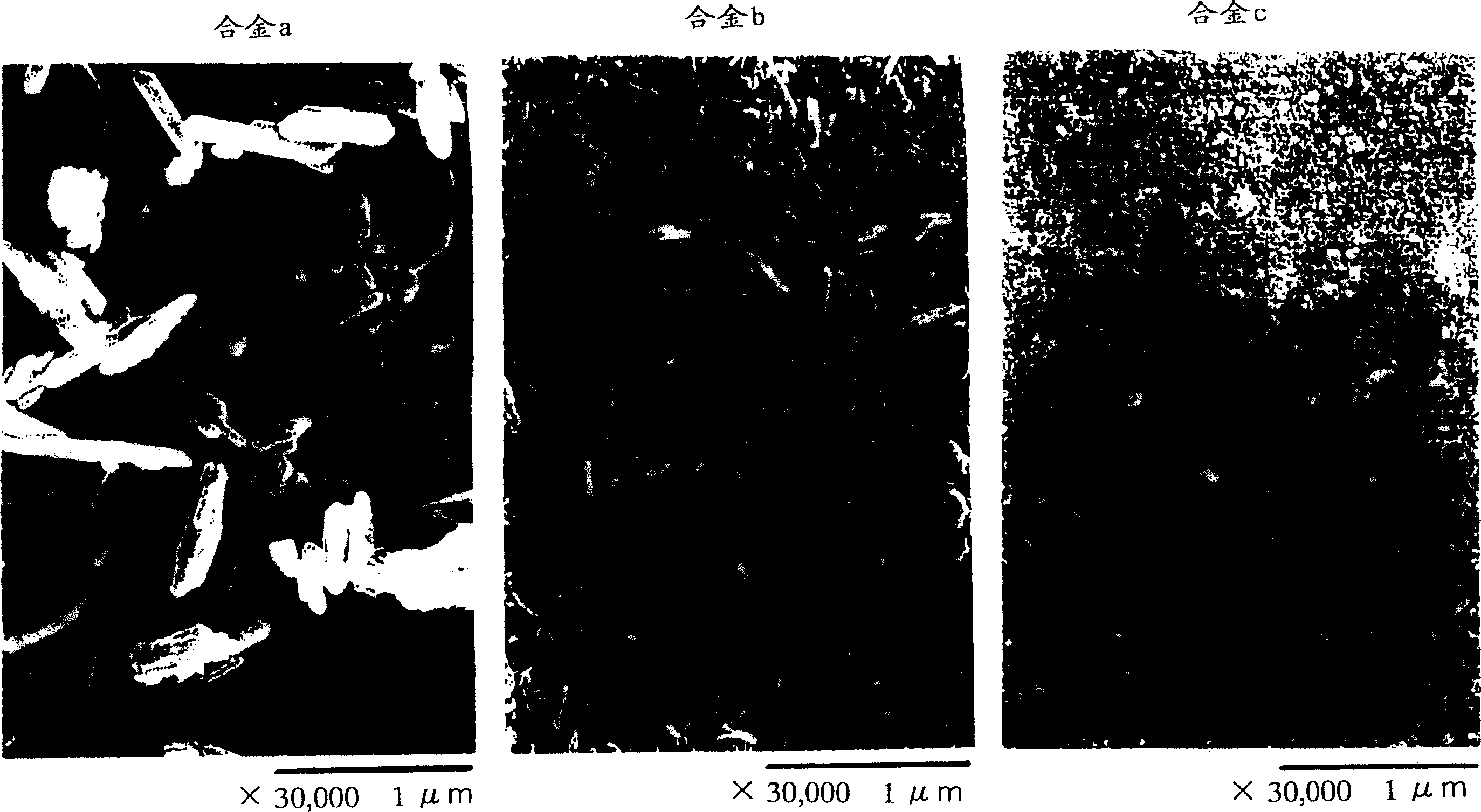

Embodiment 3

[0122] If reduce AB 5 If the amount of Co in the hydrogen storage alloy is low, the corrosion of the hydrogen storage alloy will be accelerated, and the battery life will tend to be shortened. On the other hand, since Co is an expensive metal, it is desired to reduce its usage.

[0123] In Example 1, more Co or Co compounds existed on the surface of the hydrogen storage alloy in the case of using the NaOH aqueous solution than in the case of using the KOH aqueous solution. The alloy powder for electrodes in this state can improve the corrosion resistance of the hydrogen storage alloy matrix in the battery.

[0124] Therefore, when the Co content in the hydrogen storage alloy used in Example 1 was reduced from 5.5% by weight to approximately half of 2.7% by weight, the effect of the present invention was confirmed. The hydrogen storage alloy used here has MmNi 4.0 mn 0.5 Al 0.3 Cu 0.3 co 0.2 composition. In the alkaline treatment, in addition to immersing the aforementi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com