Aerosol spray dispenser tank

An aerosol and spray can technology, applied in spraying devices, liquid spraying devices, packaging, etc., can solve the problems of small final product-producer ratio, user injury, and the top of the generant container falling off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

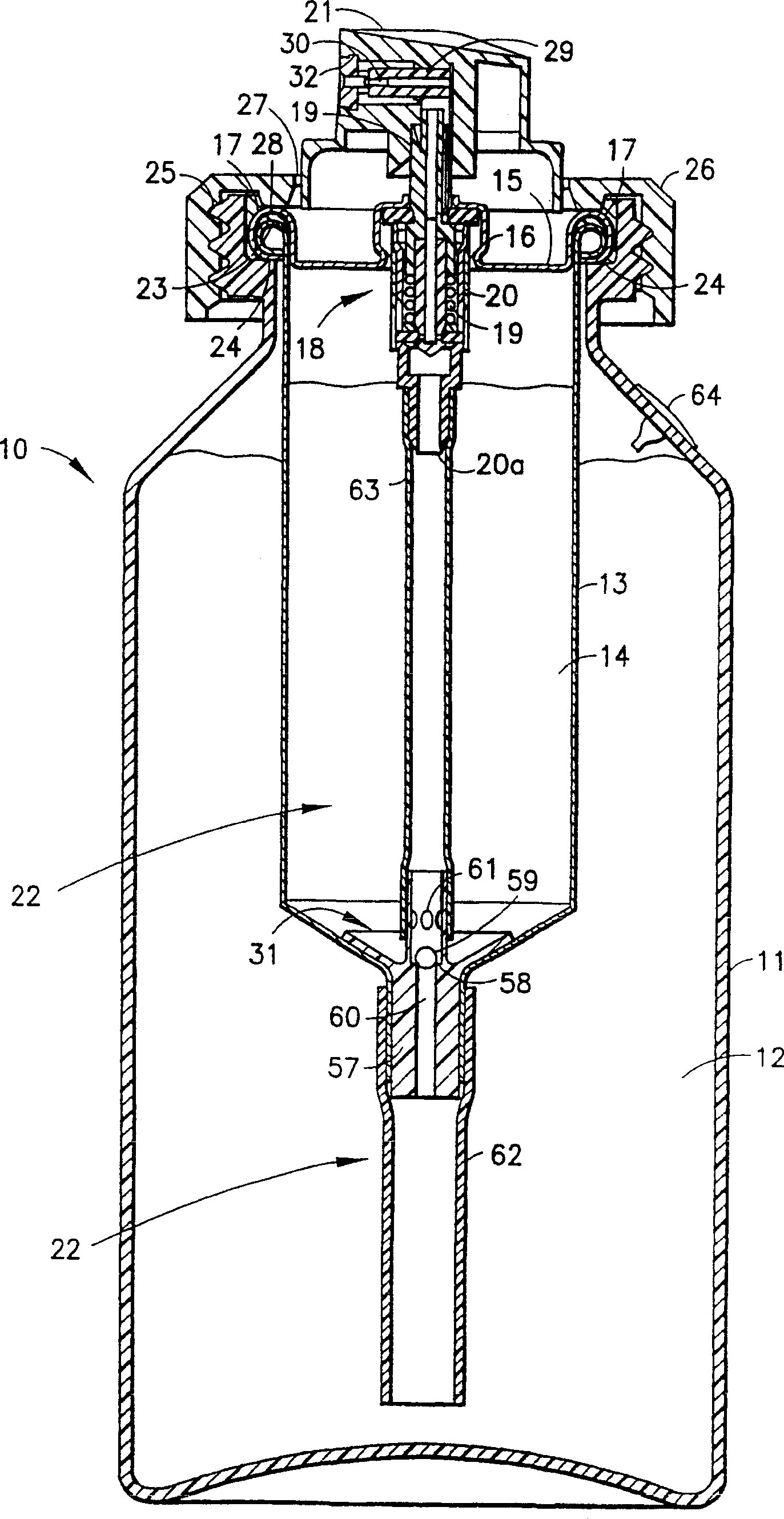

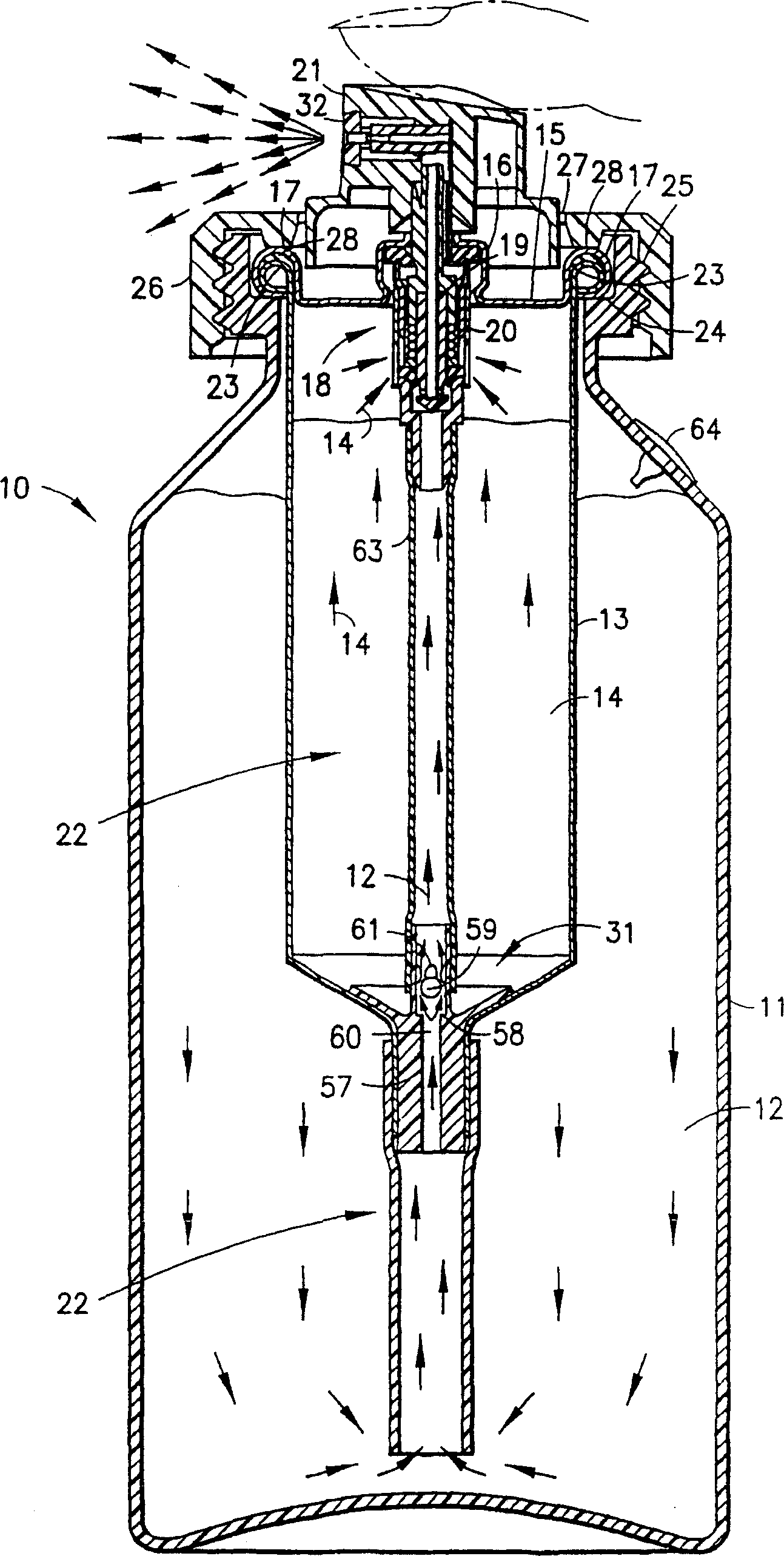

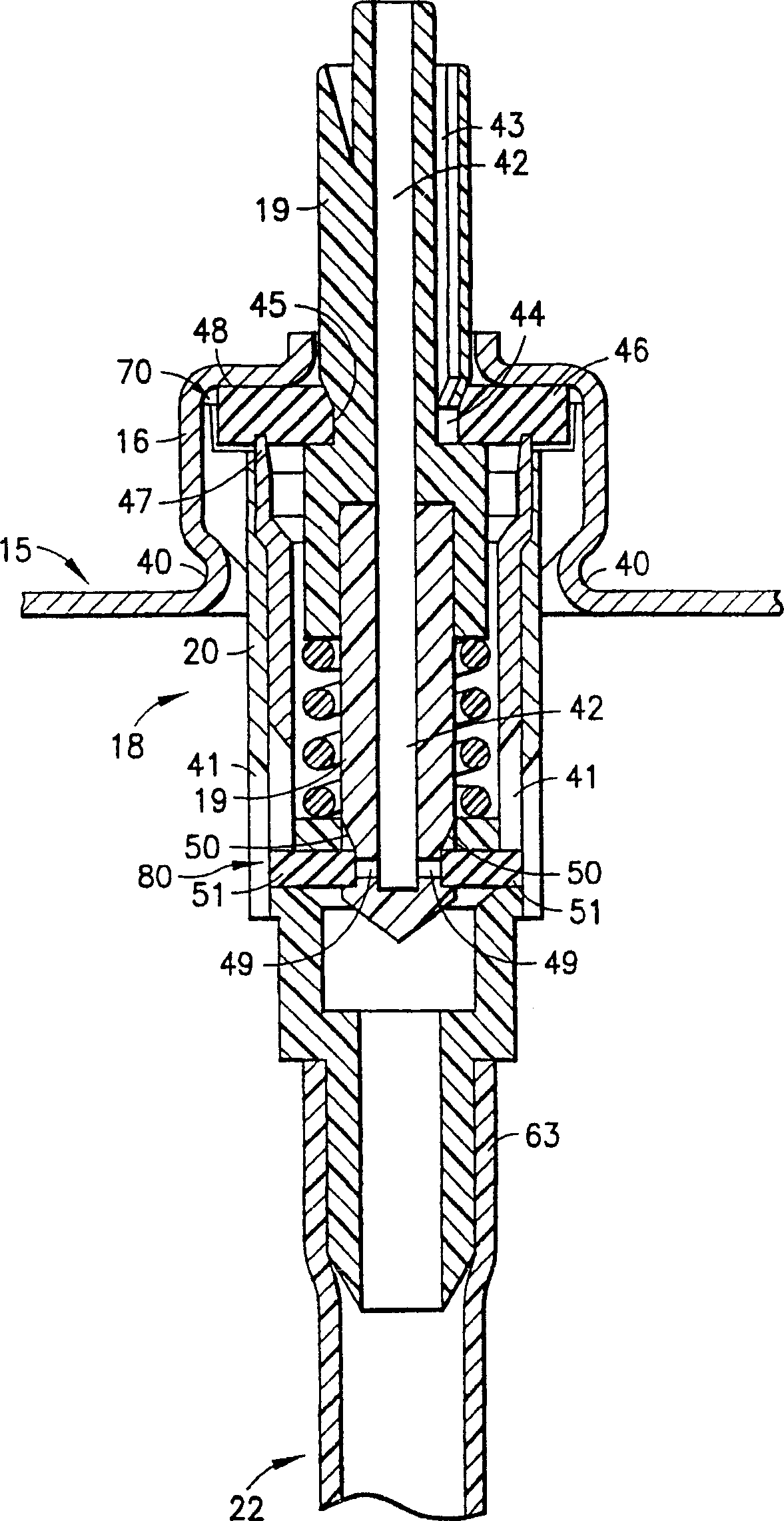

[0020] figure 1 with 2 An aerosol spray can 10 is generally shown having a thin flexible plastic outer container 11 for containing a product 12 to be sprayed. Container 11 can be molded from a variety of plastics in a variety of shapes, sizes and colors to meet market needs. Various graphic characters can also be easily pasted on the outside of the plastic container 11 . The outer container 11 will not hold the pressurized generant, so thin walls are used to reduce manufacturing costs since no substantial wall thickness is required to resist deformation or possible rupture by the generant. Products to be sprayed may include household products, pesticides, herbicides, cosmetics, paints, and the like.

[0021] The inner container 13 is placed inside the outer container 11, and is used to contain a liquid generant 14, which has a liquid phase and an upper layer of a gaseous phase. The inner container 13 will be substantially rigid to withstand deformation under the action of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com